Precision Filtration & Polishing: The Plate and Frame Filter Press

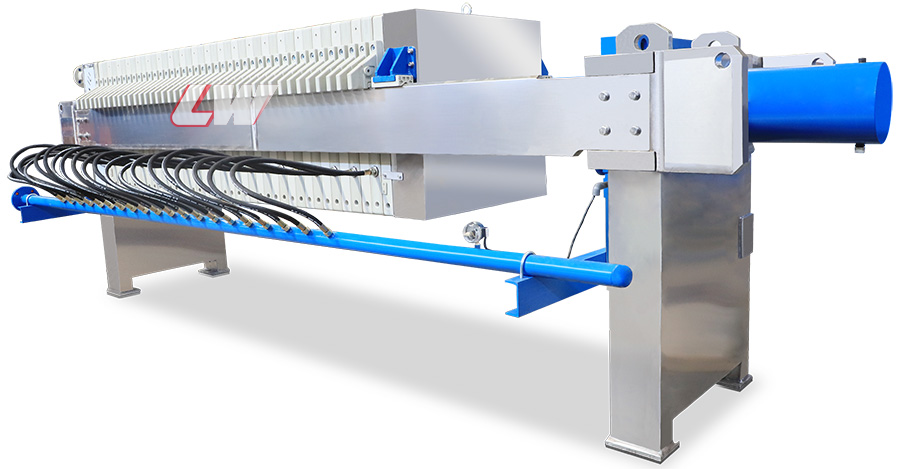

Engineered for industries requiring maximum filtrate clarity. Featuring a versatile "Plate + Frame" design compatible with filter paper and fine pads. Available in Stainless Steel (GMP) and Cast Iron for high-value applications.

The Specialist for Fine Separation

For project managers seeking absolute purity, the choice of equipment is critical. While recessed presses handle bulk sludge, LOWAY EQUIPMENT’s Plate and Frame Filter Press stands as the proven solution for precision filtration and liquid polishing.

Unlike standard dewatering machines, our Plate & Frame design allows for the use of Filter Paper or High-Density Pads. This makes it capable of capturing ultra-fine particles (down to 1 micron) that pass through standard filter cloths. From edible oil fractionation to pharmaceutical serum clarification, this machine delivers the crystal-clear filtrate your process demands.

How It Works

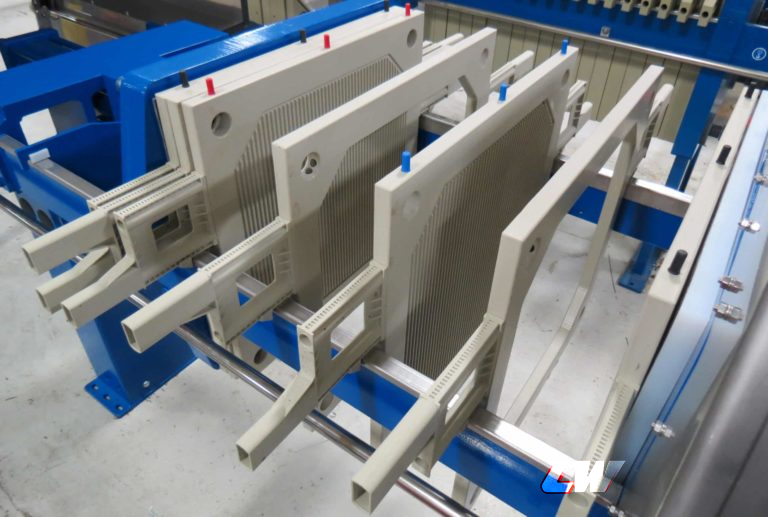

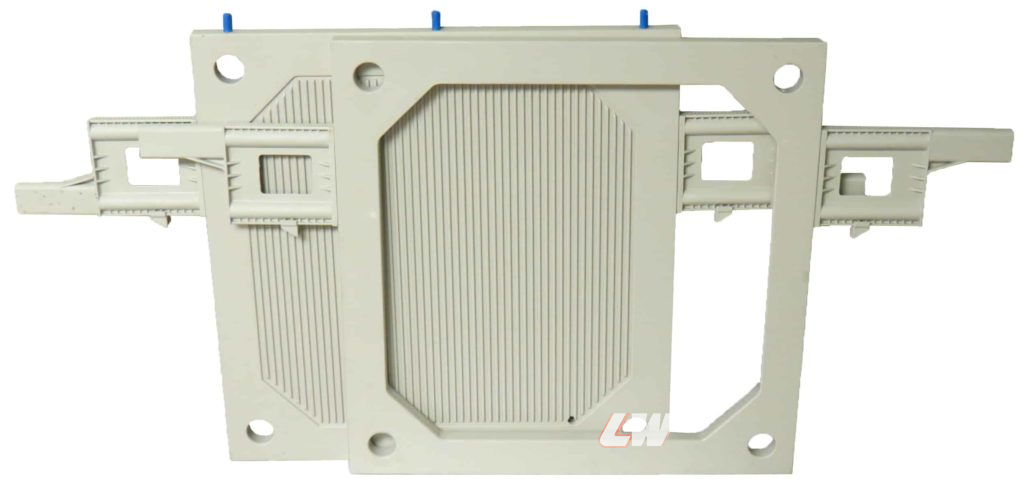

The machine consists of alternating Solid Plates and Hollow Frames, aligned on a skeleton. The filter medium (Cloth or Paper) is sandwiched between them.

Discharge Options:

- Open Delivery: Visible spigots for monitoring filtrate clarity from each chamber.

- Closed Delivery: Piped manifold for volatile, toxic, or hygienic fluids.

Why Choose Plate & Frame?

- Media Versatility

The only design compatible with Filter Paper, essential for ultra-fine filtration, where cloth is not enough.

- Material Flexibility

We manufacture frames in Stainless Steel (304/316L) for Pharma/Food, Cast Iron for High-Temp Oil, and Reinforced PP for general chemical use.

- Adjustable Capacity

Easily scale your batch size up or down by simply adding or removing frames and plates.

- Superior Clarity

Achieves the highest filtrate clarity of any pressure filter type, making it ideal for final product polishing.

Standard Specifications

Feature | Specification |

Filter Area | 1 m² to 160 m² (Scalable) |

Plate Sizes | 320mm, 450mm, 630mm, 800mm, 1000mm |

Frame Thickness | 25mm / 30mm / 45mm (Customizable) |

Operating Pressure | Standard 0.6 MPa (High pressure available) |

Temperature | Up to 200°C (with Cast Iron/Metal plates) |

Loway Plate and Frame Filter press Technical Parameter Table

650-U (BK) Plate and Frame Filter Press Technical Parameters | ||||||||||

| Technical parameters: Cylinder working stroke 360, maximum stroke 400, filter plate size length × width × thickness: 650*650*30; hydraulic clamping, automatic pressure maintenance, mechanical pressure maintenance | ||||||||||

| Model | Filtration area (m²) | Filter plate/filter frame quantity | Filter cake thickness (mm) | Filter chamber volume | Foundation size (mm) | Machine weight (Kg) | Dimensions (mm) | |||

| L | W | H | ||||||||

| BA MY5/650-U (BK) | 5 | 11 | 10 | 30 | 80 | 1500 | 970 | 1800 | 1070 | 1150 |

| BA MY10/650-U(BK) | 10 | 21 | 20 | 160 | 2100 | 1160 | 2480 | |||

| BA MY15/650-U(BK) | 15 | 31 | 30 | 240 | 2700 | 1360 | 3080 | |||

| BA MY20/650-U(BK) | 20 | 41 | 40 | 320 | 3300 | 1560 | 3680 | |||

| BA MY25/650-U (BK) | 25 | 51 | 50 | 400 | 3900 | 1750 | 4280 | |||

| BA MY30/650-U (BK) | 30 | 61 | 60 | 480 | 4500 | 1940 | 4880 | |||

800-U(BK) filter press technical parameter table | ||||||||||

Technical parameters: working stroke 380, maximum stroke 410, filter plate size L*W*T: 800*800*30; frame size L*W*T: 800*800*30; Hydraulic clamping, automatic pressure maintenance | ||||||||||

Model | Filtration area | Filter plate/filter | Filter cake thickness | Filter chamber volume | Foundation size | Machine weight | Dimensions (mm) | |||

L | W | H | ||||||||

BA MY20/800-U(BK) | 20 | 21 | 20 | 30 | 320 | 2360 | 2150 | 3030 | 1070 | 1150 |

BA MY30/800-U(BK) | 30 | 31 | 30 | 480 | 2960 | 2700 | 3630 | |||

BA MY40/800-U(BK) | 40 | 41 | 40 | 640 | 3560 | 3250 | 4230 | |||

BA MY50/800-U(BK) | 50 | 51 | 50 | 800 | 4160 | 3800 | 4830 | |||

BA MY60/800-U(BK) | 60 | 61 | 60 | 960 | 4760 | 4350 | 5430 | |||

BA MY70/800-U(BK) | 70 | 71 | 70 | 1120 | 5360 | 4900 | 6030 | |||

BA MY80/800-U(BK) | 80 | 81 | 80 | 1280 | 5960 | 5450 | 6630 | |||

870-U (BK) filter press technical parameter table | ||||||||||

Technical parameters: working stroke 460, maximum stroke 660, filter plate size length × width × thickness: 870mm*870mm*30mm; Hydraulic clamping, automatic pressure maintenance | ||||||||||

Model | Filtration area | Filter plate/filter frame quantity | Filter cake thickness | Filter chamber volume | Foundation size | Machine weight | Dimensions (mm) | |||

L | W | H | ||||||||

BA MY20/870-U(BK) | 20 | 19 | 18 | 30 | 320 | 2210 | 2600 | 3030 | 1140 | 1230 |

BA MY30/870-U(BK) | 30 | 27 | 26 | 480 | 2750 | 2880 | 3630 | |||

BA MY40/870-U(BK) | 40 | 36 | 35 | 640 | 3560 | 2150 | 4230 | |||

BA MY50/870-U(BK) | 50 | 45 | 44 | 800 | 4160 | 3450 | 4830 | |||

BA MY60/870-U(BK) | 60 | 54 | 53 | 960 | 4760 | 3700 | 5430 | |||

BA MY70/870-U(BK) | 70 | 63 | 62 | 1120 | 5360 | 3980 | 6030 | |||

BA MY80/870-U(BK) | 80 | 72 | 71 | 1280 | 5960 | 4250 | 6630 | |||

BA MY90/870-U(BK) | 80 | 80 | 79 | 1280 | 5960 | 4520 | 6630 | |||

BA MY100/870-U(BK) | 80 | 89 | 88 | 1280 | 5960 | 4800 | 6630 | |||

1000-U(BK) Plate and Frame Filter Press Technical Parameters | ||||||||||

Technical parameters: working stroke 480, maximum stroke 510, filter plate size length × width × thickness: 1000mm*1000mm*30mm; Hydraulic clamping, automatic pressure maintenance | ||||||||||

Model | Filtration area | Filter plate/filter | Filter cake thickness | Filter chamber volume | Foundation size | Machine weight | Dimensions (mm) | |||

L | W | H | ||||||||

BA M Y32/1000-U(BK) | 32 | 21 | 20 | 30 | 480 | 2390 | 2800 | 3110 | 1270 | 1350 |

BA MY40/1000-U(BK) | 40 | 25 | 24 | 600 | 2630 | 3250 | 3350 | |||

BA MY50/1000-U(BK) | 50 | 31 | 30 | 750 | 2990 | 3550 | 3710 | |||

BA MY60/1000-U(BK) | 60 | 37 | 36 | 900 | 3350 | 3870 | 4070 | |||

BA MY70/1000-U(BK) | 70 | 43 | 42 | 1050 | 3710 | 4200 | 4430 | |||

BA MY80/1000-U(BK) | 80 | 49 | 48 | 1200 | 4070 | 4550 | 4790 | |||

BA MY90/1000-U(BK) | 90 | 55 | 54 | 1350 | 4430 | 4870 | 5150 | |||

BA MY100/1000-U(BK) | 100 | 61 | 60 | 1500 | 4790 | 5200 | 5510 | |||

BA MY110/1000-U(BK) | 110 | 67 | 66 | 1650 | 5150 | 5540 | 5870 | |||

BA MY120/1000-U(BK) | 120 | 76 | 72 | 1800 | 5510 | 5880 | 6230 | |||

Critical Industry Applications

Edible Oil & Food Processing

- Application: Fractionation (Winterization) of Palm Oil/Sunflower Oil, and polishing of Beer/Syrups.

- The Loway Advantage: Our Cast Iron plates can be equipped with steam jackets to maintain temperature control during fractionation. Using filter paper, we effectively remove stearin, waxes, and residual haze, ensuring a crystal-clear final product.

Pharmaceuticals & Biologicals

- Application: Filtration of blood plasma, serums, vaccines, and insulin.

- The Loway Advantage: Manufactured from SS316L Stainless Steel with mirror-polishing (Ra ≤0.4μm). Our sanitary design eliminates dead corners, supports CIP (Clean-In-Place), and strictly complies with GMP/FDA standards to prevent cross-contamination.

Fine Chemicals

- Application: Precious metal catalyst recovery (Palladium/Platinum) and Activated Carbon removal.

- The Loway Advantage: Standard cloth presses let fine carbon particles pass through. Our Plate & Frame design supports High-Density Filter Paper, capturing particles down to 1 micron to recover expensive catalysts and ensure liquid purity.

Petrochemicals

- Application: Dewaxing of lubricating oils and White Oil fractionation.

- The Loway Advantage: Utilizing high-strength Nodular Cast Iron frames, our presses withstand high operating temperatures (>100°C) and high viscosity, maintaining structural integrity where plastic plates would fail.

Why Partner with Loway?

At Loway Equipment, your trust is our asset. We combine strict manufacturing protocols with deep industry know-how to deliver solutions, not just machines.

1. Precision Manufacturing

Zero Leakage Standard: A Plate & Frame press has double the sealing surfaces. Precision is non-negotiable. We CNC mill every sealing face to a flatness of ≤0.1mm, ensuring zero capillary leakage even with thin filter paper.

Premium Materials: Whether it’s Stainless Steel (304/316L) for Pharma or Cast Iron for High-Temp Oil, we use only certified materials to ensure durability.

2. Engineering Expertise

Hands-On Experience: With years of focused engineering, our team possesses deep practical experience. We don’t just supply equipment; we optimize your filtration process based on real-world data.

Lab Support: Not sure which media to use? Send us your slurry. We offer free sample analysis to recommend the exact filter paper or cloth density for your goal.

3. Long-Term Commitment

Reliable Partnership: We stand behind every product. From initial consultation to lifetime spare parts supply, we are dedicated to your success.

Frequently Asked Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is the main difference between "Plate & Frame" and "Recessed Chamber" filter presses?

Recessed Chamber presses are designed for “Dewatering” (making solids dry) and are easier to automate. Plate & Frame presses are designed for “Polishing” (making liquid clear) or for handling materials that require Filter Paper. If your priority is ultra-high filtrate clarity or removing fine activated carbon, choose Plate & Frame.

Q2: Can I use Filter Paper with this machine?

Yes. This is the primary advantage of the Plate & Frame design. The flat backup plate provides perfect support for filter paper or high-density filter pads, allowing for filtration precision down to 1 micron, which filter cloth alone cannot achieve.

Q3: Can you provide a "Steam Jacketed" version for hot filtration?

Yes. For applications like viscous oil, wax, or gelatin filtration, we manufacture Cast Iron plates with hollow internal channels. This allows steam or hot water to circulate through the plates, keeping the product liquid and preventing it from solidifying during filtration.

Q4: Is this machine fully automatic?

Generally, Plate & Frame presses are Manual or Semi-Automatic. Because the frames are separate from the plates and filter paper is delicate, automatic plate shifting is difficult. However, we do equip them with Hydraulic Automatic Closing and pressure maintenance to reduce operator labor.

Q5: Can I change the cake thickness?

Yes. Unlike recessed plates which have a fixed depth, with a Plate & Frame press, you can simply swap out the Hollow Frames for thicker or thinner ones (e.g., changing from 25mm to 40mm) to adjust the cake volume without buying a whole new machine.

Q6: What shall we consider when choosing a plate and frame filter press?

When choosing a plate and frame filter press, consider:

- Material Characteristics: Particle size, solids concentration, filterability

- Production Requirements: Batch size, cycle time, automation needs

- Filtration Goals: Cake dryness, filtrate clarity, throughput

- Operation Environment: Temperature, chemical compatibility, space constraints

- Budget Considerations: Initial investment vs. operational costs

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Filter Cloths

From Monofilament for fast drainage to Multifilament for fine particle capture.

Dewatering Screw Press

Continuous operation for efficient sludge treatment