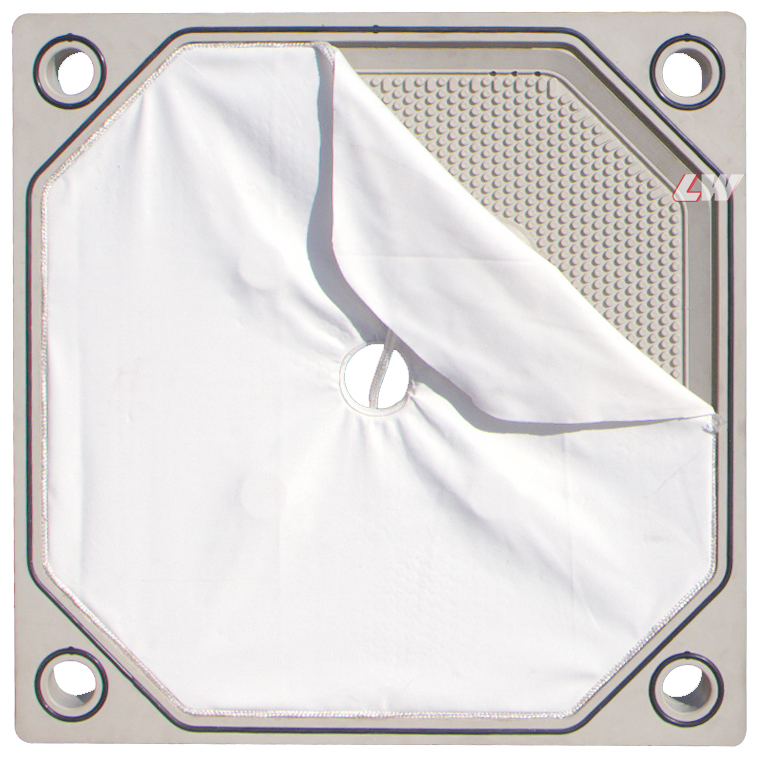

Polypropylene Filter Cloth

Polypropylene filter cloth is a type of synthetic fabric designed for high-performance filtration applications. Made from long fibers, this material is engineered to offer excellent chemical resistance and durability while ensuring high filtration precision. Its smooth surface and superior breathability make it ideal for filtering powders and other particulate matter.

It excels in alkaline-rich applications like dye manufacturing, pharmaceuticals, alumina refining, and sugar processing.

Key Features

✅Excellent Chemical Resistance: Highly resistant to acids and alkalis

✅Lightweight Construction: Lower density compared to other filter materials

✅Temperature Tolerance: Operates effectively at temperatures below 90°C

✅Superior Surface Quality: Smooth surface finish for efficient filtration

✅Excellent Air Permeability: Facilitates optimal flow rates

✅Fine Filtration Capability: Achieves filtration precision below 1 micron

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 100% Polypropylene |

| Temperature Resistance | <90°C |

| Chemical Resistance | Excellent resistance to acids and alkalis |

| Surface Texture | Smooth (long fiber version) |

| Filtration Precision | Down to <1 micron |

| Air Permeability | High |

| Relative Density | Low (lighter than most filter materials) |

Applications

Polypropylene filter cloth is particularly well-suited for industries dealing with strongly alkaline materials, including:

- Dye and chemical processing

- Sugar manufacturing

- Pharmaceutical production

- Alumina processing

- Wastewater treatment

- Mining operations

- Food and beverage production

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Unique Features of Polypropylene Filter Cloth

Acid and Alkali Resistance

exceptional resistance to both acidic and alkaline substances. This resistance not only prolongs the life of the filter cloth but also reduces the risk of contamination and equipment failure.

Lightweight and Durability

Despite its robust performance, polypropylene filter cloth is incredibly lightweight.

Operating Temperature Considerations (<90℃)

polypropylene filter cloth is at temperatures below 90℃.

Superior Breathability for Powder Filtration

The long-fiber construction of polypropylene filter cloth ensures a smooth surface that enhances breathability. This characteristic is especially beneficial for powder filtration.

Manufacturing Process

- Raw Material Selection Premium-grade polypropylene fibers are carefully selected to ensure consistent quality and performance.

- Weaving Technology Advanced weaving techniques create the optimal cloth structure for filtration applications: Precision-controlled weaving patterns, Uniform thread spacing, Consistent thickness throughout.

- Heat Setting: Stabilize dimensions, Enhance mechanical strength, Improve temperature resistance.

- Quality Control: Filtration efficiency, Air permeability Tensile strength, Chemical resistance, Dimensional stability

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What makes polypropylene filter cloth suitable for alkaline materials?

Polypropylene has excellent chemical resistance to alkaline substances, making it ideal for industries processing materials with high pH levels. It maintains structural integrity and filtration efficiency even when exposed to strong alkalis over extended periods.

Q2: What is the typical lifespan of polypropylene filter cloth?

The service life depends on operating conditions, but properly maintained polypropylene filter cloth typically lasts 6-18 months in standard industrial applications. Regular cleaning and proper handling can significantly extend its useful life.

Q3: How do I clean polypropylene filter cloth?

For optimal performance, clean using:

- Low-pressure water spray for initial cake removal

- Mild detergent solutions for stubborn residues

- Thorough rinsing with clean water

- Proper drying before storage or reuse

Avoid harsh chemicals that might damage the cloth structure.

Q4: Can polypropylene filter cloth be used for high-temperature applications?

Polypropylene filter cloth is not recommended for temperatures exceeding 90°C. For higher temperature applications, alternative materials like polyester or PTFE should be considered.

Q5: What is the minimum particle size that can be filtered?

Our polypropylene filter cloth can achieve filtration precision below 1 micron, making it suitable for fine particle separation in demanding applications.

Q6: Is polypropylene filter cloth food-grade compliant?

Yes, our food-grade polypropylene filter cloth meets relevant regulatory standards for food processing applications, ensuring safe contact with food products.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.