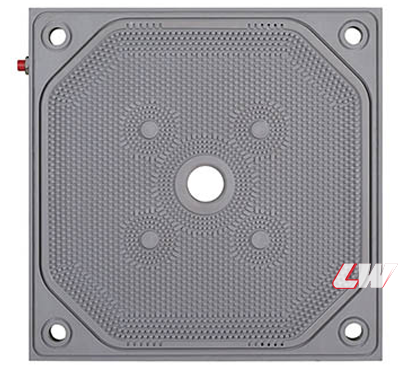

Embedded Filter Plates

Embedded filter plates are specially designed filtration components used in pressure filtration systems such as plate and frame filter presses. These innovative plates feature a unique design that allows them to be embedded or fixed within a frame, working together with other filter plates to create filtration chambers for efficient solid-liquid separation.

Key Features of Embedded Filter Plates

✅Structural Design

- Embedded Structure: Designed to be securely fitted into a fixed frame or plate assembly, forming sealed filtration chambers

- Sealing Edges: Features specialized sealing grooves or gaskets to prevent liquid leakage between plates during high-pressure operations

- Reinforced Support: Includes reinforcement ribs or support structures to withstand pressure during high-pressure filtration processes

- Fish-tail Grooves: Precision CNC-machined fish-tail grooves around the perimeter with dual channels for enhanced sealing

✅Material Composition

- Metals: Stainless steel, aluminum alloys – ideal for corrosion-resistant and high-temperature applications

- Plastics: Polypropylene (PP), PVC – suitable for applications with moderate chemical properties

- Ceramics: For extreme temperature environments and highly corrosive conditions

- High-Strength Polypropylene: One-piece molded construction for durability and chemical resistance

✅Filtration System Integration

- Corner Configuration: Three corners serve as liquid outlet holes while one corner functions as an inlet diagonal hole

- Inlet Connection: The inlet diagonal hole connects with support holes in the plate’s recessed wall

- Filter Cloth Integration: Recessed bottom surface features a circular embedded filter cloth component groove

- Optimized Flow Design: The recessed bottom surface is positioned lower than the inlet support holes

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | High-strength polypropylene, stainless steel, or custom materials |

| Operating Temperature | -10°C to 120°C (material dependent) |

| Maximum Operating Pressure | Up to 1.6MPa (depending on model) |

| Filter Area | 0.5m² to 2.0m² per plate (model dependent) |

| Plate Thickness | 25mm to 50mm |

| Standard Sizes | 500×500mm, 630×630mm, 800×800mm, 1000×1000mm, 1250×1250mm, 1500×1500mm |

| Filtration Precision | 1-100 microns (depending on filter cloth selection) |

| Service Life | 3-5 years under normal operating conditions |

Key Technology Behind Loway Automated Filter Presses

Pressure Filtration Mechanics

Automated filter presses use mechanical pressure to force liquids through filter media, typically filter cloths, while retaining solids. The pressure squeezes liquid from the slurry, creating increasingly dry solid cakes.

Automation Control Systems

Modern filter presses utilize sophisticated PLCs that control the entire operation from feeding to cake discharge. These systems monitor pressure, flow rates, and cycle times while making real-time adjustments for optimal performance.

Filter Media Technology

High-performance synthetic filter cloths with precise micron ratings ensure effective solid capture while allowing clear filtrate to pass through. Advanced media options include chemical-resistant materials for aggressive applications.

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Advanced Technology

Closed System Design

Prevents evaporation of volatile substances and contamination

Precision Engineering

CNC-machined components ensure exact fit and optimal sealing

Integrated Filter Cloth System

The filter cloth fits precisely into engineered grooves for leak-free operation

Optimized Flow Dynamics

Specially designed inlet and outlet configurations maximize filtration efficiency

Key Advantages

- High Filtration Efficiency: Forms sealed filtration chambers for improved performance.

- Automation-Friendly: Embedded design facilitates automated operations, reducing manual labor.

- Customizable: Size, shape, and material can be customized for specific filtration requirements.

- Corrosion Resistance: Suitable for pesticides, chemicals, strong acids, strong alkalis, and other corrosive or volatile industries.

- One-Piece Construction: High-strength polypropylene molded in one piece for durability.

- Leak-Free Operation: Advanced sealing system prevents leakage under pressure.

- Extended Service Life: Durable construction ensures long operational life.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is an Embedded Filter Plate?

An embedded filter plate is a specially designed filter element integrated into a fixed frame to form a sealed filtration chamber. It enables efficient solid–liquid separation in high-pressure filtering systems.

Q2: Which materials are used in manufacturing these filter plates?

Our filter plates are available in various materials, including stainless steel, aluminum alloy, high-grade plastics (PP, PVC), and ceramics, each chosen based on the specific application and environmental requirements.

Q3: How does the embedded filter plate work?

The process begins with feeding the liquid into the sealed chamber, where it passes through a filter media to trap solids. The plate may then apply additional pressure to form a dense filter cake, which is subsequently removed after the filtration process.

Q4: What industries benefit from using embedded filter plates?

They are widely used in the chemical, food and beverage, pharmaceutical, environmental, petrochemical, and metallurgical industries, among others, where efficient and reliable filtration is critical.

Q5: What are the advantages of using an embedded filter plate?

The advantages include high filtration efficiency, the ability to integrate into automated systems, customizable design options, and robust performance under high pressure and corrosive conditions.

Q6: Can embedded filter plates handle corrosive materials?

Yes, embedded filter plates are specifically designed to handle corrosive materials. Polypropylene plates are highly resistant to most acids, bases, and chemical solvents, while stainless steel versions offer excellent resistance to high-temperature corrosive environments.

Q7: Can embedded filter plates be customized for specific applications?

Yes, embedded filter plates can be customized in terms of size, material, thickness, and configuration to meet specific filtration requirements. Custom designs can accommodate unique process conditions, space constraints, or special handling needs.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.