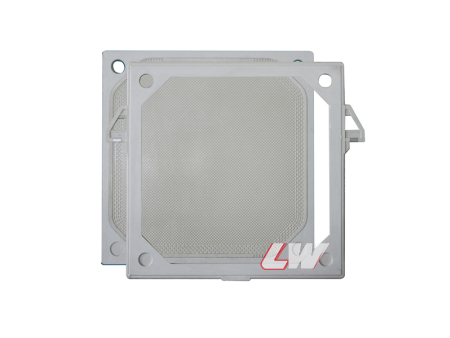

Plate and Frame Filter Plates

Plate and frame filter plates are essential components in industrial filtration systems, enabling efficient separation of solids and liquids in demanding environments. Widely used across oil, chemical, textile, metallurgy, food processing, pharmaceuticals, mining, and environmental protection industries, these plates excel in processing complex suspensions while ensuring operational reliability and longevity.

Key Features & Advantages

✅Non-Toxic & Odorless Food-Grade Materials:

Manufactured with food-safe materials, our filter plates are ideal for applications where contamination is not an option.

✅Excellent Chemical Resistance:

With superior resistance to both acid and alkali corrosion, these plates are perfect for harsh chemical environments.

✅High Abrasion & Impact Resistance:

Designed for longevity, the filter plates offer exceptional durability against wear and tear.

✅High-Temperature Performance:

Capable of operating in high-temperature environments up to 80-120°C (with fiberglass options for enhanced heat resistance).

✅High-Pressure Endurance:

Engineered to maintain structural integrity even under high-pressure conditions.

✅Lightweight & Low Friction:

Their lightweight design combined with a low friction coefficient minimizes mechanical stress and energy consumption.

✅Superior Sealing Performance:

Optimized to prevent leaks, ensuring consistent and effective filtration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Polypropylene, Glass fiber reinforced polymers |

| Temperature resistance | 80-120°C (varies by material) |

| Chemical resistance | Acids, alkalis, corrosive environments |

| Plate sizes | Multiple dimensions available |

| Operating pressure | Up to 16 bar (customizable) |

| Surface finish | Smooth, textured options for different applications |

| Sealing method | Compression gasket, integrated sealing |

Material Technology

Our filter plates are manufactured using advanced materials technology:

- Polypropylene plates: Excellent chemical resistance and durability

- Glass fiber reinforced plates: Superior temperature resistance (up to 120°C)

- HDPE options: For specific application requirements

- Special polymer blends: For enhanced performance characteristics

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Key Process & Technology

Our advanced production process seamlessly blends traditional craftsmanship with modern engineering technologies

Material Selection

We choose only the highest-grade, food-safe, non-toxic materials to ensure safety and compliance with stringent industry standards.

Precision Machining

Each filter plate is precisely manufactured to guarantee a perfect fit and optimal sealing, enhancing filtration performance.

Advanced Coating Technology

Specialized coatings are applied to boost corrosion resistance and ensure longevity, even under aggressive chemical and temperature conditions.

Rigorous Quality Control

Every plate undergoes strict testing protocols to confirm its durability, pressure resistance, and overall performance before it reaches your facility.

Technical Parameters

- Operating Temperature: Up to 80-120°C (with fiberglass variants available for superior high-temperature performance).

- Pressure Resistance: Engineered to perform reliably under high-pressure conditions common in industrial filtration processes.

- Material Specifications: Constructed from non-toxic, odorless, food-grade materials with enhanced resistance to chemicals and abrasion.

- Design Efficiency: Lightweight construction combined with excellent sealing and low friction performance ensures energy efficiency and long service life.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How do I choose between PP and glass fiber filter plates?

PP Plates: Ideal for moderate temperatures (<80°C) and general chemical resistance.

Glass Fiber Plates: Best for high-heat (up to 120°C) and high-pressure environments.

Q2: What industries benefit from using these filter plates?

Our plate and frame filter plates are widely used in industries such as oil, chemical, textile, metallurgy, food, pharmaceuticals, mining, and environmental protection, where efficient suspension filtration is crucial.

Q3: How do I choose the right filter plate for my application?

Consider your specific operating conditions, such as temperature, pressure, and chemical exposure. Our expert team is available to help you select a solution that perfectly fits your process requirements.

Q4: What makes these filter plates superior?

Their non-toxic, food-grade construction, combined with high resistance to corrosion, abrasion, and high pressure, ensures both safety and durability. Additionally, their lightweight design and excellent sealing properties help reduce operational costs and downtime.

Q5: Can filter plates be customized for specific applications?

Yes, we offer customization services including size, material composition, and design features to meet unique filtration requirements.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.