Vacuum Belt Filter Press: Continuous Filtration, Superior Cake Washing, and Maximum Dryness

Break free from batch processing bottlenecks. Loway Vacuum Belt Filter Press integrates vacuum dewatering with mechanical compression to deliver 24/7 uninterrupted production, lower operational costs, and exceptional filtrate clarity.

Redefining Efficiency in Industrial Separation

For industries dealing with large-volume slurries, traditional batch filters (like plate presses) often create production bottlenecks. LOWAY’s Vacuum Belt Filter Press is engineered to solve this by providing a truly continuous solution.

By combining vacuum suction with a multi-roll mechanical compression zone, our system achieves cake moisture levels (15-30%) comparable to batch presses but with the high throughput of continuous belts. Whether for mining tailings, FGD gypsum, or chemical catalysts, LOWAY equipment is designed to maximize recovery rates while minimizing energy consumption and labor.

Why Upgrade to a Vacuum Belt Filter?

- True Continuous Operation: Eliminates downtime associated with batch loading/unloading.

- Superior Washing Efficiency: Counter-current washing recovers up to 99.8% of valuable filtrate (e.g., catalysts) or removes impurities effectively.

- Lower OPEX: Consumes 40% less energy than centrifuges (0.5-1.2 kWh/m³) and reduces labor by up to 80% via automation.

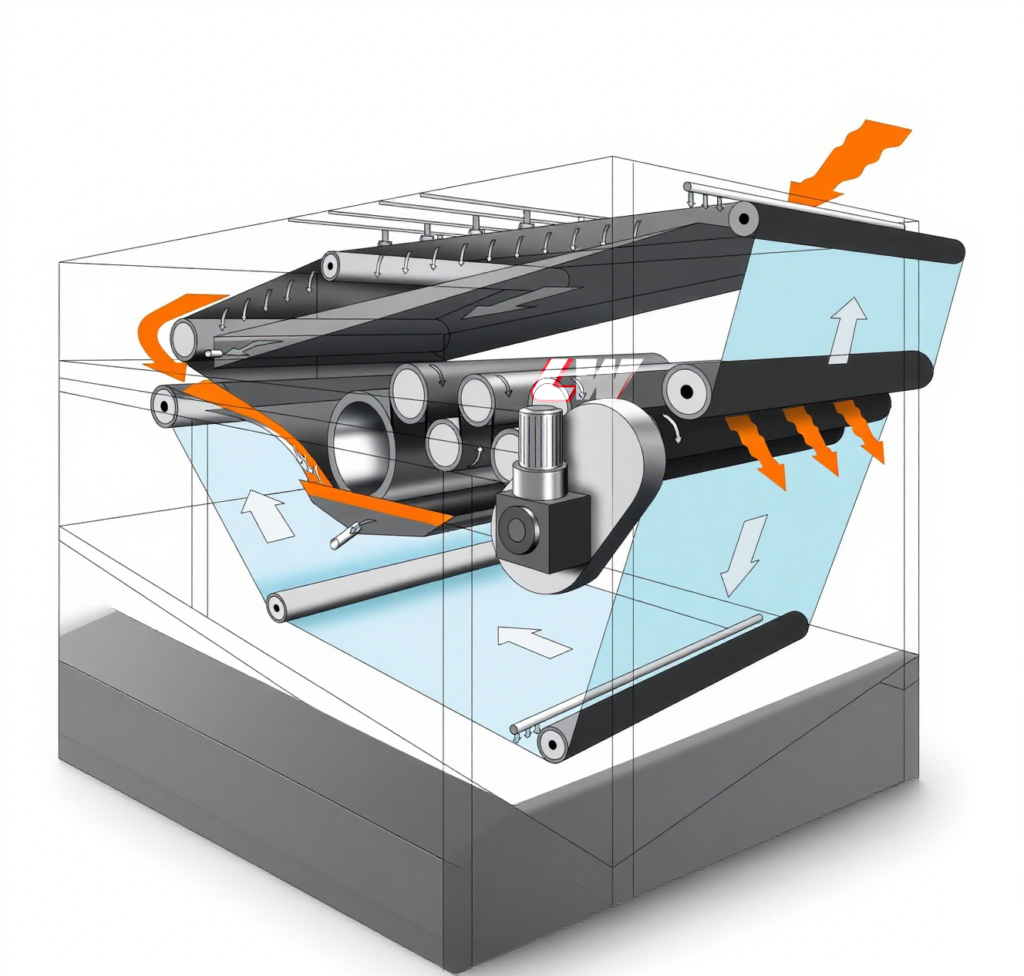

A 5-Stage Continuous Process

Working Principle of The Loway system operates on a precise, continuous cycle that optimizes separation at every step:

- 1. Uniform Feeding: Slurry is evenly distributed onto the moving filter belt. An anti-clog feeder prevents uneven filtration.

- 2. Gravity Pre-Dewatering: Free water drains naturally by gravity, removing 30-40% of moisture immediately to reduce the load on the vacuum system and save energy.

- 3. Vacuum Deep Dewatering: The belt travels over a stationary vacuum box (316L Stainless Steel). Stable negative pressure (-0.075 to -0.095 MPa) rapidly extracts moisture through the filter cloth.

- 4. Counter-Current Washing (Optional): Wash liquors are sprayed over the cake. The vacuum pulls the wash fluid through the cake, efficiently displacing mother liquor for maximum product purity.

- 5. Mechanical Compression & Discharge: The cake enters an "S" configuration of compression rollers. Gradual shearing pressure squeezes out residual capillary water before the scraper blade discharges the dry cake.

Important Distinction: Cake Washing vs. Cloth Washing

Many clients ask: “Standard filter presses also have auto-washing, what’s the difference?”

Standard Filter Press “Washing”: This usually refers to High-Pressure Cloth Cleaning. It sprays water on the filter cloth after the cake is discharged to unclog the pores. It does not effectively wash the product itself.

Loway Vacuum Belt Filter “Cake Washing”: This is a true Process Washing. Because the filter cake sits flat on the belt, we can spray fresh solvent or water directly through the cake while it is under vacuum. This “Plug-Flow” displacement efficiently washes out impurities (like chlorides) or recovers valuable mother liquor (like dissolved gold or lithium) from inside the cake structure.

- Benefit: We can achieve >99% washing efficiency with minimal wash water usage, something a standard plate press or centrifuge simply cannot do.

Engineered for Reliability and Durability

Key Features & Structural Advantages of Loway vacuum Belt Filter

Patented Vacuum Adsorption System:

Features a fixed vacuum box with a moving rubber belt seal. The integrated gas-liquid separator protects the pump, extending service life to over 8,000 hours.

Intelligent PLC Automation:

A centralized control system (Siemens/Omron) monitors 12 key parameters, including belt speed (0.1-5 m/min) and vacuum pressure. It automatically adjusts to feed fluctuations within 0.5 seconds, ensuring uniform cake thickness without manual intervention.

Corrosion-Resistant Design:

Built to last in harsh environments (pH 1-14). Contact parts are available in 316L Stainless Steel, Hastelloy, or lined with PTFE.

Modular Vacuum Zone:

Independent vacuum trays allow for flexible length configurations to match specific capacity needs and enable easier maintenance without full system shutdowns.

Model Selection Guide

Select the right model based on your throughput requirements. Loway engineers can assist with sizing based on slurry viscosity and solid content.

Parameter | VBF-1000 | VBF-1500 | VBF-2000 | VBF-2500 |

Belt Width | 1000 mm | 1500 mm | 2000 mm | 2500 mm |

Throughput Capacity | 5 – 20 m³/h | 20 – 40 m³/h | 40 – 70 m³/h | 70 – 100 m³/h |

Cake Output | 1 – 5 t/h | 5 – 12 t/h | 12 – 20 t/h | 20 – 30 t/h |

Typical Vacuum | -0.075 ~ -0.09 MPa | -0.075 ~ -0.095 MPa | -0.08 ~ -0.095 MPa | -0.08 ~ -0.098 MPa |

Main Motor Power | 5.5 kW | 7.5 kW | 11 kW | 15 kW |

Ideal For | Small Chemical/Food Plants | Medium Mining/Municipal | Large Power Plant (FGD) | Mega Mines/Chemical Parks |

Note: Specifications based on standard conditions. High-temperature (≤120℃) options available.

Tailored Process Solutions for Demanding Industries

Chemical Processing: High-Purity Filtration & Recovery

In chemical manufacturing, achieving high product purity and maximizing the recovery of expensive solvents are critical KPIs. Our system excels in “Cake Washing” efficiency where centrifuges fail.

Applications:

- Pigment & Dyes: Iron Oxide, Titanium Dioxide, organic pigments.

- Catalyst Recovery: Precious metal catalysts, zeolites.

- Battery Materials: Lithium Carbonate/Hydroxide, precursors (NCM).

Key Process Advantages:

- True Cake Washing (Solvent Displacement): Unlike simple rinsing, we utilize multi-stage counter-current washing. Vacuum suction pulls fresh solvent through the cake, effectively displacing mother liquor to achieve >99.5% purity.

- Corrosion Resistance: Engineered with Hastelloy, 904L, or PVDF/PTFE lining to withstand aggressive acids (pH < 1) and solvents.

Power Generation & Environmental: Gypsum Dewatering (FGD)

Coal-fired power plants use Flue Gas Desulfurization (FGD) scrubbers that produce gypsum. The commercial value of this gypsum depends entirely on removing chloride impurities.

Applications:

- FGD Gypsum: Scrubber sludge from power plants.

Key Process Advantages:

- Chloride Removal: Our spray-wash system effectively removes chlorides to <100ppm, ensuring the gypsum cake meets specifications for commercial sale (e.g., for wallboard or cement production).

- Consistent Dryness: Delivers a stable cake with <10% free moisture, preventing clogging in downstream transport or calcination equipment.

Industrial Wastewater: Volume Reduction

For general industrial sludge, the goal is purely OPEX reduction: minimizing weight and volume.

Applications:

- Phosphogypsum: Fertilizer plant by-products.

- Electroplating Sludge: Heavy metal-laden waste.

Key Process Advantages:

- Continuous Throughput: Handles large flow rates continuously, eliminating the need for massive holding tanks required by batch filter presses.

- Disposal Savings: Reduces sludge volume by up to 60%, drastically cutting hauling and hazardous waste disposal fees.

Mining & Metallurgy: Resource Recovery & Dry Stacking

Mining operations require equipment that handles massive throughputs of abrasive slurry while maximizing the recovery of valuable leachate (e.g., gold, copper).

Applications:

- Mineral Concentrates: Copper, Zinc, Lead, Iron concentrates.

- Hydrometallurgy Residues: Leaching residues (Gold/Silver/Uranium) requiring cyanide/acid recovery.

- Tailings Management: Dry stacking of fine tailings.

Key Process Advantages:

- Leachate Recovery: The vacuum belt filter efficiently washes the filter cake to recover dissolved metals from the residue, significantly increasing the mine’s total yield.

- Low Moisture Output: Achieves cake moisture levels of 10-15% for concentrates and <20% for tailings, minimizing transport costs and eliminating wet tailings ponds.

Food & Pharmaceutical: Sanitary Production & Yield

Hygiene compliance and maximizing yield from high-value feedstocks are the priorities here.

Applications:

- Fermentation Broths: Citric acid, penicillin, amino acids.

- Food Processing: Starch washing, edible oil bleaching earth, fruit pulp.

Key Process Advantages:

- Sanitary Design (GMP): Available in polished 316L Stainless Steel with food-grade belts and easy-clean (CIP) capability.

- Yield Maximization: The combination of vacuum and mechanical compression extracts more liquid product (juice or broth) per ton of biomass than standard gravity filters.

Livestock & Agriculture: Manure Management & Nutrient Control

Large-scale dairy and swine farms face strict environmental regulations regarding nutrient runoff. While screw presses are common, Vacuum Belt Filters offer superior separation performance for fine solids and nutrients.

Applications:

- Dairy Manure Flushing: Processing flushed manure wastewater.

- Swine Lagoon Sludge: Dewatering digested pig manure.

- Biogas Digestate: Solid-liquid separation after anaerobic digestion.

Key Process Advantages:

- High Nutrient Capture (P & N): The fine filtration cloth captures fine solids that contain the majority of Phosphorus and Organic Nitrogen, preventing them from entering the liquid stream and causing eutrophication in storage lagoons.

- Clearer Filtrate: Produces a filtrate with significantly lower Total Suspended Solids (TSS) compared to screw presses, reducing the load on downstream biological treatment or wetlands.

- Bedding Recovery: The separated solids (with appropriate post-treatment) can be reused as Recycled Manure Solids (RMS) bedding or high-value organic fertilizer.

Feature | LOWAY Vacuum Belt Filter | Chamber/Plate Press | Decanter Centrifuge |

Operation | Continuous (24/7) | Batch (Stop/Start) | Continuous |

Washing Type | True Cake Washing (Displacement) | Cloth Washing Only (Usually) | None |

Washing Efficiency | Excellent (Counter-current) | Good | Poor |

Cake Moisture | Low (15-30%) | Very Low (10-30%) | Medium (10-25%) |

Energy Usage | Low (0.5-1.2 kWh/m³) | Medium | High (2-5 kWh/m³) |

Labor Req. | Low (Fully Auto) | Medium/High | Low |

Best For | Large volume, washing needed | Maximum dryness priority | Limited space, no washing |

- Precision Manufacturing & Quality Control

- State-of-the-Art Facility: Our ISO 9001-certified factory is equipped with advanced CNC machining centers and automated welding robots to ensure structural precision and durability.

- Rigorous Testing: Every vacuum belt filter undergoes a 48-hour continuous running test (load simulation) before leaving our floor. We check vacuum tightness, belt tracking accuracy, and noise levels to ensure zero defects upon arrival.

- Custom Engineering & Design

- Tailored Solutions: We understand that every slurry is unique. Our engineering team uses advanced 3D CAD/SolidWorks to customize the equipment layout, ensuring it fits perfectly into your existing plant footprint.

- Material Science Expertise: Whether you need super-duplex stainless steel for high-chloride environments or food-grade polymers for hygiene, we design the material of construction (MOC) to match your specific process chemistry.

- Global Service & Life-Cycle Care

- Process Optimization: Our support doesn’t end at delivery. We offer remote diagnostics and process optimization advice to help you maximize yield as your production scales.

- Training & Commissioning: We provide comprehensive operator training (on-site or digital) to ensure your team is confident in running the machine efficiently from Day 1.

Frequently Asked Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: When should we choose a vacuum belt filter over a standard filter press?

Choose a vacuum belt filter if your priority is continuous processing and high washing efficiency. While a filter press may get the cake slightly drier, the vacuum belt filter eliminates batch downtime and offers superior recovery of valuable filtrates through washing.

Q2: Can the vacuum belt filter press handle corrosive or abrasive slurries?

Yes. For corrosive environments (pH 1-14), we use 316L Stainless Steel, Hastelloy, or PTFE contact parts. For abrasive mining slurries, we equip the machine with wear-resistant filter cloths and reinforced rubber belts.

Q3: What is the maintenance requirement?

Maintenance is minimal due to the modular design. Routine tasks include checking belt tracking and cleaning the cloth (automated). Major wear parts like filter cloths typically last 6-12 months and can be replaced by two people in under 30 minutes.

Q4: Do you offer testing services?

Yes. We strongly recommend our Free Material Testing Service. Send us a 500g slurry sample, and we will conduct viscosity and dewatering tests to confirm the exact model and expected moisture content for your project.

Q5: How is the vacuum belt filter equipment shipped and installed? Is it "plug-and-play"?

Yes, for most models (belt width < 2.5m), we utilize a skid-mounted design. The main unit is pre-assembled and factory-tested before shipment. On-site installation is simple: just connect the power, water, and feed pipes. For larger custom units, we provide modular assemblies and detailed 3D installation guides, or we can dispatch engineers for on-site supervision.

Q6: What happens if my feed concentration or flow rate fluctuates?

Our system is designed to handle variability. The integrated PLC & VFD (Variable Frequency Drive) system monitors feed conditions in real-time. If the slurry concentration drops, the system automatically slows down the belt speed to ensure the cake has enough time to dry, maintaining consistent output quality without operator intervention.

Q7: Are spare parts standard or proprietary? How fast can I get them?

We use standard, globally recognized brands for critical components (e.g., SEW/Nord motors, Siemens/Schneider electrics) to ensure you can find replacements locally. For proprietary parts like filter belts or rubber seals, we maintain a “Critical Stock” inventory and offer rapid air-freight shipping to ensure minimal downtime.

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Microfiltration filtration for municipal and industrial wastewater

Dewatering Screw Press

Continuous operation for efficient sludge treatment