Our Service

Your Trusted Partner in Industrial Filtration

Advanced Filtration Technology for Maximum Efficiency

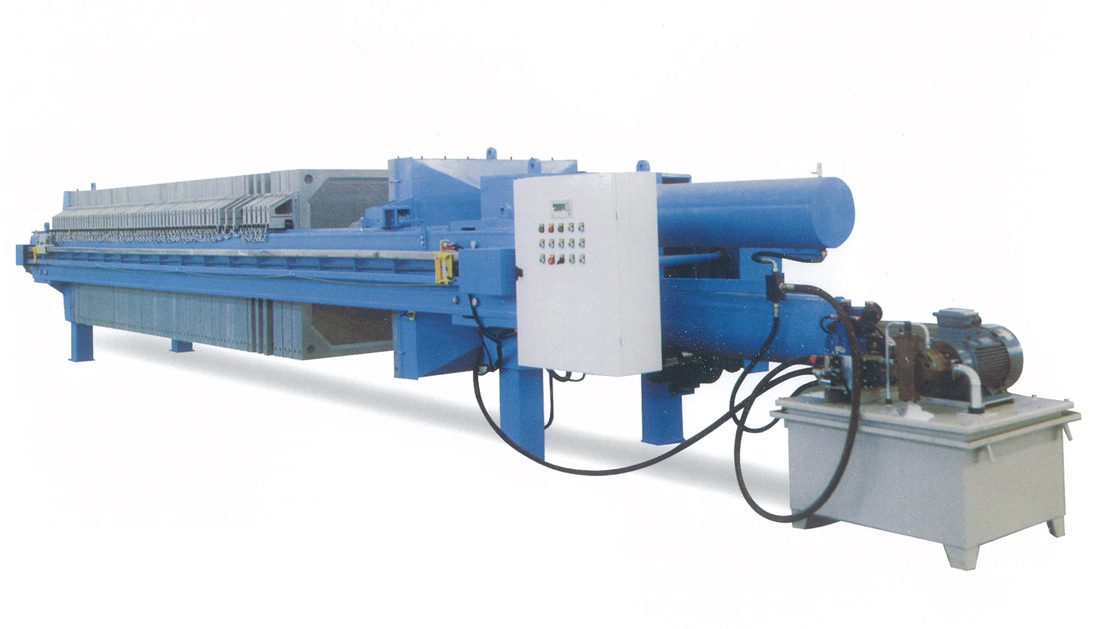

For over two decades, Loway Equipment has been at the forefront of industrial filtration solutions. Our high-performance filter presses deliver superior solid-liquid separation across multiple industries, helping businesses optimize their processes while reducing operational costs and environmental impact.

Industries We Serve

- Mining & Minerals: Tailings dewatering, concentrate filtration

- Chemical Processing: Chemical recovery, product purification

- Food & Beverage: Juice clarification, oil filtration

- Pharmaceutical: API production, high-purity filtration

- Wastewater Treatment: Sludge dewatering, water reclamation

- Metal Processing: Metal hydroxide filtration, coolant recycling

- Ceramics: Clay processing, glaze preparation

86 189 5282 5752

Our Key Filter Press Services

Custom Design & Engineering

Our experienced engineers work closely with your team to design filter press systems that perfectly match your operational requirements.

- Material characteristics

- Production volume

- Space limitations

- Budget constraints

- Environmental regulations

Installation & Commissioning

Our certified technicians ensure your filter press system

- Properly installed according to specifications

- Integrated with existing processes

- Optimized for peak performance

- Fully tested before handover

Spare Parts & Components

We maintain extensive inventory of genuine Loway parts

- Filter cloths and plates

- Hydraulic components

- Control system parts

- Pumps and valves

- Seals and gaskets

Comprehensive Maintenance Programs

Our certified technicians ensure your filter press system

- Properly installed according to specifications

- Integrated with existing processes

- Optimized for peak performance

- Fully tested before handover

Operator Training

Ensure your team has the knowledge to operate your filter press effectively

- Hands-on training sessions

- Operational best practices

- Troubleshooting procedures

- Safety protocols

- List Item

- Basic maintenance procedures

Advanced Filter Press Technology

Innovative Plate Design

Our proprietary plate design maximizes filtration area while ensuring: Uniform pressure distribution, Effective cake release, Reduced cloth wear, Optimized filtration cycles.

Smart Control Systems

Our PLC-based control systems provide: Real-time performance monitoring, Automated cycle optimization, Remote operation capabilities, Data logging for process analysis, Predictive maintenance alerts.

High-Pressure Hydraulics

Our industrial-grade hydraulic systems deliver: Consistent closing pressure, Rapid cycle times, Energy-efficient operation, Long-term reliability, Low maintenance requirements.

Contact Loway Equipment Today

Ready to optimize your filtration process? Contact our team of filtration experts for a consultation and customized solution proposal.

Why Choose us

Industry Expertise: Our team is highly skilled in designing and manufacturing filtration solutions for various industries, ensuring that you receive the best products for your needs.

Cutting-Edge Technology: We use the latest advancements in filtration technology to deliver high-performing, durable systems.

Global Customer Base: From small businesses to large enterprises, we provide filtration solutions for companies all around the world.

We are proactive in ensuring that our supply chain can supply the high-quality materials needed for us to perform at the highest levels to meet our customers’ requirements.

We continuously invest in research and development, pushing the boundaries of filtration technology.

Our technologies are designed to minimize environmental impact and maximize operational efficiency.

Striving for the highest standards in design, engineering, and manufacturing.

Every product undergoes rigorous testing and meets international manufacturing standards.

We view each client partnership as a collaborative journey of technological advancement.

Promoting environmentally friendly solutions through energy-efficient filtration systems.

Building long-term relationships by understanding and meeting customer needs.

Rapid response team for emergencies, spare parts, and process optimization.

-

What is a filter press and how does it work? 1

A filter press is a solid-liquid separation device that uses pressure to force a slurry through filter cloths, capturing solids as a "cake" while allowing filtered liquid to pass through. The process involves filling chambers with slurry, applying pressure, filtering, and finally releasing the solid cake.

-

How do I choose the right filter press size? 2

The appropriate filter press size depends on your throughput requirements, available space, and material characteristics. Our engineers can help determine the optimal size based on: Daily processing volume Desired cycle time Solids concentration in feed Required cake dryness Available floor space

-

What maintenance does a filter press require? 3

Regular maintenance includes: Filter cloth inspection and replacement Hydraulic system checks Plate inspection for damage Seal and gasket examination Control system updates Lubrication of moving parts Most Loway filter presses require comprehensive maintenance every 3-6 months depending on usage.

-

How long do filter cloths last? 4

ilter cloth lifespan varies based on application, material type, and operating conditions. Typically, cloths last between 3-12 months. Factors affecting lifespan include: What types of materials can be processed with a filter press? Filter presses can process a wide range of slurries including: Metal hydroxide precipitates Mineral slurries Chemical products Food processing waste Municipal and industrial sludges Ceramic slips Pigments and dyes

-

What types of materials can be processed with a filter press? 5

Filter presses can process a wide range of slurries including: Metal hydroxide precipitates, Mineral slurries, Chemical products, Food processing waste, Municipal and industrial sludges, Ceramic slips, Pigments and dyes.

-

How automated can a filter press system be? 6

Modern filter press systems can be highly automated, from basic semi-automatic operation to fully automatic systems with: Automatic plate shifting, Remote monitoring and control, Self-adjusting pressure profiles, Automatic cloth washing, Cake discharge automation, Integration with plant control systems.

-

Can your filter presses be customized? 7

Absolutely. We offer fully customizable solutions to meet unique operational requirements. From plate materials to system automation, we can modify the design to match your specific process and environmental conditions.

-

How can I request a consultation or get a quote? 8

Simply reach out to our customer service team via our website or call our dedicated support line. We’ll provide a comprehensive consultation and detailed quote based on your unique needs.

Our Key Filter Press Services

+ 68 cooperation countries

+ 98.5% successful projects

Our customers consistently praise our products and services, sharing positive feedback about their excellent performance and reliability.