Loway Belt Filter Press: Advanced Industrial Sludge Dewatering Solutions

Fully Automated Filter Press System | Continuous Dewatering Filtration Solutions

Loway Equipment is a premier belt filter press manufacturer in China, specializing in high-performance industrial solid-liquid separation. Our automatic belt filter press technology is engineered for maximum efficiency in belt press dewatering, reliably handling high-volume municipal and industrial sludge.

As experts in sludge dewatering belt press design, we deliver robust, customized belt press filter solutions that reduce operational costs and ensure compliance with regulations.

Each industrial belt filter press integrated advanced belt press dewatering technology with PLC automation, ensuring reliable performance in wastewater treatment plants, chemical facilities, and environmental projects worldwide.

Key advantages

Ideal for wastewater treatment belt press applications in chemical, petrochemical, pharmaceutical, food & beverage, pulp & paper, mining, and environmental remediation.

- Continuous Operation:

Unlike batch systems, the belt press runs 24/7 with stable throughput—ideal for plants with fluctuating sludge loads.

- Energy Efficiency:

Moderate power consumption (15–45 kW) combined with optimized flocculant dosing reduces overall operating costs.

- High Cake Solids:

Achieves 18–30% dry solids under typical conditions; specialty designs exceed 35% for challenging sludges.

- Scalable Capacity:

Models range from 5 m³/h to 150 m³/h (sludge flow), accommodating small municipal plants to large industrial complexes.

- Eco-Friendly:

Minimizes landfill volume, lowers transportation emissions, and recovers water for reuse—supporting circular economy goals.

Loway Belt Filter Press Models

We engineer a range of belt press filters to meet specific dewatering challenges. While the standard model is highly effective for general municipal and industrial sludge, specialized applications demand advanced pressure mechanisms.

Product type | Function | Key benefit | Application | Know more |

Standard belt filer pressLWBFP | Gravity+ low/medium pressure | Achieve 18-25%cake solids, moderate energy consumption (15-30KW) | General municipal and industrial sludge dewatering | |

High pressure belt filter pressLWHBFP | Upgrade hydraulic systems, increase roller compression | Achieve 25-35% cake dryness | Downstream drying or incineration efficiency depends on maximum moisture removal | |

Vacuum belt filter pressLWVBFP | Negative pressure suction | Superior filtration on fine particles and low-concentration feeds | Mining tailings, mineral processing, specialized chemical applications |

How Belt Press Dewatering Works

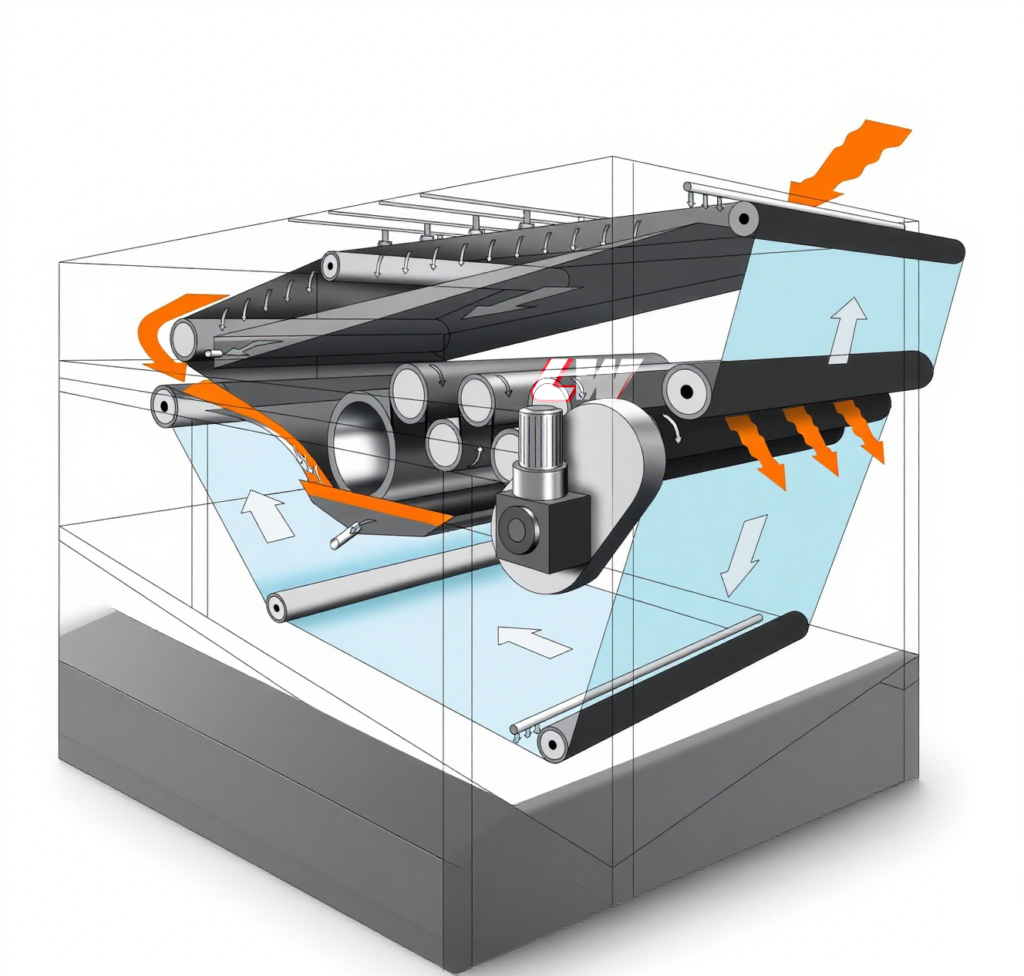

The principle of our sludge dewatering belt press combines chemical conditioning, gravity drainage, and progressive mechanical compression in 5 synchronized stages:

- Sludge Conditioning& Flocculation: Raw sludge is pumped into a flocculation tank where it is mixed with a liquid polymer. This chemical process causes small particles to bind together, forming large, robust flocs.

- Gravity Drainage Zone: The conditioned sludge is distributed onto the filter belt, where free water drains rapidly by gravity.

- Wedge Pre-Compression Zone: Upper and lower belts converge at an adjustable wedge black, applying gentle squeeze pressure. This pre-compression stage expels more free water and prepares the sludge for high-pressure dewatering.

- High-Pressure Roller Compression: The sludge cake passes through 4-7 sequential compression rollers with decreasing diameters in an S-shaped path. Hydraulic or pneumatic cylinders maintain precise pressure, forcing bound water through both blet layers.

- Cake Discharge & Belt Cleaning: Doctor blades scrape dewatered cake onto discharge conveyors. High-pressure spray nozzles clean the filter belts before they re-enter the conditioning zone, ensuring continuous, clog-free operation.

Core Engineering & Key Components

The reliability of a belt filter press is in its components. We over-engineer our systems for maximum uptime.

- High-Performance Filter Belts: Premium polyester (PET) monofilament belts with superior drainage, chemical resistance, and tensile strength.

- Precision Roller System: All rollers are dynamically balanced and rubber-coated (or stainless steel) for excellent grip and corrosion resistance.

- Automated Belt Tensioning: Pneumatic systems automatically maintain optiomal belt tension, extending belt life and preventing misalignment.

- Reliable Belt Tracking: Pneumatic tracking system constantly monitors belt position and makes micro-adjustments, preventing belt damage and ensuring process stability.

- Advanced Polymer Dosing: Our automated polymer systems ensure precise chemical preparation and dosing, reducing waste and maximizing flocculation efficiency.

- Intuitive PLC Touchscreen Panel: HMI central control panel allows for easy adjustment of all parameters, recipe storage, and integration with your central SCADA system.

Technical Parameters

| Loway Belt filter press and thickener integrated machine | ||||||

| Model | Feed moisture content | Belt width | Capacity | Power | Speed | External dimensions |

| LWSW1000 | 97-99% | 1000 mm | 10-15 m³/h | 3.75 kw | 1-12 m/min | 5.5*1.55*2.3 m |

| LWSW1500 | 97-99% | 1500 mm | 15-20 m³/h | 5.5 kw | 1-12 m/min | 5.5*1.55*2.3 m |

| LWSW2000 | 97-99% | 2000 mm | 20-30 m³/h | 7 kw | 1-12m/min | 5.5*1.55*2.3 m |

| Model | Feed moisture content | Belt width | Capacity | Power | Speed | External dimensions |

| LWDY2000/12-SA | 97-99% | 2000 mm | 30-40 m³/h | 4+1.1 kw | 1-12 m/min | 12*2.6*2.5 m |

| LWDY2500/12-SA | 97-99% | 2500 mm | 30-50 m³/h | 5.5+1.5 kw | 1-12 m/min | 12*3.1*2.5 m |

| LWDY3000/12-SA | 97-99% | 3000 mm | 50-80 m³/h | 7.5+3 kw | 1-12 m/min | 12*3.6*2.5 m |

| LWDY3500/14-SA | 97-99% | 3000 mm | 70-100 m³/h | 7.5+4 kw | 1-12 m/min | 14*3.6*2.5 m |

Performance Range:

Feed sludge concentration: 0.5-5% solids

Cake moisture content: 65-80% (varies by sludge type)

Hydraulic loading: 12-26 m³/h per meter belt width

Belt speed: 1.2-15 m/min (variable by zone)

Advantages of Loway Belt Filter Press Technology

Choosing the right belt press filter directly impacts your operational costs and efficiency. Our solutions are engineered to deliver measurable benefits:

Continuous 24/7 Operation: Unlike batch systems, our automatic belt filter press runs 24/7 without interruption, providing stable throughput ideal for plants with fluctuating sludge generation rates.

High Cake Solids: Our precision-engineered roller configuration and optimized flocculation system achieve high cake dryness, typically ranging from 18% to 35% solids (sludge-dependent), significantly reducing disposal volume and transport costs.

Durable & Robust Construction: Built with high-grade 304/316 Stainless Steel or heavy-duty coated carbon steel, our machines are designed for low maintenance and a long service life in harsh industrial environments.

Fully Automated System: Equipped with PLC-controlled system, our presses manage belt speed, tension, tracking, and washing cycles automatically. This ensures consistent performance.

High Energy Efficiency: Moderate power consumption 15-45kW combined with optimized polymer dosing delivers low operating costs per cubic meter of sludge processed. Gravity drainage handles initial dewatering without mechanical energy input.

Belt filter press Manufacturer- Loway Production Capabilities

As a leading belt filter press manufacturer in China, Loway Equipment operates a state-of-the-art manufacturing facility dedicated to dewatering equipment production. Our vertical integration- from raw material procurement through final assembly and testing-ensures quality control at every stage while delivering competitive pricing without compromising performance.

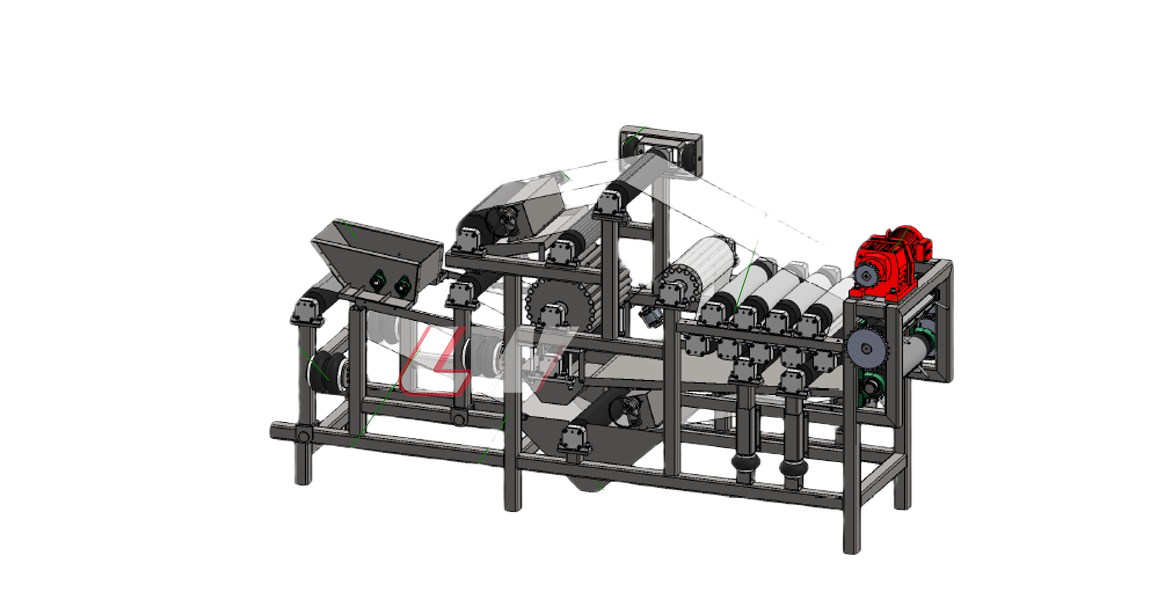

Loway Fabrication Capabilities: Our production floor houses CNC machining centers, laser cutting systems, automated welding stations, and precision rolling equipment. These advanced manufacturing infrastructures enable us to manufacture belt filter press frames, roller assemblies, and structural components to tolerances within ±0.5mm, critical for belt tracking stability and long-term reliability.

Loway Belt Filter Press Manufacturing Process

- Engineering & Design: Our process starts with your sludge data. We use 3D modeling and process calculations to design a system optimized for your specific application, capacity, and dryness requirements.

- Frame Fabrication & Coating: We use high-grade Q235 or stainless steel (ss304/316), precision-cut and robotically welded for perfect alignment. All carbon steel frames undergo multi-stage sandblasting and heavy-duty epoxy coating for maximum corrosion resistance.

- Precision Assembly: Our skilled technicians install high-quality rollers, sealed bearings, and PLC and HMI control systems sourced from word-class suppliers (Siemens, Schneider, ABB).

- Factory Acceptance Testing (FAT): The complete unit undergoes rigorous testing, simulating real-world operating conditions to ensure all technical parameters are met before shipment.

Customized Blet Filter Press Solutions

Loway recognizes that standardized equipment rarely addresses every application challenge. Our customized solution service includes on-site sludge testing, tailored chemical dosing recommendations, and post-installation support, ensuring your belt press dewatering system performs optimally from day one.

Sludge Lab Testing

We test your sludge sample in our lab to determine the optimal polymer type, dosing, and machine configuration to project your achievable cake dryness percentage.

Material & Component Selection

Choose from coated carbon steel or 304/316 stainless steel. Select specific belt weaves from your particle size.

Full System Integration

We design the complete belt press dewatering skid. This includes the sludge feed pumps, polymer doing units, air compressors, and cake discharge conveyors for a true turnkey solution.

Turnkey Solutions: Loway can provide complete sludge management systems integrating multiple technologies for optimal performance.

Belt Filter Press Applications

Our industrial belt filter press systems are proven in the most demanding environments

Municipal Wastewater Treatment

Sludge dewatering belt press systems serve a primary dewatering equipment in sewage treatment plants. These machines process activated sludge, primary clarifier sludge, and anaerobically digested biosolids, reducing volume 75-85% for landfill disposal or beneficial reuse as soil amendments.

Industrial Process Wastewater

Chemical manufacturing, pharmaceutical production, petrochemical refineries, and food processing facilities rely on industrial belt filter press technology for:

Biological treatment sludge dewatering

Chemical precipitation sludge handling

Oil sludge separation and recovery

Protein and fiber recovery from process streams

Mining & Mineral Processing

Tailing dewatering, coal slurry processing, and mineral concentrate thickening applications benefit from continuous belt press dewatering capacity, enabling water recycling and reducing environmental liability.

Pulp & Paper Industry

Paper mill sludge (de-inking, primary, and biological) requires reliable dewatering before disposal or energy recovery through incineration. Our automatic belt filter press systems maintain consistent performance despite fiber content variations.

Frequently Asked Questions (FAQ)

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is the typical capacity of belt filter press?

Belt filter press capacity depends primarily on belt width and sludge characteristics. Standard models range from 5 m³/h (500mm belt width) to over 150m³/h (more than 3000mm belt) for large-scale industrial units. For precise capacity calculation, we require jar test data including feeding solids percentage, polymer type, dosage rate, and target cake consistency. Contact our engineering team with your specific parameters for customized sizing recommendations.

Q2: How is a belt filter press used for wastewater treatment?

In wastewater treatment, a belt filter press is a critical solid-liquid separation device used in the final dewatering stage. It tanks thickened sludge (the semi-solid byproduct of biological or chemical treatment), conditions it with a polymer, and presses it between two porous belts. This process efficiently separates the remaining water (filtrate) from the solids, creating a dry “cake” that is significantly lighter and cheaper to transport and dispose of.

Q3: What maintenance does a belt filter press require?

Proper belt filter press maintenance is key to longevity and performance, which follows a structured preventive schedule to ensure reliable operation:

Daily: Check spray nozzles for clogs, monitor belt tracking and tension, clean doctor blades, inspect polymer dosing system, check wash water pressure (≥0.5 MPa).

Week: Lubricate bearings (per OEM specifications), examine belts for damage, test hydraulic/pneumatic systems.

Monthly: Deep-clean spray nozzles, inspect drive chains and tensioners, calibrate sensors, analyze cake samples.

Periodic: Inspect belts for wear or damage and perform a chemical cleaning (acid/ alkali wash) of the belts if they become “blinded” by inorganic scale or biological growth.

Q4: What is common belt filter press troubleshooting?

Common belt filter press troubleshooting issues include:

- Poor Cake Dryness: often caused by improper polymer dosing (too much or too little), incorrect belt speed (too fast), or low belt tension.

- Belt “Blinding”: The belt pores clog with fines or grease. This is fixed by checking and cleaning the high-pressure spray nozzles or performing a chemical wash.

3. Belt Misalignment: This triggers the automatic tracking system. It it persists, check the tensioning system, roller alignment, or look for uneven sludge loading.

Q5: Can belt filter press handle varying feed conditions?

Modern belt filter press systems incorporate adaptive control technologies that automatically adjust operational parameters to accommodate varying feed conditions. However, significant changes in feed characteristics may require polymer dosage adjustments or operational modifications.

Q6: What cake dryness percentage can belt filter presses achieve?

Belt filter press cake dryness percentage can varies by sludge type and system configuration. As a general guide:

Municipal Activated Sludge: 18%-30% solids

Digested Municipal Sludge: 20%-30% solids

Paper Mill Sludge: 25%-35% solids

Mining Tailings: 40%+ solids

As your manufacturing partner, we highly recommend our customized solution service, which includes lab testing your sludge to provide an accurate projection before you buy.

Q7: Can the system be automated?

Yes, modern belt filter press systems feature comprehensive automation including automatic startup/shutdown sequences, adaptive process control, remote monitoring capabilities, and integrated maintenance scheduling systems. These automated features reduce labor requirements while optimizing performance consistency.

Get Your Custom Belt Filter Press Solution Today

The Loway Equipment team is ready to design an industrial belt filter press system that matches your exact requirements.

Contact our filtration experts today for a technical consultation, a free quote, or to schedule a sludge test.

Related Products

Rotary Drum Filter

High-efficiency microfilter machines for solid-liquid separation

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Portable solutions for temporary sites

Dewatering Screw Press

Continuous operation for efficient sludge treatment