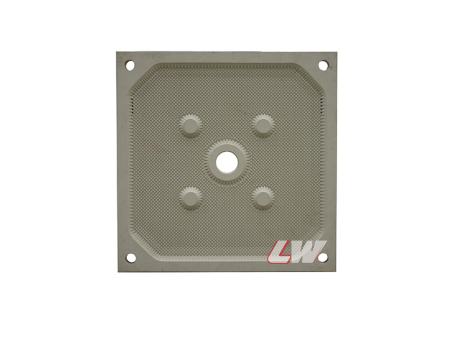

Intermediate Feed Membrane Filter Plates

Intermediate feed membrane filter plates are critical components in industrial filtration systems, designed to optimize solid-liquid separation processes. Their unique center-feed design and advanced membrane technology ensure high efficiency, durability, and versatility across industries like chemical processing, food and beverage, pharmaceuticals, and wastewater treatment.

Key Features

✅Center Feed Design: Liquid enters through the central inlet port, promoting uniform distribution and reducing localized pressure on the filter media

✅Membrane Structure: Features an elastic membrane typically made of rubber or similar flexible materials that deforms under pressure to enhance solid-liquid separation

✅Reinforced Framework: Equipped with a strengthened frame to provide additional structural integrity and stability during operation

✅Durable Construction: Manufactured using corrosion-resistant materials to withstand harsh industrial environments

✅Easy Maintenance: Designed for simple disassembly and cleaning, reducing downtime and maintenance costs

Technical Specifications

| Parameter | Details |

|---|---|

| Material Options | Membrane: NBR, EPDM, FKM; Frame: Stainless Steel 304/316, PP, Cast Iron |

| Operating Pressure | 7–16 bar (adjustable based on application) |

| Temperature Range | -20°C to 150°C (depending on membrane material) |

| Filtration Area | Customizable (standard sizes: 800×800 mm to 1500×1500 mm) |

| Applications | Chemical slurries, wastewater sludge, food-grade liquids, pharmaceuticals |

Technology & Material Selection

Membrane Materials

- Chemical & Heat Resistance: Our membranes are typically crafted from materials such as natural rubber or nitrile rubber, chosen for their ability to resist chemical corrosion and high temperatures.

Frame Materials

- Durability & Corrosion Resistance: Frames are manufactured using high-grade stainless steel or other robust, corrosion-resistant materials, ensuring long-lasting performance even in demanding environments.

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Advantages

High Efficiency

Membrane pressing significantly increases the dewatering rate of solid particles

Uniform Distribution

Even distribution of liquid across the filter media reduces localized wear

Improved Cake Discharge

Enhanced design facilitates easier cake release after filtration

Extended Service Life

Quality materials and structural design ensure durability and reliability

Versatility

Suitable for various applications across multiple industries

Resource Conservation

Efficient solid-liquid separation contributes to water and material conservation

Technology Innovations

- Smart Monitoring Systems: Integration of pressure and flow sensors for real-time performance monitoring.

- Advanced Membrane Materials: Development of membranes with enhanced chemical resistance and longer service life.

- Optimized Flow Channels: Redesigned internal channels for improved liquid distribution and reduced pressure drop.

- Heat Setting & Finishing: Improves dimensional stability and enhances mechanical properties.

- Energy-Efficient Designs: Structural improvements that reduce energy consumption during the filtration process.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How do these filter plates improve filtration efficiency?

The central feed ensures even liquid distribution, while the pressure-induced membrane deformation squeezes the filter cake to release more liquid, thereby increasing the dewatering rate.

Q2: What materials are used in these filter plates? A:

The membranes are generally made from high-quality, chemically-resistant rubber (such as natural or nitrile rubber), and the frames are constructed from stainless steel or other corrosion-resistant materials.

Q3: How often should membrane filter plates be replaced?

The replacement frequency depends on operating conditions, but typically ranges from 1-3 years. Regular inspection for signs of wear, tears, or deformation is recommended to determine when replacement is necessary.

Q4: Can membrane filter plates handle high-temperature applications?

Yes, with appropriate membrane materials. EPDM rubber membranes can typically handle temperatures up to 120°C, while specialized high-temperature membranes can operate at even higher temperatures.

Q5: In which industries are these filter plates most commonly used?

They are widely used in the chemical, food and beverage, pharmaceutical, and environmental protection industries, among others.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.