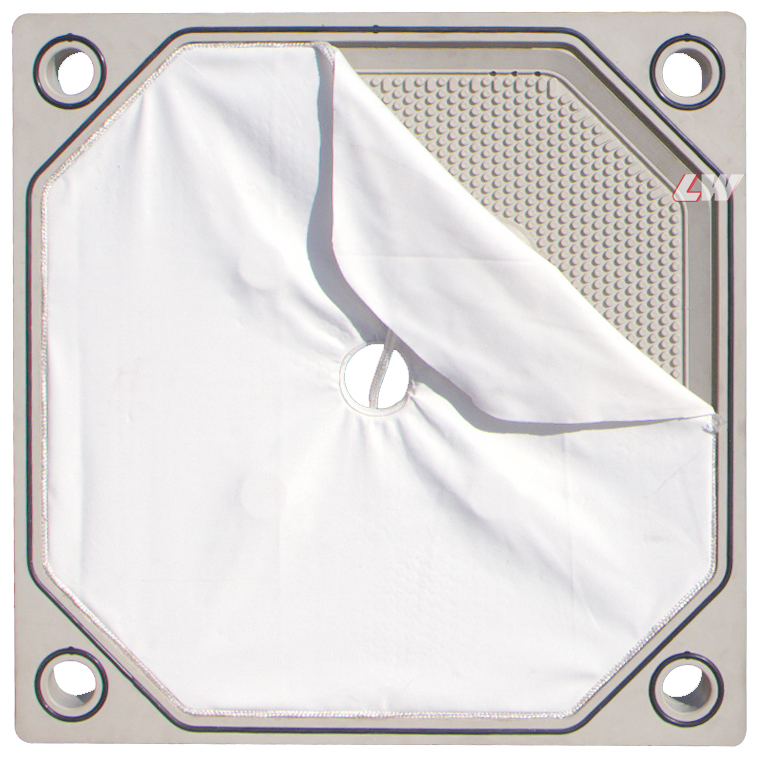

Bonded Filter Cloth

Bonded filter cloth is a type of filter media that uses advanced adhesive bonding to ensure high filtration efficiency, minimal leakage, and improved operational safety.

Pressure bonded filter cloth is an advanced filtration medium designed for critical applications where zero leakage is essential. These specialized filter cloths utilize high-pressure bonding technology to create seamless, reliable filtration surfaces that prevent even the smallest particles from escaping the filtration process.

Features and Benefits

✅Zero Leakage Filtration: Ensures complete containment of all materials during filtration processes

✅Improved Operational Safety: Minimizes release of toxic, harmful, flammable, or explosive volatile gases

✅Reduced Material Loss: Preserves valuable materials that would otherwise be lost through conventional filter media

✅Enhanced Process Efficiency: Creates optimal operating conditions with consistent filtration performance

✅Extended Service Life: Superior durability compared to traditional filter cloths

✅Chemical Resistance: Withstands exposure to aggressive chemicals and solvents

✅Temperature Stability: Maintains structural integrity across a wide range of

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Material Composition | Polypropylene, Polyester, PTFE, Nylon, and custom blends |

| Thickness | 0.5mm – 3.0mm |

| Weight | 250 – 800 g/m² |

| Temperature Resistance | -20°C to 180°C (depending on material) |

| Pressure Differential Capacity | Up to 6 bar |

| pH Resistance | 1-14 (material dependent) |

| Particle Retention | 1-100 microns |

| Permeability | 5-500 L/m²/min at 200Pa |

Key Technology Behind Loway Automated Filter Presses

Pressure Filtration Mechanics

Automated filter presses use mechanical pressure to force liquids through filter media, typically filter cloths, while retaining solids. The pressure squeezes liquid from the slurry, creating increasingly dry solid cakes.

Automation Control Systems

Modern filter presses utilize sophisticated PLCs that control the entire operation from feeding to cake discharge. These systems monitor pressure, flow rates, and cycle times while making real-time adjustments for optimal performance.

Filter Media Technology

High-performance synthetic filter cloths with precise micron ratings ensure effective solid capture while allowing clear filtrate to pass through. Advanced media options include chemical-resistant materials for aggressive applications.

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Advantages of Using Bonded Filter Cloth

Reducing Precious Material Loss

For industries dealing with expensive or scarce materials, every drop counts. The bonded filter cloth ensures that no material is wasted, making it an invaluable asset in operations where cost efficiency is crucial. It works like a meticulously designed sieve that captures every bit of the substance, significantly reducing material loss.

Minimizing Risk of Toxic and Flammable Gas Leakage

Safety is always a top priority in industrial operations. Bonded filter cloth plays a pivotal role in preventing the leakage of hazardous gases—be it toxic, flammable, or explosive volatile substances. This not only protects the workforce but also mitigates environmental risks, creating a safer working environment overall.

Enhancing Operational Conditions

Improved filtration directly translates to better operational conditions. By ensuring that the filtering process is both efficient and reliable, bonded filter cloth contributes to smoother production lines and fewer interruptions. This level of consistency can lead to enhanced productivity and lower maintenance costs over time.

Key Manufacturing Process of Bonded Filter Cloth

- Material Selection: Premium-grade fibers are carefully selected based on application requirements.

- Precision Weaving: Advanced weaving techniques create the base cloth structure.

- Pre-treatment: Specialized treatment to prepare the fabric for the pressure bonding process.

- High-Pressure Bonding: Application of precisely controlled pressure and heat to create molecular bonds between fibers.

- Edge Sealing: Advanced techniques to ensure edge integrity and prevent bypass leakage.

- Quality Inspection: Rigorous testing for permeability, strength, and zero-leak performance.

- Custom Finishing: Application of specific treatments based on end-use requirements.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How does the bonding process improve filtration?

The bonding process involves applying a high-quality adhesive to securely join the fibers of the filter cloth. This creates a uniform and robust surface that significantly reduces leakage and improves overall filtration efficiency.

Q2: What industries can benefit from using bonded filter cloth?

Industries such as chemical processing, pharmaceuticals, food production, and heavy industrial operations benefit greatly from the enhanced efficiency and safety provided by bonded filter cloth.

Q3: How do I maintain bonded filter cloth for long-term use?

Regular inspections, proper installation, and routine cleaning are essential for maintaining the efficiency of bonded filter cloth. Addressing any minor issues early can prevent major disruptions.

Q4: How does pressure bonded filter cloth differ from conventional filter cloth?

Pressure bonded filter cloth uses a specialized manufacturing process that creates molecular bonds between fibers, eliminating the microscopic gaps present in conventional filter cloths. This results in zero leakage filtration while maintaining optimal flow rates.

Q5: How long does pressure bonded filter cloth typically last?

While service life depends on application conditions, pressure bonded filter cloths generally last 30-50% longer than conventional alternatives due to their superior structural integrity and resistance to degradation.

Q6: Can pressure bonded filter cloth be customized for specific applications?

Yes, we offer customization options including specific material compositions, permeability ratings, surface treatments, and dimensional specifications to meet precise application requirements.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.