Automated Filter Press Manufacturer: High-Efficiency Dewatering Solutions for Industrial Sludge

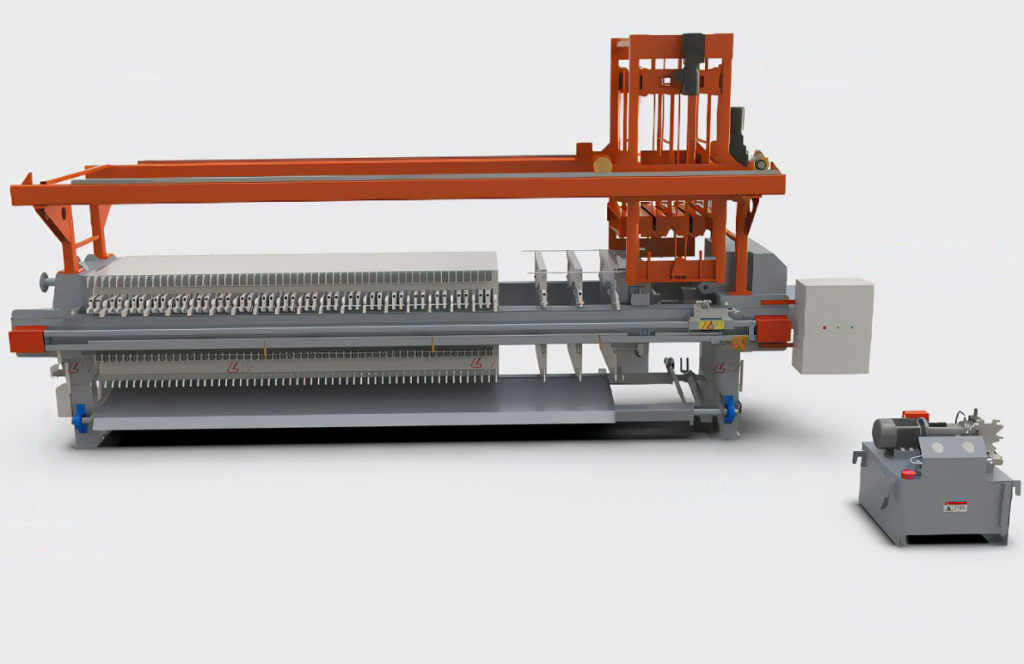

Fully automated filter presses with PLC control, automatic plate shifting, and integrated cake discharge. Built for 24/7 operation in mining, wastewater, and industrial applications.

What Is an Automated Filter Press?

An automated filter press is an advanced solid-liquid separation system designed to minimize manual intervention while maximizing dewatering efficiency. Unlike manual filter presses, automated models feature:

- Automatic plate shifting – No manual labor required for opening/closing

- PLC-controlled operation – Programmable sequences for consistent results

- Integrated discharge systems – Automated cake removal and collection

- Remote monitoring – Real-time performance tracking via HMI touchscreen

Loway’s automated filter presses are engineered for continuous industrial operation, reducing labor costs by up to 60% while improving throughput and cake dryness.

Industry Applications: Proven Performance

Our automated filter presses are preferred choice for solid-liquid separation in diverse industries.

Industry | Key Application | Loway Advantage |

Mining & Metallurgy | Tailings dry stacking, Concentrate dewatering (Copper, Gold, Iron) | Heavy-duty frame design withstands abrasive slurries and 24/7 high-tonnage processing. |

Chemical Processing | Pigments, Dyes, TiO2, Silica, Fertilizer | Corrosion-resistant PP plates and special coatings protect against aggressive acids and alkalis. |

Wastewater Treatment | Municipal sludge, Textile dyeing wastewater, Leather sludge | Significant volume reduction (up to 60-80%) lowers disposal volume and costs drastically. |

New Energy | Lithium carbonate, Battery precursor materials | High-purity filtration with automated washing ensures contamination-free end products. |

Food & Pharma | Starch, Sugar, Antibiotics, Beer mash | FDA-grade filter plates and sanitary structure designs (SS304/316 cladding) available. |

Key Features of Loway Automatic Filter Press

Built for heavy-duty applications, our equipment combines precision engineering with smart automation.

- Intelligent PLC Control System

- Siemens/Schneider Components: Ensures global reliability and ease of replacement.

- Unattended Operation: Program the complete cycle—feeding, filtering, squeezing, blowing, and discharging—from a single HMI panel.

- Remote Monitoring: (Optional) Check system status and diagnostics from your mobile device or control room.

- High-Pressure Membrane Technology

- Operating Pressure: Standard models up to 16 bar (232 psi), with high-pressure options up to 30 bar.

- Secondary Squeezing: Uses water or air to physically compress the filter cake after the feeding cycle, extracting maximum filtrate.

- Result: Drier cakes translate to lower transport fees and reduced landfill tax.

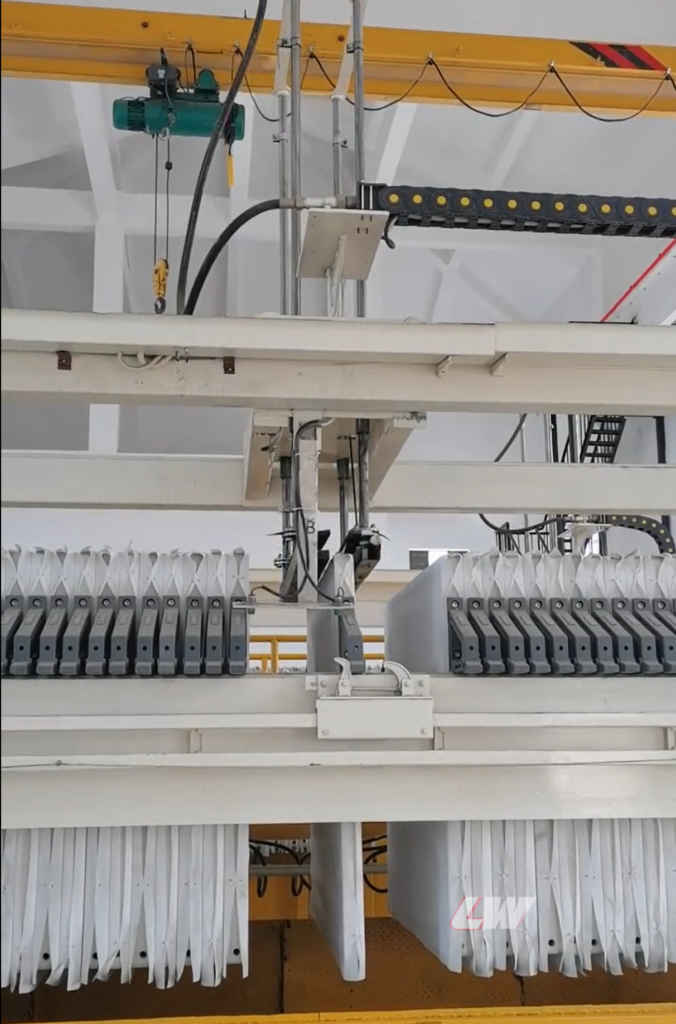

- Automatic Plate Shifting & Discharge

- Fast-Open System: Capable of opening multiple plates simultaneously to reduce cycle time by 30%.

- Vibration Assist: Automatic shaking mechanism ensures sticky filter cakes fall off completely without manual intervention.

- Automatic Cloth Washing System

- Maintain Permeability: High-pressure water jets (up to 50 bar) automatically clean filter cloths between cycles.

- Extended Lifespan: Prevents blinding and prolongs the life of your filter media.

Working Process of Automatic Filter Press

The automatic filter press system consists of multiple interconnected stages, each designed to ensure effective and consistent separation of solids and liquids.

Plate Closing: The hydraulic system applies a pressing force of 0–30 MPa to tightly seal the filter plates.

Slurry Feeding: A high-pressure plunger pump injects slurry into the filter chambers at 0.6–2.0 MPa.

Filtration: Liquid passes through the filter cloth, while solid particles form a filter cake with a typical thickness of 25–50 mm.

Membrane Squeezing (Optional): In membrane filter presses, compressed air or water expands an internal elastic diaphragm to achieve secondary squeezing, significantly lowering moisture content.

Automatic Discharge: A plate shifting system automatically opens the filter plates, allowing cakes to fall off by gravity.

Cloth Cleaning: High-pressure spray systems remove residual particles, maintaining filtration efficiency.

Automation Options & Add-ons of Loway Automatic Filter Press

Automatic Cloth Washing System

Extends filter cloth life by 30-50%

Membrane Squeeze

Improves cake dryness by 10-15%

Automatic Cake Discharge Conveyor

Integrated material handling

Remote SCADA Integration

Monitor multiple units from control room

Explosion-Proof Design

For hazardous environments (ATEX certified)

Technical Specifications

The following table outlines the standard range of our Automated Filter Press systems. Custom configurations are available upon request to meet unique project requirements.

Parameter | Specification Range | Key Consideration |

Filtration Area | 10 m² to 1000 m² | Determines total batch capacity and throughput. |

Plate Size | 630mm, 800mm, 1000mm, 1250mm, 1500mm, 2000mm | Scalable to fit various plant footprints and volumes. |

Operating Pressure | Up to 16 bar (232 psi) | Higher pressure facilitates faster filtration and lower cake moisture. |

Cake Moisture | 15% to 30% (Material Dependent) | Achievable moisture content, critical for disposal cost reduction. |

Cake Thickness | 30-60mm | Material dependent |

Automation Level | Fully Automatic (PLC + HMI) | Ensures consistent, autonomous operation. |

Plate Material | Reinforced Polypropylene (PP), Membrane PP, Cast Iron, Stainless Steel | Selected based on chemical compatibility and temperature. |

Frame Material | Q345B Carbon Steel (Sandblasted + Epoxy Coated) or SS304 Clad | Selected based on industry application. |

Benefits

How Fully Automated Filter Press Solves Your Problems

In modern industrial processing, efficiency determines profitability. Manual filtration is labor-intensive and often yields inconsistent results. Loway’s Automated Filter Press series integrates advanced PLC controls with robust mechanical design to solve your toughest solid-liquid separation challenges.

We don’t just sell machines; we deliver a solution that significantly reduces your Total Cost of Operation (TCO).

- Lower operating cost: Automation reduces labor and human error, optimized cycles improve cake dryness.

- Predictable performance: PLC recipes deliver repeatable cycles for consistent product quality.

- Faster ROI: Higher throughput and reduced waste disposal costs accelerate payback.

- Easier maintenance: Modular plates and rapid cloth access shorten service windows.

- Ensure Safety: Fully enclosed operation protects operators from hazardous slurries and chemical fumes.

- Scalable & OEM ready: Modular design for integration into existing process lines or OEM systems.

Why Choose Automatic Filter Press from Loway Equipment?

Factory-Direct Manufacturer

As a direct filter press manufacturer based in China, we eliminate middleman markups. You get factory-direct pricing without compromising on quality components (hydraulics, motors, electricals).

Custom Engineering

We don’t offer “one-size-fits-all.” Our in-house engineering team analyzes your slurry characteristics (pH, particle size, viscosity) to design the optimal filtration area, pump pressure, and cloth type for your project.

Comprehensive Support

From initial consulting to installation guidance and spare parts supply, Loway supports your project lifecycle.

Frequently Asked Question

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What does “automatic” cover in your filter press?

Automation includes PLC-controlled fill, pressurization, timed filtration, automatic cloth wash/shaker, plate opening and cake discharge—minimizing manual intervention.

Q2: Can you customize plate size and material?

Yes. We offer multiple plate sizes and materials (PP, PS, membrane plates) and tailor designs for chemical resistance and cake release.

Q3: How much labor can I save with an automated filter press?

Most clients report 50-60% reduction in direct labor costs. A manual filter press typically requires 2-3 operators per shift, while an automated system can run with just 1 supervisor monitoring multiple units.

Q4: What's the difference between automatic and semi-automatic filter presses?

Semi-automatic: Requires manual plate opening/closing; automated feeding and pressing only.

Fully automatic: Complete cycle automation including plate shifting, cake discharge, and cloth washing. Zero manual intervention during normal operation.

Q5: Can automated filter presses handle abrasive materials?

Yes. We use reinforced polypropylene plates and high-wear filter cloths rated for mining applications. Expected plate life: 5-8 years; cloth life: 2,000-3,000 cycles with proper maintenance.

Q6: How low can the cake moisture content be with your Membrane Filter Press Automation?

With our advanced Membrane Filter Press Automation, we can typically achieve cake moisture content in the range of 15% to 30%, depending on the specific material and its compressibility. The secondary squeezing phase significantly surpasses the dewatering limits of standard chamber filter presses.

Q7: Can I integrate this with my existing plant automation?

Absolutely. Our PLC systems support Modbus RTU/TCP, Profibus, and Ethernet/IP protocols. We provide integration support to connect with DCS or SCADA systems.

Q8: What is the typical ROI of an Automated Filter Press compared to a manual one?

The return on investment (ROI) is primarily driven by three factors: labor savings, reduced disposal costs, and increased throughput. By automating the entire cycle, you eliminate the need for continuous operator presence, and the consistently lower cake moisture content directly translates to lower costs for transporting and disposing of filter cake. Most industrial operations see a rapid ROI due to these combined efficiencies.

Q9: What maintenance is required for the automatic plate shifting system?

The automatic plate shifting system is designed for minimal maintenance. Key requirements include routine lubrication of the chain and guides, and periodic inspection of the hydraulic system seals. Our smart control system provides predictive maintenance alerts, allowing you to address potential issues before they lead to downtime.

Related Products

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Mobile Filter Press

Portable solutions for temporary sites

Dewatering Screw Press

Continuous operation for efficient sludge treatment