High-Performance Filter Cloths: Engineered for Precision & Easy Cake Release

Optimize your filter press operations with our premium woven fabrics. From Monofilament for fast drainage to Multifilament for fine particle capture, we custom-fabricate cloths to fit any plate size with zero leakage.

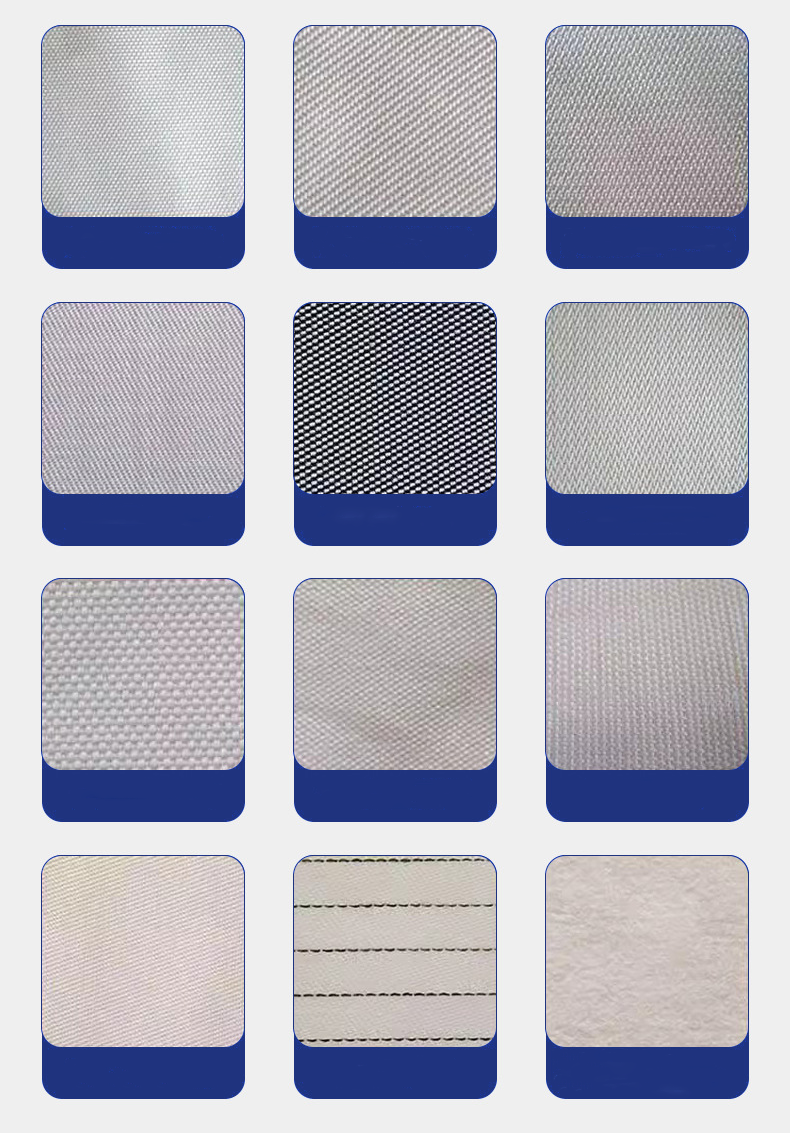

Woven for Performance: Our Cloth Types

The right weave determines your filtration speed, clarity, and cake moisture.

1. Choose the Yarn Structure (Performance)

Monofilament Filter Cloths (The "Anti-Clogging" Choice)

- Structure: Woven from single, smooth extruded fibers (like fishing line).

- Filtration Effect: Extremely low flow resistance. The smooth surface ensures instant cake release (non-stick) and prevents blinding.

- Best For: Sticky sludge, mining tailings, and high-volume wastewater where fast cycle times are critical.

Multifilament Filter Cloths (The "High-Capture" Choice)

- Structure: Woven from twisted bundles of fine fibers.

- Filtration Effect: The complex fiber matrix traps ultra-fine particles, delivering superior filtrate clarity.

- Best For: Chemical pigments, dyestuffs, and industries requiring very clean filtrate.

Mono-Multi Composite Cloths (The "Balanced" Choice)

- Structure: Monofilament warp + Multifilament weft.

- Filtration Effect: Combines the strength and drainage of monofilament with the retention accuracy of multifilament.

- Best For: Complex industrial wastewater needing both speed and clarity.

2. Choose the Polymer (Survival)

Polypropylene multifilament 750 A

Polypropylene monofilament 2025

Polypropylene monofilament 4518

Polypropylene monofilament 108B

Polyester multifilament 621

Polyester multifilament 3927

Polyester multifilament 47

Nylon monofilament

Anti-static filter cloth

Polypropylene needle-punched

filter felt

Polypropylene multifilament 750 B

Polypropylene multifilament 750 AB

Choosing the right polymer is the first step to longevity.

Material | Temp. Limit | Acid Resistance | Alkali Resistance | Abrasion Resistance | Ideal Application |

Polypropylene (PP) | 90°C | Excellent | Excellent | Good | General Standard. Covers 80% of chemical/mining uses. |

Polyester (PE) | 130°C | Excellent | Poor | Good | High-temp acidic slurries (e.g., Metal Finishing). |

Nylon (PA) | 100°C | Fair | Good | Best | Highly abrasive slurries (e.g., Stone cutting, Mining). |

3. Configuration & Mounting Styles

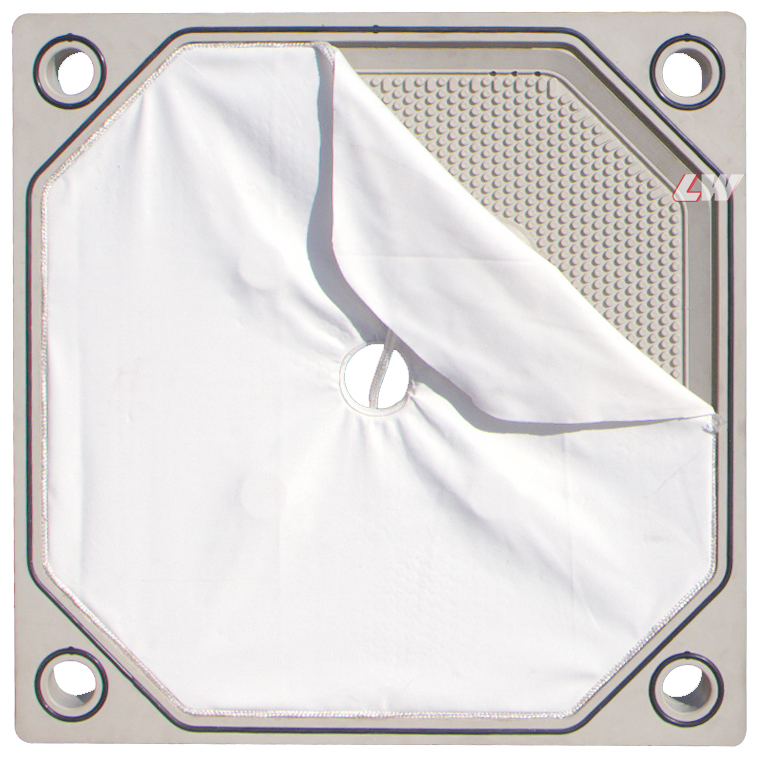

1. Barrel Neck Design (The Modern Standard)

Description: Two cloths connected by a seamless fabric or rubberized tube.

Advantage: Zero Bypass. The tight neck seal prevents slurry from leaking into the filtrate. Easier and faster to install than old-style “butterfly” cloths.

Ideal For: Modern Chamber and Membrane filter presses.

2. CGR (Gasketed) Design

Description: Features a rope (cord) sewn into the edge of the cloth, which is hammered into a groove on the plate.

Advantage: 100% Leak-Free. No liquid drips from the plate pack.

Ideal For: Chemical, Pharma, and toxic applications requiring a hermetic seal.

3. Overhang / Butterfly Design

Description: Single cloths or two cloths tied together with straps.

Advantage: Simple and low cost. Fits older style presses or simple plate-and-frame designs.

Ideal For: Legacy equipment and manual discharge presses.

Loway Filter Cloth Categories

Filter press cloths are essential components in solid-liquid separation processes across various industries. These specialized textiles serve as the primary filtration medium in filter press systems, allowing liquids to pass through while capturing solid particles. The proper selection of filter press cloths directly impacts operational efficiency, filtration quality, and equipment longevity.

Monofilament filter cloth is a high-performance filtration material widely used in various industries. It is known for its excellent filtration efficiency, breathability, durability, and easy maintenance.

Nylon filter cloth, also known as polyamide filter cloth, With its excellent alkali resistance, mild acid resistance, and outstanding mechanical strength, it is a preferred choice for various industries requiring efficient and durable filtration solutions.

Bonded filter cloth is a type of filter media that uses advanced adhesive bonding to ensure high filtration efficiency, minimal leakage, and improved operational safety.

It offers exceptional resistance to acids, weak alkalis, and high temperatures (up to 130°C). Its smooth surface, superior wear resistance, and excellent breathability make it a top choice for industries. With filtration precision as fine as 5 microns, it ensures optimal solid-liquid separation for diverse applications.

Polypropylene filter cloth is a type of synthetic fabric designed for high-performance filtration applications. Made from long fibers, this material is engineered to offer excellent chemical resistance and durability while ensuring high filtration precision. Its smooth surface and superior breathability make it ideal for filtering powders and other particulate matter.

Vilene filter cloth is a high-performance filtration material designed for demanding industrial environments. Renowned for its alkali resistance, low elongation, and excellent moisture absorption, it is a preferred choice for filter presses handling alkaline materials. With durability 1-2x longer than pure cotton and a temperature limit of <100°C, it ensures cost-effective, long-term filtration solutions.

Technology and Manufacturing Process

Precision Weaving

Using computer-controlled looms, our production process guarantees uniform weave patterns and consistent quality across every batch. This precision ensures that each cloth meets the exact specifications required for optimal filtration.

High-Quality Materials

We source premium-grade fibers such as polypropylene and polyester that provide excellent chemical resistance, tensile strength, and durability. These materials are chosen based on rigorous performance standards to ensure they withstand the demands of industrial applications.

Innovative Coating Technologies

In some product lines, we apply specialized coatings that enhance the cloth’s resistance to clogging and improve its overall filtration performance. These coatings also contribute to easier cleaning and longer life cycles.

Quality Control and Testing

Every filter press cloth undergoes strict quality control measures and testing to ensure it meets international standards. Parameters such as mesh size, permeability, and mechanical strength are continuously monitored to guarantee reliability.

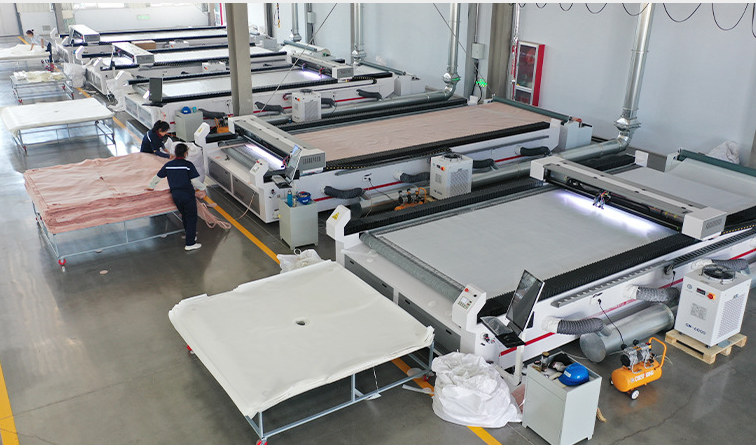

Precision Fabrication Technology

Why Loway cloths fit better and last longer.

- Laser-Cutting Technology (No Fraying)

We do not use hand scissors. All cloths are cut by automated laser machines based on CAD drawings. The laser instantly cauterizes (seals) the edges, preventing fiber fraying and ensuring dimension accuracy within ±1mm. - Calendering & Heat Setting (Dimensional Stability)

Before cutting, our raw fabric undergoes a hot calendering process. This “pre-shrinks” the material and smooths the surface.

- The Benefit: Your cloths won’t shrink drastically after the first week of use, and cake release is significantly improved.

- Specialized Neck & Edge Sealing

- Rubber Barrel Necks: For CGR plates, we weld flexible rubber necks that guarantee a watertight seal at the feed port.

- Latex Edge Coating: For critical applications, we apply a liquid latex coating to the sealing borders to prevent capillary leakage (wicking) entirely.

Advanced Filter Cloth Technologies

Surface Treatments and Finishes

Calendering

The process of pressing cloth through heated rollers to achieve a smoother surface.

- Benefits: Improved cake release, reduced cloth blinding, enhanced filtrate clarity

- Applications: Fine chemical processing, pharmaceuticals

Heat Setting

Thermal treatment to stabilize synthetic fibers and reduce shrinkage.

- Benefits: Improved dimensional stability, prolonged cloth life

- Applications: High-temperature filtration applications

Singeing

Controlled burning of surface fibers to create a smoother surface.

- Benefits: Reduced particle entrapment, better cake release

- Applications: Food processing, pharmaceutical production

Hydrophobic/Hydrophilic Treatments

Chemical treatments to modify the cloth’s interaction with water.

- Benefits: Tailored performance for specific applications

- Applications: Oil/water separation, specialty chemical processing

Edge Treatment Technologies

Heat-Sealed Edges

Thermal fusion of cloth edges to prevent fraying and leakage.

- Benefits: Extended cloth life, reduced contamination

- Applications: High-purity applications, food grade processing

Reinforced Edges

Additional material or stitching along cloth edges to enhance durability.

- Benefits: Increased mechanical strength, improved handling

- Applications: High-pressure applications, abrasive slurries

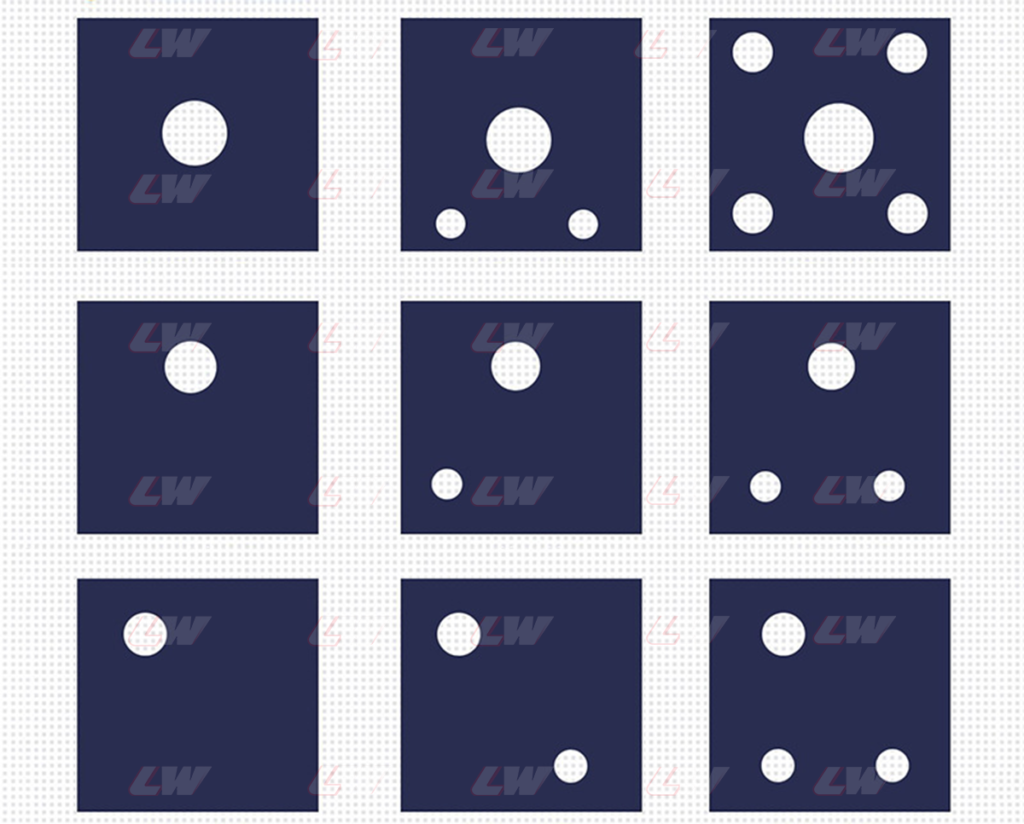

Grommeting and Custom Hole Patterns

Precision-placed metal or plastic reinforcements around mounting holes.

- Benefits: Proper alignment, reduced tearing at attachment points

- Applications: Custom filter press configurations, automated systems

Proven Solutions for Critical Industries

Mining Tailings(Coal, Gold, Copper)

Common Challenge: High Abrasion: Sharp particles wear out standard cloths quickly.

Recommended Solution: Nylon (PA66) Monofilament

Why This Works? Nylon offers superior abrasion resistance (3x better than PP). The smooth monofilament weave ensures fast drainage for massive volumes.

Chemical Pigments(TiO2, Dyestuffs)

Common Challenge: Particle Bleed-through: Ultra-fine particles pass through the cloth, causing cloudy filtrate.

Recommended Solution: PP Multifilament (Plain Weave)

Why This Works? The tight, twisted fiber structure captures particles as small as 1-5 microns, ensuring crystal-clear filtrate.

Metal Finishing (Electroplating)

Common Challenge: High Abrasion: Sharp particles wear out standard cloths quickly.

Recommended Solution: Nylon (PA66) Monofilament

Why This Works? Nylon offers superior abrasion resistance (3x better than PP). The smooth monofilament weave ensures fast drainage for massive volumes.

Food & Beverage(Sugar, Palm Oil)

Common Challenge: Hygiene & Temp: Must be food-safe and withstand hot filtration (>80°C).

Recommended Solution: FDA-Grade Virgin PP

Why This Works? Certified food-safe material. We use heat-sealed edges (no thread) to prevent fiber contamination in the food product.

Stone Cutting (Marble/Granite)

Common Challenge: Heavy Load: Heavy, dense cakes can tear the cloth neck.

Recommended Solution: Heavy-Duty PP with Rubber Neck

Why This Works? We reinforce the feed neck with a vulcanized rubber barrel, which absorbs the mechanical stress of heavy cakes.

At Loway Equipment, we’re committed to helping you optimize your processes with reliable and efficient filter press solutions.

Contact us today to learn more about how our filter presses can help improve your operations’ efficiency, productivity, and sustainability.

Frequently Asked Question

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How often should filter press cloths be replaced?

Replacement frequency varies significantly based on application, operating conditions, and maintenance practices. Typical lifespans range from 100-500 cycles for standard applications, while some specialty applications may require more frequent replacement. Establish a monitoring program that tracks performance metrics to determine the optimal replacement schedule for your specific operation.

Q2: How often should I clean my filter cloths, and what is the best method?

We recommend washing cloths every 15-20 cycles or whenever you notice filtration time increasing significantly.

- Method: Use a high-pressure water sprayer (50-80 bar). For chemical scaling (e.g., calcium carbonate), an Acid Wash (diluted HCl) may be required.

- Caution: Never use metal scrapers to clean cloths, as this will damage the fibers and cause immediate failure.

Q3: How do I know if I'm using the right filter cloth for my application?

The right cloth should provide acceptable filtrate clarity, reasonable cycle times, appropriate cake moisture content, and adequate service life. If you’re experiencing issues in any of these areas, it may indicate that your cloth selection could be optimized. Consider conducting a pilot test with alternative cloth types to compare performance.

Q4: What causes premature filter cloth failure?

Common causes include chemical incompatibility, excessive operating pressure, mechanical damage during handling, improper installation, inadequate cleaning, and abrasive wear from sharp particles. Identifying the specific failure mode through examination of used cloths can help determine the appropriate corrective action.

Q5: How can I improve cake release from my filter cloths?

Consider these approaches: (1) Select cloths with better release properties such as monofilament or membrane-coated varieties, (2) Ensure proper cloth tensioning during installation, (3) Optimize the final squeeze pressure and time in your cycle, (4) Evaluate whether a chemical additive to your slurry might improve release characteristics, (5) Consider surface treatments or finishes for your existing cloths.

Q6: How does temperature affect filter cloth performance?

Temperature impacts several aspects of cloth performance including dimensional stability, tensile strength, chemical resistance, and cake formation characteristics. Most synthetic filter cloths have specific maximum operating temperature limits beyond which permanent damage occurs. Additionally, higher temperatures may accelerate chemical degradation processes even when below the maximum temperature limit.

Q7: What is the relationship between cloth permeability and filtration performance?

Cloth permeability (measured in m³/m²/h or similar units) directly influences flow rate and pressure drop across the cloth. Higher permeability generally allows faster filtration but may reduce particle retention efficiency. The optimal permeability represents a balance between flow rate and filtration quality. As filtration progresses, cake formation becomes the primary flow resistance rather than the cloth itself.

Q8: How do I calculate the proper size and number of filter cloths needed for my filter press?

The calculation depends on your filter press dimensions and configuration. Measure your plate dimensions and count the number of chambers in your press. For standard recessed chamber presses, you’ll need one cloth per chamber plus one. Always verify measurements and consult with your filter press manufacturer for specific requirements for your equipment model.

Q9: How Can I Improve Filter Press Equipment Efficiency?

Efficiency improvement strategies:

Regular preventative maintenance

Proper cloth selection

Optimal pressure management

Consistent feed quality

Advanced automation

Periodic performance audits

Q10: What is blinding and how can it be prevented?

Blinding occurs when particles become embedded within or on the cloth structure, reducing permeability and flow rate. Prevention strategies include: (1) Selecting the appropriate cloth type for your particle characteristics, (2) Implementing regular and effective cleaning procedures, (3) Considering precoat filtration techniques, (4) Evaluating process modifications to change particle characteristics, and (5) Using surface-treated cloths with enhanced anti-blinding properties.

Q11: My filter cloths shrank after a few weeks of use. Is this normal?

Yes, slight shrinkage is normal for Polypropylene (PP) and Polyamide (PA) fabrics, especially in high-temperature environments.

- The Loway Solution: We anticipate this. Our cloths undergo a Pre-Shrinking (Heat Setting) process during manufacturing. Additionally, we size our cloths slightly larger (oversized by 1-2%) to accommodate residual shrinkage, ensuring they still fit the plate perfectly after the break-in period.

Q12: I am getting cloudy filtrate (dirty water). Is the cloth quality bad?

Not necessarily. Cloudy filtrate usually indicates:

- Incorrect Permeability: The cloth weave is too open (Air Permeability is too high). You may need a tighter Multifilament or Felt cloth.

- Start-up Phase: It is normal for the first few minutes of a cycle to be slightly cloudy until a “pre-coat” layer of cake forms on the cloth.

- Installation Issue: Check if the cloth neck is properly seated. A loose neck allows slurry to bypass the filtration chamber.

Q13: How do I prevent the filter cloth form leaking at the edges (Capillary Leakage)?

Capillary leakage (wicking) occurs when liquid travels through the fibers to the outside of the plate.

- Solution: Loway applies a specialized “Edge Coating” (Rubberized or Latex coating) to the sealing borders of the cloth. This blocks the fiber channels, creating a watertight barrier at the sealing face. Specify “Edge Coating” when ordering for messy or hazardous applications.

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Portable solutions for temporary sites

Dewatering Screw Press

Continuous operation for efficient sludge treatment