Custom-Engineered Filter Press Plates: Precision Matched to Your Process

From standard Recessed Chamber to high-pressure Membrane and CGR designs. We manufacture 100% Virgin Polypropylene (PP) and specialty metal plates that guarantee universal compatibility with any filter press brand.

Key Value Points:

- Universal Fit: Replacements for all major global brands.

- High Pressure: Rated up to 30 Bar (435 psi).

- Material Quality: CNC-milled surfaces for zero leakage.

Precision-Engineered Plates: The Heart of Your Filtration Process

In industries like Mining, Chemical, and Wastewater, the filter plate is not just a spare part—it is the decisive factor for filtration efficiency, cake dryness, and operational continuity.

With over a decade of R&D and manufacturing expertise, Loway Equipment goes beyond standard replacements. We focus on “Material-to-Process Matching” and “Structural Optimization” to solve your most persistent headaches: leakage, premature wear, and incomplete separation.

Our mission is simple: To provide customized filter plate solutions that drive down your operational costs and boost production efficiency.

Loway Filter Plates Categories

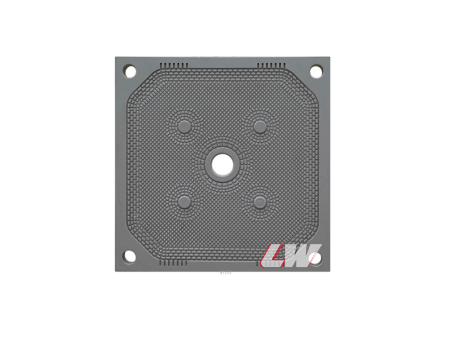

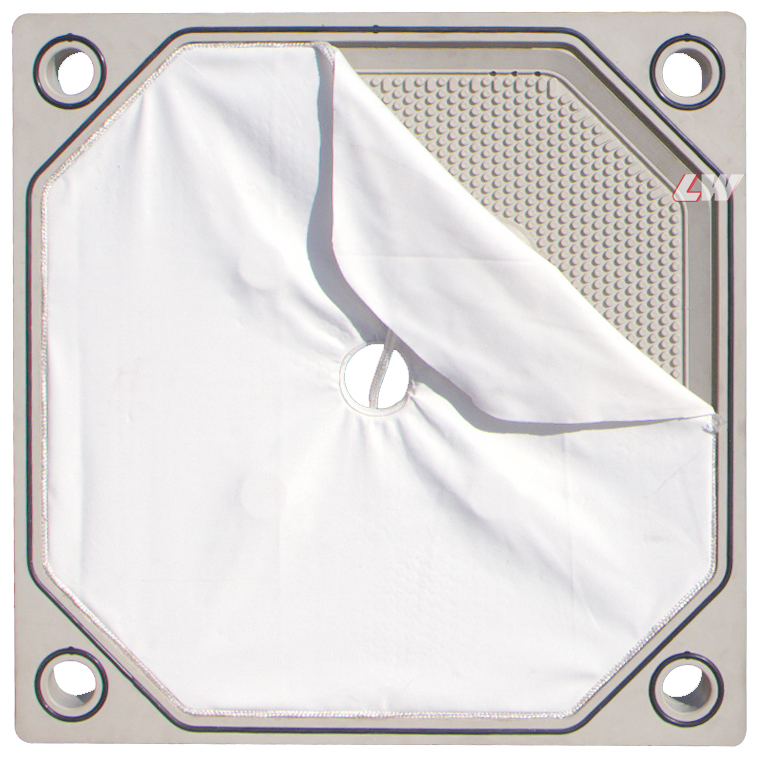

The industry standard for general dewatering. Features a dual-sided recessed structure to form the filtration chamber. Durable and efficient, it is ideal for mining tailings, wastewater, and standard industrial sludge.

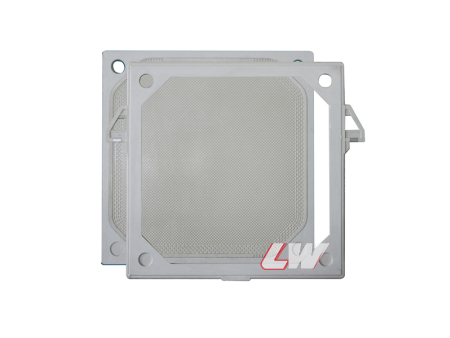

Consists of a separate flat plate and hollow frame. Designed for precision filtration using filter paper or fine pads. Perfect for chemical and pharmaceutical applications requiring ultra-high filtrate clarity.

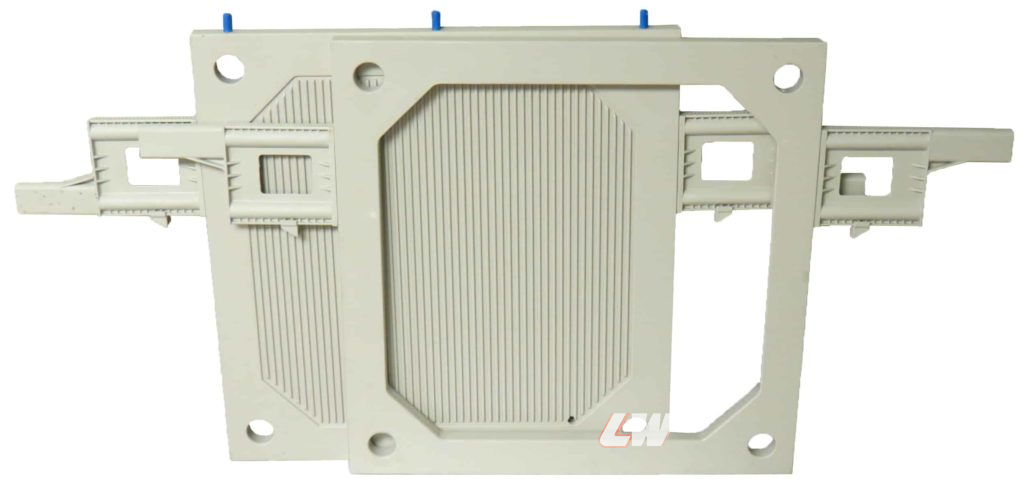

Features a grooved edge where the filter cloth is "embedded" or caulked in. This gasketed design creates a hermetically sealed chamber, ensuring zero leakage for toxic or volatile chemical filtration.

Modified PP enhanced with glass fiber or special fillers. Offers superior heat resistance and structural rigidity, capable of withstanding higher feed pressures (up to 25 bar) without deformation.

Constructed with a steel core encapsulated in high-grade rubber. Combines extreme strength with surface elasticity, making it ideal for high-pressure squeezing and abrasive slurries where standard PP might wear out.

Manufactured from SUS304 or 316L. The top choice for high-temperature processes or hygiene-critical (GMP) applications in food, beverage, and pharmaceutical industries. Easy to clean and sterilize.

Comprehensive Plate Configurations

- Design: Single-piece construction with dual-sided recesses forming independent chambers. Thickness: 60mm.

- Size Range: From 500mm to 2000mm.

- Why Choose It: Unlike Plate & Frame, these are easier to automate and discharge. Increases continuous operation efficiency by 30%+.

- Ideal For: Mining tailings, large-scale industrial sludge.

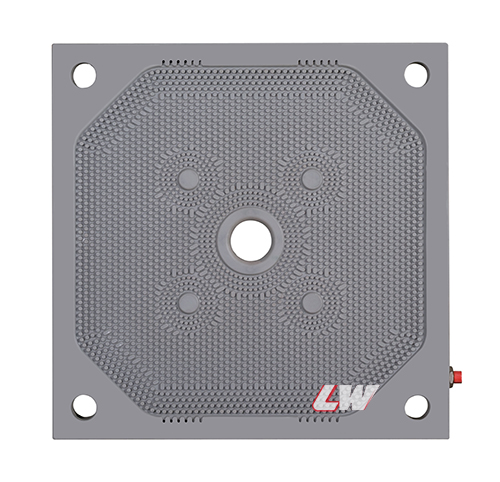

- Design: Features built-in flexible membranes (PP/EPDM) that inflate to squeeze the cake after filtration.

- Performance: Secondary squeezing reduces cake moisture by an additional 10%-15% compared to standard chamber plates.

- Ideal For: “Dry Stacking” requirements in mining and reducing municipal sludge disposal costs.

- Design: Alternating “Plate + Frame” structure. Thickness: 30mm.

- Size Range: Compact sizes from 315mm to 1000mm.

- Performance: Allows the use of filter paper/pads for high precision (5-20μm). Flexible capacity—just add or remove frames to adjust batch volume.

- Ideal For: Fine chemical batches, dye filtration, and polishing applications.

- Design: “Caulked, Gasketed, Recessed.” Features a CNC-milled groove with an O-ring seal.

- Performance: Creates a hermetically sealed chamber. Zero drip, zero odor.

- Ideal For: Toxic chemicals, volatile solvents, and pharmaceutical environments.

Material Science for Extreme Environments

Select the right material grade based on your Pressure, Temperature, and Chemical needs.

Material Grade | Composition | Pressure Rating | Temp. Limit | Best Application |

Recycled PP | Recycled Polypropylene | Low (≤0.6 MPa) | 70°C | Economy Choice. Simple wastewater, stone cutting, non-critical filtration. |

Reinforced PP | PP + Fillers (Calcium) | Standard (≤1.0 MPa) | 80°C | General Purpose. Standard municipal sludge, light industrial wastewater. |

Virgin PP | 100% Pure Polypropylene | High (≤1.6 MPa) | 90°C | Industry Standard. Chemical, Mining, pigments. High tensile strength & long life. |

Glass Fiber PP | PP + Glass Fiber (RCPP) | Ultra-High (≤2.5 MPa) | 100°C | High Pressure/Temp. For membrane squeezing >16 bar or high-temp slurries. |

PVDF | Polyvinylidene Fluoride | Standard (≤1.0 MPa) | 110°C+ | Extreme Corrosion. Concentrated acids/alkalis where PP fails. |

Cast Iron | Nodular Cast Iron | High (≤1.6 MPa) | 200°C+ | High Temp. Petroleum, hot oil filtration, ceramic slip. |

Stainless Steel | SUS304 / 316L | Medium (≤1.0 MPa) | 150°C | Hygienic (GMP). Food, Beverage, Pharma. Easy CIP cleaning. |

Precision Engineering: Designed for Zero Leakage

Optimized Filtration Surface

- Design: Composite

“Diamond + Strip” pips pattern. - Benefit: Provides stable support for the filter cloth while creating high-flow drainage channels. Channel depth is dynamically controlled (1.2-2.0mm) to ensure uniform cake formation.

Zero-Leakage Sealing System

- Design: “Stepped Sealing Groove + Elastic O-Ring” configuration.

- Precision: Processed via CNC milling, the sealing face flatness error is strictly controlled to ≤0.05mm—the industry’s tightest tolerance.

Reinforced Core Structure

- Design: Plate core features Cross-Shaped Reinforcement Ribs.

- Benefit: Increases material density by 20% in critical stress zones. Tested to withstand 1.6 MPa working pressure with zero deformation, extending service life by 50%.

Flexible Interface Design

- Customization: We flexibly adjust hole positions (feed/discharge) and diameters to match your existing piping system, ensuring a drop-in replacement.

Customized to Your Specifications

We stock standard sizes but specialize in custom replacements.

- Size Range: From lab-scale 470mm to massive 2000mm plates.

- Feed Styles: Center feed, Corner feed, Top feed – matched to your existing piping.

- Handle Options: Compatible with various shifting systems (Automatic or Manual).

- Pressure Rating: Standard 7 bar, Medium 16 bar, Ultra-High 30 bar.

Not sure about the specs? Send us a photo or drawing of your current plate, and our engineers will identify the mold match.

Technical Parameters of Filter Press Plates

| Plate Size (mm) | Common Chamber Depths (mm) | Typical Filtration Area per Plate (m²) | Suitable Applications |

|---|---|---|---|

| 250 × 250 | 15, 20, 25, 30 | 0.04 – 0.06 | Laboratory, small-scale production |

| 500 × 500 | 20, 25, 30, 40 | 0.20 – 0.25 | Small industrial applications |

| 630 × 630 | 25, 30, 32, 40 | 0.31 – 0.40 | Medium capacity requirements |

| 800 × 800 | 30, 32, 40, 50 | 0.50 – 0.64 | Medium to large industrial use |

| 1000 × 1000 | 30, 32, 40, 50, 60 | 0.80 – 1.00 | Heavy industrial applications |

| 1200 × 1200 | 32, 40, 50, 60 | 1.15 – 1.44 | Large capacity industrial systems |

| 1500 × 1500 | 40, 50, 60, 80 | 1.80 – 2.25 | High-volume processing |

| 2000 × 2000 | 50, 60, 80, 100 | 3.20 – 4.00 | Maximum capacity operations |

| Parameter | Standard Range | High-Performance Range | Critical Considerations |

|---|---|---|---|

| Operating Pressure | 6-10 bar | 10-30 bar | Material strength, plate design, press frame capacity |

| Temperature Limit | 20-80°C | 80-250°C | Plate material, gasket selection, thermal expansion |

| pH Range | 2-12 | 0-14 | Material compatibility, gasket selection |

| Cake Thickness | 15-50 mm | Up to 80 mm | Chamber depth, slurry characteristics |

| Cycle Time | 1-4 hours | 20 min – 8 hours | Slurry properties, automation level, plate design |

| Dry Solid Content | 50-70% | 70-90% | Membrane application, feed solids, material properties |

The 6-Stage "Zero Defect" Quality Protocol

Strict process control from raw granule to final shipment.

- Raw Material Validation

We verify every batch before use. PP Melt Index is strictly controlled (0.5-1.5g/10min), and moisture is kept below 0.05% to prevent internal air bubbles and voids.

- Precise Compounding

Automated dosing adds anti-oxidants and UV stabilizers with a mixing error of <1%. This ensures every inch of the plate has uniform chemical resistance.

- High-Pressure Molding

We utilize real-time monitoring of injection pressure and temperature (180-220℃) to guarantee high material density and structural strength.

- Controlled Cooling

To prevent warping, we use a dual Wind & Water cooling system. Custom cooling cycles lock in dimensional stability before the plate is ejected.

- CNC Finishing

For a perfect seal, all sealing faces are CNC milled to a flatness of ≤0.1mm. We use Liquid Nitrogen trimming to ensure edges are smooth and burr-free.

- Final Performance Audit

No plate ships without passing four torture tests:

Pressure: 1.5x working pressure for 30 mins (No leakage).

Corrosion: 72-hour immersion in Acid/Alkali.

Dimension: 100% 3D CMM scanning.

Visual: Zero cracks or surface defects.

At Loway Equipment, we’re committed to helping you optimize your processes with reliable and efficient filter press solutions.

Contact us today to learn more about how our filter presses can help improve your operations’ efficiency, productivity, and sustainability.

Empowering Industries with Tailored Separation Solutions

Environmental & Municipal Wastewater

- Challenge: High disposal costs for sludge (>80% moisture).

- Solution: High-strength PP Membrane Plates.

- Result: Reduced cake moisture to <60%, cutting disposal costs by 25% and enabling resource utilization (brick making).

Mining & Metallurgy

- Challenge: Abrasive tailings wearing out plates.

- Solution: Cast Iron or Reinforced PP plates (2.5 MPa) with abrasion-resistant coating.

- Result: Service life extended by 100% (2x). Efficiently recycles process water for zero-discharge targets.

Chemical Processing

- Challenge: Corrosion and product purity.

- Solution: Virgin PP or 316L Stainless Steel plates.

- Result: Zero contamination. Improved dye purity and color stability, eliminating secondary purification costs.

Food & Pharmaceutical

- Challenge: Hygiene and GMP compliance.

- Solution: GMP-compliant Stainless Steel/Food-Grade Rubber plates.

- Result: Efficient separation of juice/fermentation broth. Supports clients in passing FDA and GMP audits.

Frequently Asked Questions About Filter Plates

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How do I decide between Recessed Chamber and Membrane plates?

Recessed Chamber plates are the standard, cost-effective choice for general dewatering. Membrane plates are an upgrade; they have flexible faces that inflate (squeeze) after filtration. Choose Membrane if you need:

Lower Moisture: Squeezing extracts 10-20% more liquid.

Shorter Cycles: Faster filtration times.

Variable Volume: The ability to stop the cycle early if the chamber isn’t 100% full.

Q2: How do I know when filter press plates need replacement?

Signs that indicate replacement is needed include: visible cracks or deformation, consistent leakage despite proper cloth installation, uneven cake formation, decreased filtration efficiency, and excessive wear on contact surfaces or feed holes.

Q3: Can different types of plates be used in the same filter press?

Yes, mixed pack configurations using different plate types (such as standard and membrane plates) are common and can optimize performance for specific applications. However, the plates must be compatible in terms of size, feed system, and connection design.

Q4: What's the maximum pressure filter press plates can withstand?

Maximum pressure capacity depends on plate material and design:

- Polypropylene plates: Typically 7-16 bar

- Cast iron plates: Up to 16-30 bar

- Stainless steel plates: Up to 30 bar or higher in specialized designs Always verify specifications with the manufacturer and ensure the entire filter press system is rated for the intended operating pressure.

Q5: How do I prevent leakage between filter press plates?

To prevent leakage:

- Ensure proper filter cloth selection and installation

- Check for proper plate alignment during assembly

- Apply appropriate closing pressure

- Inspect and maintain gaskets or sealing surfaces

- Avoid pressure spikes during operation

- Replace damaged plates promptly

Q6: My slurry temperature is 120°C. Is Polypropylene (PP) safe to use?

Standard PP plates are rated up to 90°C. For temperatures between 90°C and 110°C, we can offer a high-temp reinforced PP blend. However, for temperatures exceeding 120°C (up to 200°C+), we strongly recommend switching to our Cast Iron or Stainless Steel plates to prevent warping and structural failure.

Q7: What is the expected lifespan of your filter plates?

Lifespan varies by usage and slurry abrasiveness.

Virgin PP (Grade A): Typically lasts 4-6 years under normal conditions.

Recycled PP (Grade B): Typically lasts 1-3 years.

Metal Plates: Can last 10+ years with proper maintenance.

Pro Tip: Regular cleaning of the sealing surfaces significantly extends plate life by preventing uneven pressure.

Q8: How often should filter press plates be cleaned?

Cleaning frequency depends on the application:

- For clear filtrates with minimal residue: Every 20-50 cycles

- For sticky or residue-heavy applications: Every 5-15 cycles

- For critical or high-purity applications: After each batch Establish a cleaning schedule based on observed performance and product quality requirements.

Q9: Do you offer CGR (Gasketed) plates for zero-leakage requirements?

Yes. For toxic, acidic, or high-value applications where drip leakage is unacceptable, we provide CGR plates. These feature a grooved edge fitted with an O-ring (EPDM, Viton, or Silicone) and use “clip-on” or “barrel-neck” filter cloths to create a hermetically sealed chamber during filtration.

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Portable solutions for temporary sites

Dewatering Screw Press

Continuous operation for efficient sludge treatment