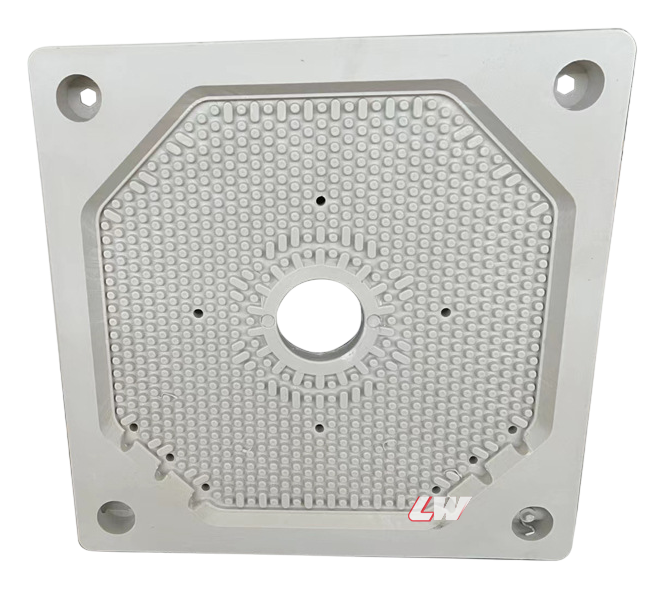

Reinforced Polypropylene Filter Plates

By combining the chemical stability of polypropylene with robust reinforcement materials, such as glass fiber, these filter plates deliver superior performance even under high-pressure and chemically aggressive environments. They are an ideal solution for industries including chemical processing, food and beverage, pharmaceuticals, and environmental protection.

Key Features & Benefits

✅Performance Advantages

- High pressure tolerance for efficient filtration cycles

- Uniform cake formation ensuring consistent product quality

- Excellent cake release reducing downtime between cycles

- Lower maintenance requirements than metal alternatives

- Reduced contamination risk from non-reactive materials

- Cost-effective operation through extended service life

✅Design Innovations

- Precision-engineered filtration channels for optimal flow distribution

- Reinforced feed eyes preventing distortion under pressure

- Enhanced corner design minimizing stress concentration

- Optimized drip edge for improved filtrate drainage

- Customizable port configurations to match specific process requirements

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Plate Size | 250mm × 250mm to 2000mm × 2000mm |

| Thickness | 15mm to 60mm |

| Chamber Depth | 15mm to 50mm |

| Working Pressure | Up to 16 bar (standard) / 25 bar (high-pressure) |

| Temperature Range | -10°C to 80°C (standard) / Up to 95°C (high-temp) |

| Feed Hole Diameter | 15mm to 80mm |

| Material | PP + 30% Glass Fiber (standard) |

| Surface Finish | Smooth or textured |

| Service Life | 3-5 years under normal operating conditions |

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Manufacturing Technology

Our reinforced polypropylene filter plates are produced using advanced injection molding technology, ensuring precise dimensional control and consistent quality.

Material preparation

Premium polypropylene resin is blended with precisely measured reinforcement materials

Injection molding

Computer-controlled molding ensures uniform material distribution

Controlled cooling

Optimized cooling cycles prevent internal stresses

Quality inspection

Rigorous testing for dimensional accuracy and structural integrity

Surface finishing

Specialized treatments to enhance cake release properties

Material Composition & Properties

Our reinforced polypropylene filter plates are engineered from premium-grade polypropylene resin fortified with glass fiber or other specialized reinforcement materials.

- Superior chemical resistance against acids, alkalis, and salts

- Enhanced mechanical strength for high-pressure applications

- Lightweight design compared to metal alternatives

- Extended service life in challenging industrial environments

- Temperature resistance for varied processing conditions

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How long do reinforced polypropylene filter plates typically last?

Under normal operating conditions, these plates have a service life of 3-5 years. However, this can vary based on operating pressure, chemical exposure, temperature conditions, and maintenance practices.

Q2: Can reinforced polypropylene filter plates withstand high temperatures?

Standard reinforced polypropylene plates can operate reliably up to 80°C. For higher temperature applications up to 95°C, specially formulated high-temperature grades are available.

Q3: How do I know when filter plates need replacement?

Signs that indicate replacement may be necessary include visible cracks or deformation, decreased filtration efficiency, inconsistent cake formation, and leakage between plates during operation.

Q4: Can reinforced polypropylene filter plates handle abrasive materials?

Yes, the glass fiber reinforcement significantly improves abrasion resistance compared to standard polypropylene plates, making them suitable for moderately abrasive slurries.

Q5: Customization Options

Our engineering team can develop custom solutions to meet your specific filtration requirements:

- Custom sizes to fit existing filter press equipment

- Specialized port configurations for unique process flows

- Variable chamber depths for different cake thickness requirements

- Enhanced reinforcement options for extremely demanding applications

- Surface texture modifications for specialized cake release properties

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.