Industry Applications

Precision-Engineered Solid-Liquid Separation for Your Industry

At Loway Equipment, we specialize in solving complex filtration challenges. With over two decades of manufacturing expertise, we have evolved beyond traditional filtration to offer the complete spectrum of dewatering technologies—from Filter Presses and Belt Presses to Screw Presses, Rotary Drum Filters, and Mechanical Bar Screens.

Because we manufacture all major dewatering technologies in-house, our recommendations are unbiased. We analyze your specific sludge profile, flow rates, and operational budget to match you with the most efficient solution—whether that’s high-pressure filtration for dry stacking or continuous separation for biological sludge.

Industries We Serve

Find the specialized solution engineered for your sector’s unique challenges.

Mining & Mineral Processing

The Challenge: Managing massive volumes of abrasive tailings and complying with environmental dry-stacking regulations.

Our Solution: Heavy-duty systems designed for high wear resistance and maximum water recovery.

Key Equipment:

- High-Pressure Membrane Filter Presses: For achieving maximum cake dryness (>85%) in tailings management (Gold, Copper, Iron, Lithium).

- Belt Filter Presses: For high-throughput washing in sand and aggregate plants.

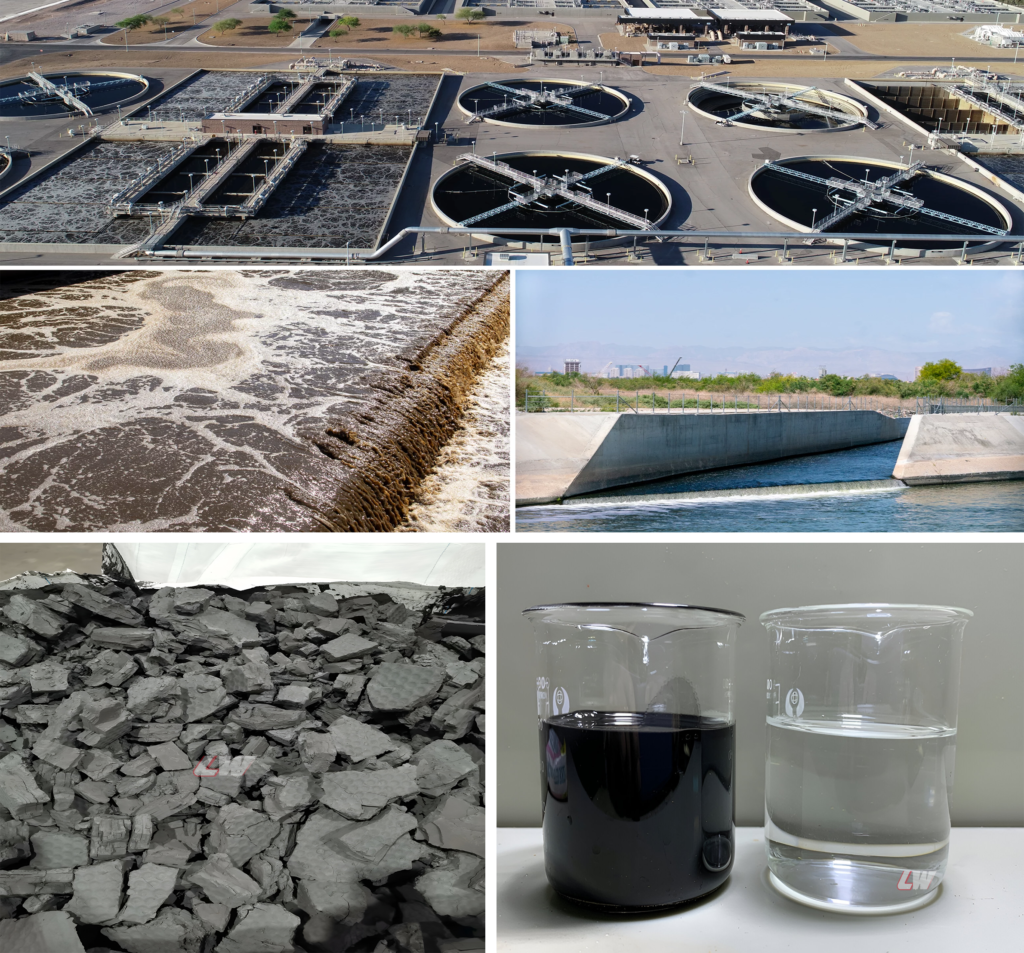

Municipal Wastewater Treatment (WWTP)

The Challenge: Reliable, energy-efficient processing of biological sludge and headworks debris removal.

Our Solution: A complete ecosystem from intake screening to final sludge disposal.

Key Equipment:

- Mechanical Bar Screens & Drum Filters: For effective headworks pre-treatment and debris removal.

- Belt Filter Presses: For consistent, large-volume municipal sludge dewatering.

- Multi-Disc Screw Presses: For automated, low-energy thickening and dewatering.

Food, Beverage & Pharmaceutical

The Challenge: Handling organic, oily, or sticky sludge while maintaining strict hygiene (FDA/GMP) standards.

Our Solution: Sanitary-grade equipment utilizing Stainless Steel (304/316L) and enclosed designs to prevent odor and contamination.

Key Equipment:

- Multi-Disc Screw Presses: Ideal for DAF sludge and oily food waste (clog-free design).

- Rotary Drum Filters: For efficient liquid-solid separation in food processing lines.

Chemical & Industrial Manufacturing

The Challenge: Dewatering hazardous, corrosive, or high-temperature slurries safely.

Our Solution: Customized systems featuring corrosion-resistant materials (PVDF, PP) and explosion-proof components.

Key Equipment:

- Recessed Chamber Filter Presses: For chemical synthesis and pigment production.

- Specialized Screw Presses: For petrochemical and refinery oily sludge.

Aquaculture (RAS) & Water Intakes

Primary Challenge: Removing fine suspended solids to protect sensitive biological systems or downstream equipment.

Our Solution: Precision Rotary Drum Filters and Fine Screens for Critical Pre-Treatment and Water Clarity Management.

Key Equipment:

-

Rotary Drum Filter: removes fine suspended solids (down to ~100 microns) from large water flows, protecting pumps and biological reactors.

-

Fine Mechanical Bar Screen: removes smaller solids, fibers, and debris from water intakes, preventing blockages in downstream equipment.

Textile & Dyeing

Primary Challenge: Treating wastewater with high COD, variable pH, and complex dyes.

Our Solution: Chemical-Resistant Filter Presses engineered to handle aggressive sludge and produce a dry cake for disposal.

Key Equipment: Membrane Filter Presses: mechanically squeezing out maximum filtrate to produce an exceptionally dry, compact cake for cost-effective disposal.

Technology Comparison: Finding Your Ideal Match

Not sure which technology suits your process? Here is a quick comparison of our core dewatering technologies based on key performance indicators.

|

Feature |

Filter Press (Chamber/Membrane) |

Multi-Disc Screw Press |

Belt Filter Press |

|

Best For |

Inorganic, Mineral, Chemical Sludge |

Oily, Biological, Food Sludge |

Large Volume Municipal/Paper/Sand |

|

Cake Dryness |

Highest (Max solids content) |

Medium (15-25% DS) |

Medium (18-25% DS) |

|

Operation |

Batch Cycle (Intermittent) |

Continuous (24/7 Automated) |

Continuous |

|

Footprint |

Large |

Compact |

Medium |

|

Maintenance |

Routine Cloth Washing |

Very Low (Self-Cleaning) |

Regular Belt Washing |

|

Core Value |

Lowest disposal/hauling costs due to dry cake. |

“Set and forget” automation for sticky sludge. |

High throughput stability for massive flows. |

This is a general guide. Please contact Loway engineers for a detailed calculation based on your specific slurry analysis.

We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services.

Please count on Loway’s deep industry and applications knowledge for the right engineered filtration solution to meet your needs.

We look forward to working with your team.

Industries & Technologies

Why Partners Choose LOWAY

We are more than just an equipment supplier; we are your engineering partner in fluid management.

- Broad Technology Portfolio

We don’t force a Filter Press on an application that needs a Screw Press. We recommend the right technology for your specific sludge characteristics.

- Factory-Direct Value

By eliminating middlemen, we offer competitive pricing on equipment and spare parts without compromising on quality.

- Custom Engineering

From skid-mounted mobile units to fully automated PLC-integrated systems, we build to your site’s specifications.

The Loway Advantage: From Design to Commissioning

In-Depth Consultation & Lab Testing:

Don’t guess. Send us a 2-liter sludge sample. Our lab performs filtration tests to generate real data, ensuring the equipment we quote will perform as promised.

Custom Engineering (OEM/ODM):

We tailor every aspect—from PLC brands (Siemens/Schneider) to skid-mounted integration—fitting your facility’s layout and voltage requirements.

Transparent Manufacturing:

As a direct factory, we provide weekly production updates (photos/videos) so you can monitor your equipment’s progress before it even ships.

Global Support:

We provide detailed installation manuals, video guides, and remote commissioning support. On-site engineer dispatch is available for complex startups.

Frequently Asked Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How do I know which dewatering technology is best for my application?

The choice depends primarily on your sludge type and target dryness.

- Filter Presses are best for inorganic sludge (mining, stone, chemical) where maximum cake dryness is required.

- Screw Presses are ideal for organic, oily, or sticky sludge (food, biological wastewater) requiring continuous, automated operation.

- Belt Presses suit large-volume applications where throughput speed is more important than extreme dryness.

We recommend sending us a sludge sample for a free lab analysis to determine the precise fit.

Q2: Can LOWAY customize equipment to fit my existing facility?

Yes. As a direct manufacturer, we offer full OEM/ODM services. We can customize machine dimensions to fit tight spaces, integrate specific PLC brands (Siemens, Schneider, Allen-Bradley), and adapt piping layouts. We also provide skid-mounted systems that are pre-wired and pre-piped for “plug-and-play” installation.

Q3: Do you provide installation and commissioning support internationally?

Absolutely. We support global clients through detailed video tutorials, installation manuals, and 24/7 remote technical assistance. For complex projects, we can dispatch engineers to your site for installation guidance, commissioning, and operator training.

Q4: What information do I need to provide to get a quote?

To provide an accurate proposal, please share:

- The type of sludge/wastewater source.

- Your hourly processing capacity (m³/h) or solids load (kg/h).

- The solid content (%) of your incoming slurry.

- Your desired cake moisture content.

If you are unsure, our engineers can help you estimate these parameters.