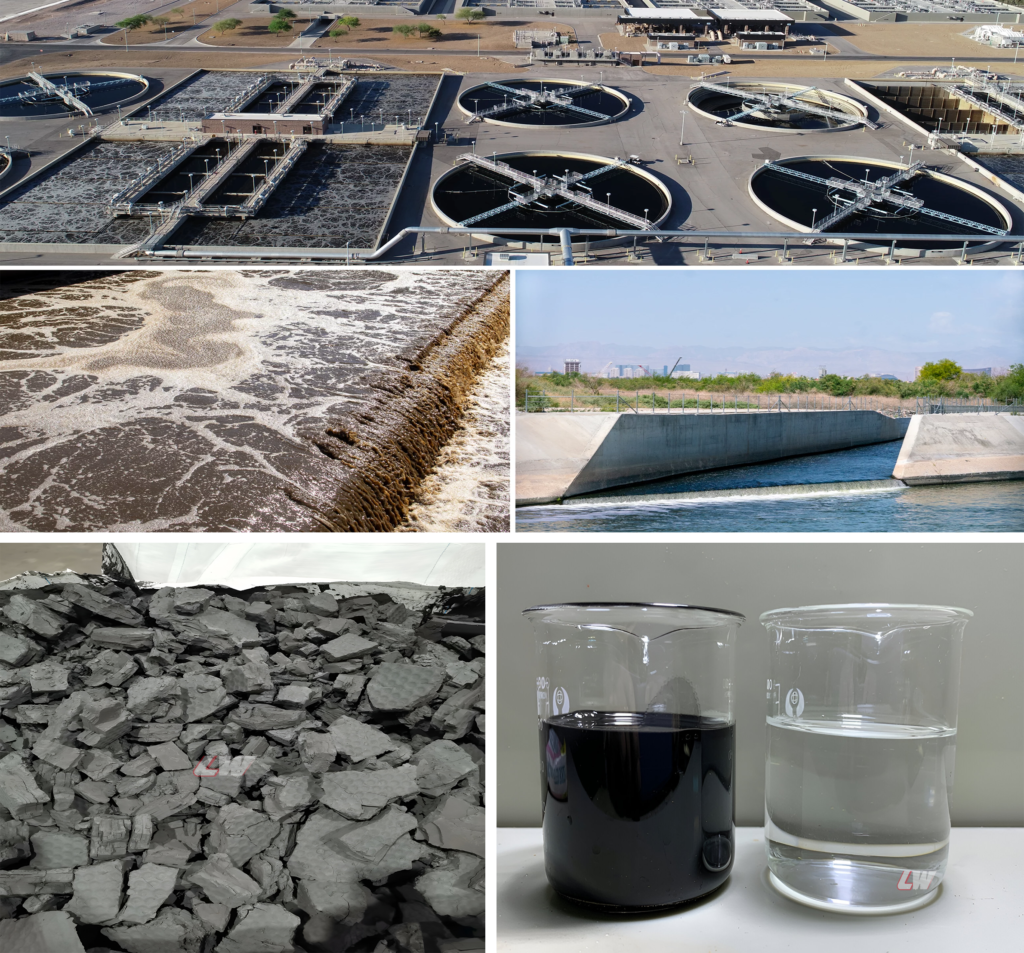

From mechanical bar screens for headworks to advanced dewatering with filter presses, screw presses, and belt presses. Loway Equipment is your direct manufacturing partner for efficient, cost-effective sludge management.

Integrated Solid-Liquid Separation & Wastewater Pre-treatment Solutions for Global Industry

Unbiased Engineering, Premier Manufacturing

Loway Equipment bridges the gap between precision manufacturing and process engineering. Unlike suppliers limited to a single technology, we manufacture the complete spectrum of solid-liquid separation machinery in-house—from pre-treatment units like Mechanical Bar Screens and Rotary Drum Filters, to high-performance sludge dewatering systems including Filter Presses, Screw Presses, and Belt Presses.

This integrated capability gives you two distinct advantages:

- Unbiased Recommendations: Because we build every type of filtraction equipment, we don’t force a “one-size-fits-all” solution. We recommend the exact technology that suits your sludge characteristics.

- Direct Factory Control: By managing the entire production lifecycle in our own facility—from raw steel laser cutting to final PLC programming—we ensure every machine meets international standards while offering factory-direct value.

Loway filter press equipment is designed and manufactured to the highest standards of quality and precision.

Only the highest-grade materials and manufacturing processes are used to ensure reliability.

Loway offers customizable solid liquid equipment solutions to meet your unique operational needs.

Loway team is committed to offering comprehensive support long after your purchase.

Comprehensive Dewatering & Screening Technologies

Sludge Dewatering

Multi-Disk Screw Presses (Volute Dewatering)

Ideal for: Oily Sludge, Food Processing, DAF Sludge Engineered for continuous, unmanned operation, our Screw Press utilizes a self-cleaning moving ring mechanism that prevents clogging. It is the superior choice for oily and greasy sludge where traditional filter cloths would blind. With low energy consumption and minimal water usage, it offers a "plug-and-play" solution for 24/7 automated plants.

Chamber & Membrane Filter Presses

Ideal for: Mining Tailings, Chemical Processing, Stone Cutting When maximum cake dryness is the priority, the Loway Filter Press is unmatched. Our high-pressure designs (up to 30 bar) and membrane squeeze technology extract the maximum amount of liquid, significantly reducing transportation and landfill costs. We offer fully automated plate shifting and cloth washing systems to reduce labor intensity.

Belt Filter Presses

Ideal for: Large-Scale Municipal Sewage, Paper & Pulp Designed for high-volume handling capacity, our Belt Filter Press provides a reliable, continuous dewatering solution. Featuring heavy-duty rollers and high-quality filter belts, this system is perfect for treating large quantities of municipal sludge or wastewater with high organic content, ensuring consistent throughput and low polymer consumption.

Pre-treatment & Screening

Mechanical Bar Screens

Ideal for: WWTP Headworks, Pump Protection Effective treatment starts at the inlet. Our range of coarse and fine Mechanical Bar Screens (Rotary Drum, Rake type) effectively removes debris, rags, and large solids. This critical pre-treatment step protects downstream pumps and dewatering equipment from damage and blockage, ensuring the longevity of your entire treatment plant.

Rotary Drum Filters

Ideal for: Aquaculture (RAS), Food Processing, Water Intake Screening Bridging the gap between coarse screening and sludge dewatering, our Rotary Drum Filter removes fine suspended solids (TSS) from large water flows. Featuring high-precision wedge wire screens, it continuously separates organic matter and particles that pass through standard bar screens. This is essential for protecting sensitive biological systems in aquaculture and reducing load in industrial water recovery.

Accessories & System Integration

Ideal for: Plant Maintenance, System Upgrades, Spare Parts Inventory Ensure peak performance and minimize downtime with genuine Loway components. From custom-sewn filter cloths and replacement filter plates (PP/Cast Iron) to matched screw pumps and conveyors, we offer one-stop sourcing. Our accessories are engineered to integrate seamlessly with your main equipment, guaranteeing system synchronization and simplifying your supply chain.

Precision Engineering in Filter Presses, Belt Filter Presses, Screw Presses, and Bar Screens

With over 25 years of expertise, we empower wastewater treatment plants, mining operations, and chemical industries worldwide to achieve efficient, reliable, and sustainable sludge dewatering and solid-liquid separation processes.

Providing high-quality industrial dewatering systems to power your operations with precision, reliability, and efficiency

Streamlined Process for Your Success

We make ordering complex industrial equipment simple and transparent.

Step 1: Analysis & Consultation

Send us your water parameters or sludge type. Our engineers analyze your needs to recommend the most cost-effective equipment model.

Step 2: Proposal & Design

We provide a detailed technical proposal, including CAD layout drawings, flow charts, and a clear quotation—no hidden costs.

Step 3: Manufacturing & QC

Once production begins, we share weekly progress reports with photos. Every machine undergoes a strict dry-run test before leaving our factory.

Step 4: Delivery & Support

We handle professional export crating and logistics. Upon arrival, we provide installation manuals, video guides, or on-site engineer support.

Which Dewatering Technology is Right for You?

Making the wrong choice can lead to high operating costs. Here is a quick comparison based on our engineering data.

Feature | Screw Press | Filter Press | Belt Press |

Best For | Oily/Greasy Sludge | Inorganic/Mining Sludge | Large Municipal Flows |

Cake Dryness | Good (15-25%) | Highest (30-60%+) | Moderate (18-25%) |

Operation | Continuous / Auto | Batch Cycle | Continuous |

Maintenance | Very Low | Moderate | Moderate |

Footprint | Compact | Large | Medium |

Why Choose us

Industry Expertise: Our team is highly skilled in designing and manufacturing solid-liquid separation solutions for various industries, ensuring that you receive the best products for your needs.

Cutting-Edge Technology: We use the latest advancements in filtration technology to deliver high-performing, durable systems.

Global Customer Base: From small businesses to large enterprises, we provide tailored dewatering solutions for companies all around the world.

We are proactive in ensuring that our supply chain can supply the high-quality materials needed for us to perform at the highest levels to meet our customers’ requirements.

We continuously invest in research and development, pushing the boundaries of filtration technology.

Our technologies are designed to minimize environmental impact and maximize operational efficiency.

Striving for the highest standards in design, engineering, and manufacturing.

Every product undergoes rigorous testing and meets international manufacturing standards.

We view each client partnership as a collaborative journey of technological advancement.

Promoting environmentally friendly solutions through energy-efficient filtration systems.

Building long-term relationships by understanding and meeting customer needs.

Rapid response team for emergencies, spare parts, and process optimization.

The Direct Manufacturer Advantage

Direct-from-Factory Pricing

By eliminating trading companies and middlemen, Loway Equipment offers competitive pricing without compromising on quality. You deal directly with the source, ensuring clear communication and faster lead times.

Custom OEM & ODM Capabilities

We understand that every facility layout is unique. Our engineering team supports OEM partners and Engineering Procurement Construction (EPC) firms by customizing equipment dimensions, electrical components (Siemens/Schneider/ABB), and materials (SS304/SS316L) to meet strict project specifications.

Applications Across Industries

We are proud to have worked with clients from diverse industries, providing tailored filtration solutions that improve efficiency, reduce costs, and enhance operational performance.

Trusted by Industries Worldwide

Reliable After-Sales & Spare Parts Supply

Global Component Standard

We design our machines using universal standards. Key components like bearings and motors are compatible with major international brands, making local replacement easy.

Fast Dispatch

We maintain a large inventory of essential consumables—filter cloths, plates, screw shafts, and belts—ready for immediate air shipment via DHL/FedEx.

Video Training Library

Access our exclusive library of maintenance videos, teaching your team how to change filter cloths or adjust belt tension step-by-step.

Frequently Asked Questions

Q1: I am unsure which equipment suits my sludge (Screw Press vs. Filter Press). How do I decide?

The choice depends on your specific sludge characteristics and operational goals.

Choose a Multi-Disk Screw Press if you are handling oily sludge (DAF), food waste, or need 24/7 continuous, unmanned operation with low energy costs.

Choose a High-Pressure Filter Press if your priority is maximum cake dryness (lowest moisture) to reduce hauling costs, typically for mining tailings, chemical processing, or stone cutting wastewater.

Choose a Belt Filter Press for large-scale municipal sewage where high throughput volume is the main requirement.

Still unsure? Send us a 2L sludge sample, and our lab will perform a free filtration analysis to recommend the best technology.

Q2: Do you support OEM manufacturing? Can you match our specific component brands?

Yes, Loway is a premier OEM partner for many global engineering firms and distributors. We can manufacture equipment under your private label.

Crucially, we offer Component Flexibility. While our standard units use top-tier Chinese brands, we can integrate specific international brands (e.g., Siemens/Allen-Bradley for PLCs, SEW/Nord for drives, Schneider/ABB for electrics) to match your local site standards and spare parts inventory.

Q3: How do you ensure the equipment fits into our existing facility?

We don’t just sell standard models; we engineer solutions. Before manufacturing, our engineering team will provide detailed 3D CAD drawings and foundation layouts. We can customize the frame dimensions, piping orientation (left/right inlet), and hopper height to fit tight spaces or retrofit existing installations seamlessly.

Q4: What is your solution for international after-sales support and spare parts?

We understand the “distance anxiety” of importing machinery.

Standardized Parts: We design our machines using universal standards (bearings, seals, motors), so 90% of wear parts can be sourced locally.

Emergency Stock: For specialized parts (like filter plates or screw shafts), we maintain a ready-to-ship inventory for immediate air freight.

Remote Support: Our PLC systems can be equipped with a remote access module, allowing our engineers to troubleshoot software or logic issues instantly from our office in China.

Q5: Can you provide a complete turnkey system, not just the bare machine?

Absolutely. We specialize in Skid-Mounted Integrated Solutions. We can package the dewatering machine with the matching feed pump, polymer dosing unit, pipework, and central control panel—all pre-wired and mounted on a single steel base. This “Plug-and-Play” design reduces your on-site installation time and costs by up to 60%.

Q6: How is the equipment packaged to prevent damage during sea freight?

We take packaging as seriously as manufacturing. All sensitive components (motors, panels) are packed in export-grade plywood crates (fumigation-free). Large frames are wrapped in heavy-duty industrial film for moisture protection and securely lashed/bolted to the container floor to prevent movement. We guarantee the equipment arrives in factory-new condition.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning, and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.