Diaphragm Filter Plates

Diaphragm filter plates represent a cutting-edge technology in the filter press industry, offering superior performance in solid-liquid separation processes. These specialized components enhance filtration efficiency while reducing processing time and operational costs across multiple industries.

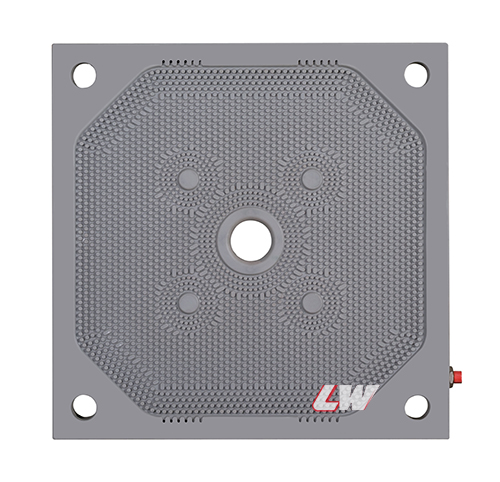

Diaphragm filter plates consist of a base plate and a flexible membrane. When external media (water or compressed air) enters the chamber between the plate and membrane, the membrane inflates to compress the filter cake formed in the chamber between diaphragm plates and chamber plates. This compression significantly improves solid-liquid separation efficiency and increases the solid content percentage of the filter cake.

Key Features

✅ High Tensile Strength & Elongation:

Constructed with precision, our diaphragm filter plates boast high tensile strength and exceptional elongation, ensuring reliable performance under demanding operational conditions.

✅ High Temperature & Corrosion Resistance:

Designed to withstand extreme temperatures and corrosive environments, these filter plates maintain their integrity and functionality, even in harsh industrial settings.

✅ Innovative Design:

The diaphragm filter plate comprises a template and a matching plate. This assembly guarantees optimal performance, creating a tightly sealed chamber when integrated with a casing filter plate. The design effectively enhances the mechanical compression of the filter cake, leading to improved dewatering and filtration efficiency.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Options | Rubber, Polypropylene |

| Temperature Resistance | Up to 120°C (depending on material) |

| Pressure Capacity | 6-16 bar |

| pH Range | 1-14 (material dependent) |

| Membrane Thickness | 2-5mm |

| Plate Sizes | 630×630mm to 2000×2000mm |

Types of Diaphragm Filter Plates

Rubber Diaphragm Filter Plates

- Membrane is embedded in core plate grooves

- Easy to disassemble and replace

- High elasticity makes them resistant to damage

- Ideal for applications requiring frequent maintenance

Polypropylene Diaphragm Filter Plates

- Manufactured through integrated welding process

- Non-replaceable membrane

- Excellent chemical resistance

- Suitable for harsh chemical environments

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Benefits of Using Diaphragm Filter Plates

Shorter Filtration Time

As filtration progresses, cake growth typically slows, requiring longer processing times to achieve low residual moisture content. Diaphragm filter plates significantly reduce filtration time through mechanical compression via the elastic membrane, achieving desired moisture levels faster than conventional systems.

Reduced Washing Time

Conventional filtration components often cause uneven cake formation due to wrinkling or cracking, resulting in inconsistent washing. Diaphragm filter plates prevent this unevenness through gentle membrane pressure during the washing process. The uniform capillary structure formed in the filter cake ensures excellent washing effectiveness while substantially reducing washing liquid consumption.

Lower Residual Moisture Content

The high-pressure filtration process is replaced by compression from the highly elastic membrane against the filter cake. This compression occurs perpendicular to the filtration surface rather than along it. The result is significantly reduced residual moisture content and increased filtrate discharge in a shorter timeframe.

Key Parameters

While exact specifications can vary based on application and design, our diaphragm filter plates generally offer the following parameters:

- Tensile Strength: High-performance rating for industrial demands.

- Elongation: Superior elasticity ensuring minimal damage under pressure.

- Temperature Resistance: Capable of operating in high-temperature environments.

- Corrosion Resistance: Suitable for use in corrosive conditions, extending product lifespan.

- Material Options: Available in both rubber and polypropylene, catering to specific operational needs.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How do diaphragm filter plates compare to traditional filter plates?

Diaphragm filter plates provide superior performance through additional mechanical compression, resulting in drier filter cakes, faster cycle times, and reduced washing liquid consumption compared to traditional plates.

Q2: What industries benefit most from diaphragm filter plates?

Industries processing slurries with high moisture content or valuable solids particularly benefit from these plates, including mining, chemical processing, pharmaceutical manufacturing, and wastewater treatment.

Q3: How long do diaphragm filter plates typically last?

With proper maintenance, rubber diaphragm plates typically last 1-3 years, while polypropylene versions may last 3-5 years depending on operating conditions and the nature of processed materials.

Q4: Can membranes be replaced or must the entire plate be replaced?

Rubber diaphragm plates feature replaceable membranes, while polypropylene versions typically require complete plate replacement when the membrane fails.

Q5: What pressures can diaphragm filter plates withstand?

Our diaphragm filter plates are engineered to withstand operating pressures between 6-16 bar, depending on the specific model and application requirements.

Q6: Are these plates compatible with existing filter press systems?

Most diaphragm filter plates can be integrated into existing filter press systems with minimal modifications, though compatibility should be verified based on specific dimensions and connection types.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.