While the material of the filter cloth is crucial, the installation structure also plays a significant role in determining the filtration system’s efficiency. The way a filter cloth is installed can directly affect the sealing performance and the ease of maintenance and replacement.

Sleeve Filter Cloth

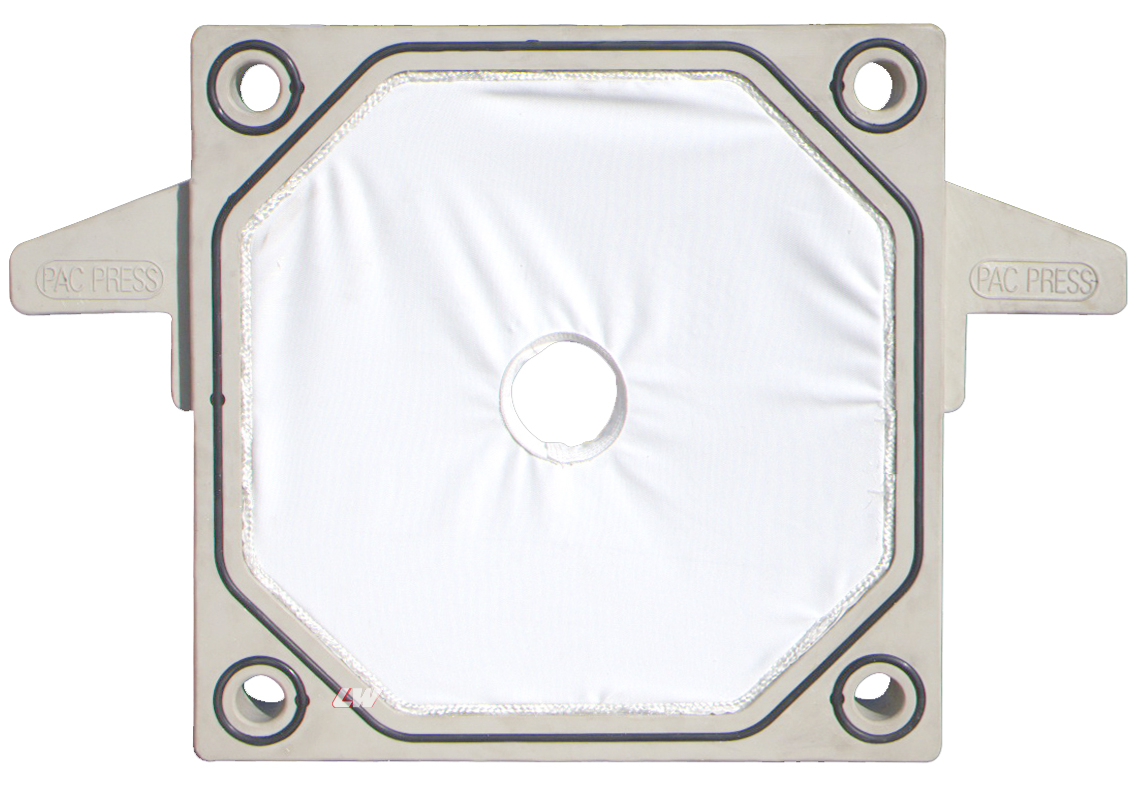

Sleeve filter cloths are characterized by a one-piece cartridge weave that completely wraps around the filter plate. This design ensures a seamless, 360° sealing capability that eliminates any dead angles, thereby preventing side leakage during the filtration process.

The primary benefit of sleeve filter cloth is its quick disassembly feature. In practical terms, this means that replacing a single filter plate takes less than three minutes, significantly reducing downtime and maintenance labor. Its secure wrapping around shaped filter panels, such as diamond-shaped or round plate frames, further ensures a tight seal and consistent performance.

Due to its robust design and ease of maintenance, sleeve filter cloths are especially well-suited for modern filtration systems where time efficiency and reliability are paramount. Industries requiring frequent maintenance and high operational throughput greatly benefit from this installation structure.

Drape Filter Cloth

Drape filter cloth offers a distinctive design with a free-falling bottom that does not rely on fixing clips. This design innovation allows the cloth to adapt to the shape of the filter press more naturally, ensuring a closer fit to the deflector groove.

One of the standout advantages of drape filter cloth is its ability to enhance drainage speed—up to a 30% increase compared to traditional designs. This faster drainage is achieved without compromising the cloth’s integrity, making it ideal for retrofitting older filter presses. Additionally, the design supports online cleaning without the need for dismantling, which further simplifies maintenance procedures.

Embedded Filter Cloth

Embedded filter cloths are engineered with pre-installed TPU reinforcement along the edges, ensuring added strength and durability. Their matching dovetail design for filter plates enhances the overall stability of the system. Additionally, some variants offer optional conductive fiber weaves for improved safety in certain environments.

The main advantage of embedded filter cloth is its excellent displacement resistance. With ultra-high pressure tolerance and 50% higher stability than traditional designs, these cloths are particularly suited for applications where high pressure is a routine challenge. The anti-static safety certification is an added benefit, especially in scenarios involving chemical, flammable, or explosive materials.

Beyond the material properties, the installation structure significantly impacts the overall effectiveness of the filtration system. Sleeve filter cloths provide a reliable, leak-proof solution with quick maintenance turnaround. Drape filter cloths enhance drainage and retrofit flexibility, while embedded filter cloths excel in high-pressure and safety-critical environments. Understanding these differences can help you choose the best configuration to meet your operational challenges.

The material and installation structure of filter press cloths play a pivotal role in the efficiency and longevity of your filtration system. From monofilament to polyester, each material offers unique advantages that can be harnessed to optimize performance across various industrial applications. Coupled with innovative installation designs such as sleeve, drape, and embedded filter cloths, the potential for enhanced sealing, easier maintenance, and improved filtration precision is immense.

Ready to Optimize Your Filtration Process?

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges. From process assessment to custom configurations, we’re here to help you achieve maximum efficiency and product quality.

filter press price | sludge dewatering equipment supplier | filter press manufacturer| dewatering screw press | belt filter press | wastewater treatment equipments| wastewater treatment plants

schedule a consultation with our filtration experts