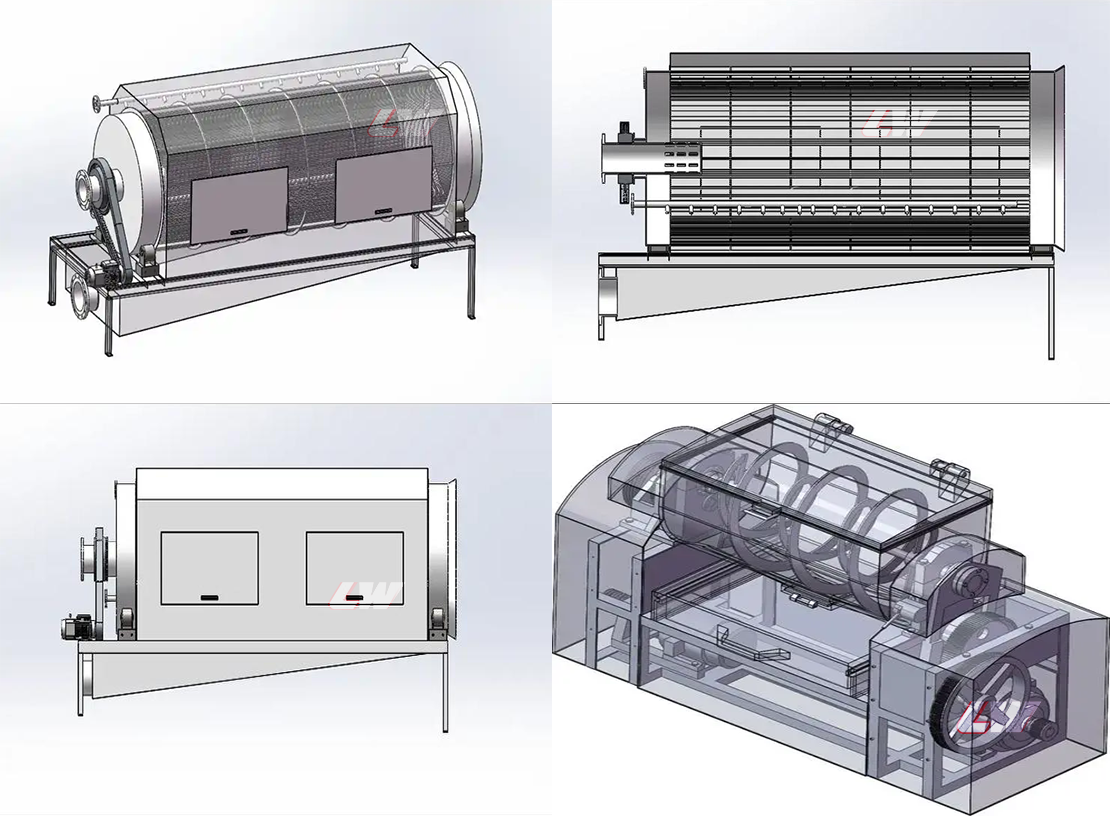

Industrial Rotary Drum Filter

High-efficiency microfilter machines for solid-liquid separation. Rotary drum filters for water treatment, wastewater processing, and industrial applications.

Loway Rotary Drum Filters

Loway Equipment is a trusted global rotary drum filter manufacturer and supplier specializing in high-capacity, self-cleaning Rotary Drum Filters (RDF). Engineered for continuous operation and minimal maintenance, our RDF systems provide superior solid-liquid separation for critical applications in municipal wastewater treatment, industrial processing, and intensive aquaculture (RAS). We deliver ISO-grade fabrication and custom rotary drum filter solutions to meet your exact flow and filtration specifications.

Engineered for Reliability: Why Choose Loway as Your Rotary Drum Filter Manufacturer?

We design our industrial rotary drum filters to solve the most common challenges faced by engineers and plant managers: operational downtime, high maintenance costs, and inconsistent filtration quality.

Get Your Custom Filtration Solution & Rotary Drum Filter Price

• 304/316L stainless steel construction

• Custom high-capacity designs 10-500 m³/h

• ISO 9001 certified

• Micron-level fine filtration

Feature | Description |

Automated Self-Cleaning System | Features a continuous, high-pressure backwash system that automatically cleans the rotary drum screen without manual intervention, ensuring uninterrupted flow and optimal performance. High-pressure spray nozzles (3-6 bar) remove captured solids during drum rotation, maintaining 90-95% filtration efficiency throughout operation. Typical cleaning cycle: 2-5 minutes per rotation. |

High-Capacity Design | Modular and scalable systems engineered to handle high flow rates, with capacities ranging from 50 m³/h up to 500 m³/h per unit. This makes us a leader in high-capacity rotary drum filter solutions. |

Precision Filtration | We offer a range of filter mesh sizes, with minimum filtration ratings as low as 10 microns, capture suspended solids with 85-95% removal efficiency and particulate matter. Our precision mesh installation system ensures uniform tension across the entire drum surface, maintaining flatness within 2mm for optimal filtration performance. |

Durable, Corrosion-Resistant Build | Standard 304 stainless steel or optional 316L stainless steel materials provide superior corrosion resistance for harsh industrial environments. All structural components undergo precision CNC fabrication for dimensional accuracy within ±0.5mm tolerances. |

Low Total Cost of Ownership (TCO) | Gravity-driven operation minimizes energy consumption, total power consumption typically 0.37-2.2 kW depending on capacity – up to 70% less energy than equivalent vacuum drum filters. Simple, robust design with easily replaceable, modular rotary drum filter parts minimizes maintenance frequency and labor costs. |

Fully Customizable Solutions | Our engineering team provides application-specific custom rotary drum filter design services including inlet/outlet configurations, materials of construction, automation level, and integration with existing systems. |

Applications Across Industries

The Loway rotary drum screens is a versatile pre-treatment and tertiary filtration solution. We provide application-specific engineering to ensure compliance and efficiency in your sector.

• Municipal and Industrial Rotary Drum Filter for Wastewater Treatment.

• Ideal for primary clarification in municipal and industrial wastewater treatment plants. Our filters effectively remove Total Suspended Solids (TSS) and are a reliable solution for sludge dewatering pre-treatment, reducing the load on downstream equipment.

• Rotary Drum Filter for Aquaculture and Recirculating Aquaculture Systems (RAS).

• The core filtration component for Recirculating Aquaculture Systems (RAS). Our aquaculture drum filters efficiently remove solid waste (fish feces, uneaten feed) to maintain superior water quality, protect fish health, and increase stocking density.

• Food Processing Rotary Drum Filter and Product Recovery.

• Content: Used for solid-liquid separation in processes such as meat processing, brewery mash filtration, fruit juice clarification, and vegetable washing. Our systems help recover valuable byproducts and reduce wastewater surcharges.

We also engineer systems for other industrial uses, including:

- Pulp & Paper

- Textile Industry

- Chemical Industry (for specific non-vacuum applications)

- Lithium Battery Production (material recovery)

- Mining (for tailing water, not RDVF applications)

Rotary Drum Filter Working Principle & Design Specification

How It Works: The Continuous Filtration Cycle

Our filters operate on a straight forward principle combining mechanical screening with automated cleaning:

Step 1: Feed Entry: Wastewater or process liquid enters the filter housing and flows toward the rotating drum via gravity or low-pressure pumping. Internal flow distribution baffles ensure uniform liquid approach across the drum length.

Step 2: Solid-Liquid Separation: As liquid passes through the drum’s fine mesh screen (20-500 microns), suspended solids are retained on the exterior surface while filtered water flows into the drum interior. The rotary drum filter working principle relies on differential pressure across the screen to drive filtration.

Step 3: Cake Formation & Rotation: Captured solids accumulate on the mesh surface, forming a filtration “cake” that actually enhances particle capture efficiency. The drum continuously rotates at 1-8 RPM, carrying the captured material to the cleaning zone.

Step 4: Self-Cleaning Cycle: When the drum section rotates to the top position, high-pressure spray nozzles (3-6 bar) activate automatically, washing captured solids into an internal collection trough. The self-cleaning process takes 5-15 seconds per drum section, ensuring uninterrupted filtration.

Step 5: Filtered Water Discharge: Cleaned water exits through the drum’s internal manifold system to down stream processes or final discharge. Level sensors control inflow to maintain optimal submergence depth (typically 60-80% of drum diameter).

Technical Specifications

Loway Equipment’s Rotary drum filters have multiple series models, and the parameter differences of different models can meet the personalized needs of different scenarios. Specific parameters are as follows:

| Model | Filter Area (m²) | Capacity (T/H) | Drum Diameter (mm) | Motor Power (KW) | Applications |

|---|---|---|---|---|---|

| LWRD1 | 5 | 50-100 | Ф960 | 1.1 | Small-scale operations |

| LWRD2 | 7 | 80-150 | Ф1250 | 1.1 | Medium facilities |

| LWRD3 | 9 | 100-200 | Ф1250 | 2.2 | Industrial processing |

| LWRD4 | 11 | 120-240 | Ф1500 | 2.2 | Large-scale treatment |

| LWRD5 | 14 | 150-300 | Ф1500 | 3.0 | Heavy-duty applications |

| LWRD6 | 16 | 170-350 | Φ1500 | 4.0 | Municipal systems |

| LWRD7 | 24 | 220-400 | Φ1780 | 5.5 | High-capacity plants |

| LWRD8 | 30 | 300-500 | Φ1780 | 7.5 | Maximum throughput |

Optional Features & Upgrades:

✓ UV-resistant polycarbonate housing for outdoor installation

✓ 316L stainless steel upgrade for marine/corrosive environments

✓ Explosion-proof motors and controls (ATEX/IECEx Zone 1/2)

✓ Ultra-fine mesh screens (20-40 microns for aquaculture)

✓ Heated enclosure with insulation (-20°C to -30°C operation)

✓ Turbidity meter and automatic backwash triggering

✓ Multiple drum configuration (2-3 drums in series/parallel)

✓ Mobile skid-mounted design with wheels

✓ Stainless steel solids collection cart

Loway: Your Trusted Global Rotary Drum Filter Manufacturer and Supplier

We believe trust is built on transparency. Loway Equipment is an ISO-certified rotary drum filter manufacturer, controlling the entire process from engineering design to final testing. We are proud to be a leading rotary drum filter supplier in Asia.

The Loway 6-Step Quality Assurance Process

- 1. Design Optimization: Experienced engineers use CFD modeling to validate custom rotary drum filter designs.

- 2. Precision Fabrication: All components are cut and formed using CNC machinery from certified stainless steel rotary drum filter materials.

- 3. Automated Welding: Core drums and frames are constructed using automated welding techniques to guarantee weld integrity.

- 4. Mesh Integration: Proprietary techniques are used to precisely integrate the rotary drum screen to withstand high-pressure backwash.

- 5. System Integration: High-quality motors and controls are integrated and pre-tested for stable, fully automatic operation.

- 6. Rigorous Factory Acceptance Test (FAT): Every unit undergoes a mandatory 48-hour continuous load test before shipment.

Ready to Optimize Your Filtration Process?

Whether you are managing municipal effluent, upgrading your RAS facility, or seeking reliable industrial solid-liquid separation, our engineering team is ready to provide a proven, cost-effective solution.

Frequently Asked Questions (FAQ)

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is the rotary drum filter price?

Pricing is determined by the required capacity (m³/h), filtration rating (micron), and material (SS304/316L). Please use the form above to request a custom quote and technical proposal.

Q2: How does a rotary drum filter work?

A rotary drum filter is a continuous solid-liquid separation device consisting of a cylindrical drum covered with fine mesh screening. The drum rotates partially submerged in wastewater, and as liquid flows through the mesh by gravity, suspended solids are captured on the exterior surface. An automated high-pressure spray system periodically cleans the mesh, washing collected solids into a discharge trough.

The complete working principle involves five steps: feed entry → filtration through rotating mesh → cake formation → automatic backwash cleaning → filtered water discharge. This self-cleaning

process maintains consistent filtration efficiency without operator intervention.

Q3: How We Compare: Rotary Drum Filter vs. Rotary Vacuum Drum Filter?

Rotary Drum Filter vs. Rotary Vacuum Drum Filter

Choose Loway’s Gravity Rotary Drum Filter when:

✓ Feed concentration: 50-5,000 mg/L SS (0.005-0.5%solids)

✓ High flow rates: 10-500 m³/h with low to medium solids loading

✓ Applications: Municipal/industrial wastewater, aquaculture, food processing

✓ Budget conscious: 40-60% lower capital cost

✓ Energy efficiency priority: 70% less power consumption

✓ Simple operation required: Minimal operator training needed

Choose Rotary Vacuum Drum Filter (RVDF) when:

✓ High-concentration slurries: 3-30% solids content

✓Dewatering requirement: Final cake dryness 25-35%

✓ Applications: Chemical processing, mining tailings, pharmaceutical sludge

✓ Material characteristics: Fine particles requiring vacuum assist

✓ Continuous cake discharge: Thick cake formation needed

Side-by-side comparison:

Feature | Loway Gravity RDF | Rotary Vacuum DF |

Feed solids | 0.005-0.5% | 3-30% |

Cake dryness | N/A (screening only) | 25-35% |

Power consumption | 0.37-2.2 kW | 5-20 kW |

Maintenance | Low – simple mechanics | High – vacuum system |

Best for | High-volume liquid screening | Sludge dewatering |

Our honest recommendation: If your application involves sludge dewatering

with >3% solids or chemical slurries requiring vacuum assist, a gravity drum filter won’t meet your needs. We’ll tell you upfront – and can connect you with vacuum drum filter specialists if needed.

Q4: Rotary Drum Screen vs. Rotary Drum Filter?

Industry Terminology Clarification

These terms are often used interchangeably in the filtration industry. Here’s what you need to know:

“Rotary Drum Screen” typically refers to:

● Coarser applications (>200 microns)

● Primary screening for trash and debris removal

● Municipal intake screening

● Industrial process protection screens

“Rotary Drum Filter” emphasizes:

√ Finer filtration capability (20-500 microns)

√ Fine particle filtration

√ for suspended solids removal

√ Water quality improvement applications

√ Tertiary treatment and polishing

At Loway, we use “filter” to emphasize our capability for fine particle separation down to 20 microns-far beyond typical “screening” applications. However, our equipment can handle the full range from coarse screening to fine filtration, depending on mesh selection.

Whether you search for ” rotary drum screen ” or “rotary drum filter,” you’ll find the same technology. The difference is application-specific mesh selection, not equipment design.

Q5: What applications are rotary drum filters suitable for?

Rotary drum filters excel in applications requiring high-flow, continuous

solid-liquid separation with 85-95% suspended solids removal:

Primary applications:

• Wastewater treatment: Municipal and industrial pretreatment (50-300 m³/h typical)

• Aquaculture: RAS systems for fish farms – removes feed waste and fecal matter

• Food processing: Slaughterhouse, brewery, fruit/vegetable processing effluent

• Sludge dewatering: Pretreatment screening before belt presses/centrifuges

Industrial applications:

• Metal finishing rinse water

• CNC coolant filtration

• Paint booth water treatment

• Lithium battery production: Slurry filtration and material recovery

NOT suitable for:

• High-concentration chemical slurries (>5% solids) – requires vacuum drum filter

• Heavy mining applications – use specialized dewatering equipment

• Ultra-fine filtration <10 microns – consider membrane or sand filters

Contact our technical team for honest application assessment.

Q6: What warranty and after-sales support do you provide?

We stand behind our equipment with comprehensive warranty coverage and ongoing technical support.

Standard Warranty:

Duration: 12 months from commissioning date OR 18 months from shipment date (whichever comes first)

Coverage: All manufacturing defects in materials and workmanship

Includes: Replacement parts shipped at no charge.

Exclusions: Normal wear items (mesh screens, seals), damage from misuse, unauthorized modifications

Extended Warranty Options

After-Sales Support:

- Technical Support (Lifetime):

Email support, Phone/WhatsApp, Video support, and Remote access - Spare Parts Availability:

Common wear parts

stocked for immediate shipment (mesh screens, nozzles, seals)

Major components (motors, pumps, controls): 1-2 week lead time

Custom parts: 2-3 week fabrication + shipping

Q7:Can you customize the drum filter for my specific application?

Absolutely. Custom engineering is one of our core strengths – approximately 30% of our projects involve custom rotary drum filter designs.

Common customization requests:

• Dimensional Modifications:

• Non-standard height to fit under existing structures (we’ve built units as low as 1.2m)

• Extra-wide drums for very high flow rates (up to 2.5m width)

• Compact designs for space-constrained installations

• Mobile skid-mounted units with wheels for temporary applications

Material Upgrades:

• 316L stainless steel for corrosive environments

• Duplex stainless steel for extreme chloride exposure

• Food-grade PTFE/UHMW components for direct food contact

Functional Customizations:

Multiple inlet distribution systems for improved flow distribution

Integrated instrumentation: pH/ORP sensors, turbidity meters, flow meters

Special inlet/outlet orientations (top/side/bottom entry options)

Heated enclosures with insulation for cold climates (-20°C to -30°C)

Explosion-proof electrical systems (ATEX Zone 1/2, IECEx certified)

UV-resistant polycarbonate covers for outdoor tropical climates

Automation & Control:

• Remote monitoring

• SCADA integration

• Automatic chemical dosing coordination

• Variable frequency drives for precise flow control

• Advanced algorithms: predictive backwash triggering based on turbidity

Application-Specific Designs:

• Aquaculture: Ultra-fine 40-micron mesh, NSF-61 materials, gentle flow distribution

• Food processing: 3-A sanitary design, CIP-compatible, all-welded construction

• Lithium battery: Explosion-proof, closed-loop with vapor recovery

• Seawater: Full 316L construction, sacrificial anodes, marine-grade coatings

Q8: What is your custom design process:

1. Initial consultation: Application questionnaire, technical discussion, feasibility review

2. Preliminary design: Concept drawings, equipment list, budget quotation

3.Detailed engineering: P&ID, 3D model, electrical schematics, final specifications

4. Customer review & approval: Design review meeting, revision if needed

5. Contract & deposit

6. Fabrication

7. Factory testing

8. Shipment with documentation

Q9: What information we need for your customized rotary drum filter?

Required flow rate (m³/h)

Inlet solids concentration (mg/L)

Application/industry

Installation location (indoor/outdoor, climate)

Related Equipment & Complete Dewatering Systems

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Portable solutions for temporary sites

Dewatering Screw Press

Continuous operation for efficient sludge treatment