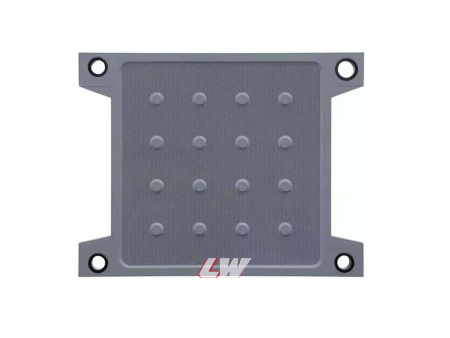

Upper Feed Diaphragm Plates

Our upper feed diaphragm plates are uniquely designed to optimize the filtration process. By allowing liquid to enter from the top, these plates ensure an even distribution of feed, reducing localized pressure on the filtration medium. Ideal for industries such as chemicals, food & beverage, pharmaceuticals, and environmental applications, they are engineered to deliver superior dewatering performance while maintaining ease of maintenance and long-term durability.

Key Features

✅Innovative Design

- Top-Entry Feeding System: Liquid enters from the top of the diaphragm plate, promoting even distribution and reducing localized pressure on the filter media

- Flexible Membrane Structure: The core component is an elastic membrane, typically made of rubber or similar flexible materials, that deforms under pressure to optimize solid-liquid separation

- Reinforced Framework: Enhanced with a strengthening frame that provides additional structural integrity and stability during high-pressure operations

✅Material Excellence

- Membrane Materials: Constructed with chemical-resistant and high-temperature tolerant rubber compounds including natural rubber, nitrile rubber, or EPDM rubber

- Frame Construction: Typically manufactured from stainless steel or other corrosion-resistant materials to ensure durability in harsh environments

- Customizable Options: Available in various materials to match specific industry requirements and chemical compatibility needs

✅Performance Benefits

- Superior Efficiency: Membrane pressing significantly increases the dewatering rate of solid particles

- Uniform Distribution: Even liquid distribution across the filter media reduces localized wear and extends operational life

- Maintenance-Friendly: Designed for easy disassembly and cleaning

- Exceptional Durability: High-quality materials and structural design ensure reliability and longevity

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Plate Size | 250mm × 250mm to 2000mm × 2000mm |

| Operating Pressure | 0.6-1.6MPa |

| Temperature Resistance | Up to 120°C (depending on membrane material) |

| Filtration Precision | 0.5-100 microns |

| Membrane Thickness | 2-5mm |

| Material Options | PP, PVDF, Stainless Steel, Various Rubber Compounds |

| Service Life | 3-5 years under normal operating conditions |

Get a Quote

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges.

Request Instant Quote

Customized Solution for Your Project

86 189 5282 5752

support@lowayequipment.com

Material Selection & Technology

High-Performance Elastomers

Typically made from chemically resistant and heat-resistant rubbers, such as natural rubber, nitrile rubber, or specialized synthetic elastomers.

Optimized for Harsh Conditions

Selected for their durability and ability to withstand aggressive industrial environments.

Stainless Steel & Corrosion-Resistant Alloys

Ensure structural integrity and longevity even in corrosive media.

Engineered Precision

The frame design is integral to the plate’s overall performance, providing the necessary support during high-pressure operations.

Maintenance and Care

To ensure optimal performance and longevity of upper feed diaphragm plates

- Regularly inspect membranes for signs of wear, cracking, or damage.

- Clean filter media and membranes after each filtration cycle.

- Implement scheduled backwashing routines.

- Store plates properly when not in use to prevent membrane deformation.

- Replace worn membranes promptly to maintain filtration efficiency.

Common Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How does top-feed design improve filtration efficiency?

Gravity-assisted distribution reduces pump energy costs by 15-20% while preventing media clogging.

Q2: What makes upper feed diaphragm plates different from standard filter plates?

Upper feed diaphragm plates feature a top-entry feeding system and flexible membrane that enables additional compression of the filter cake, resulting in higher dewatering efficiency compared to standard plates.

Q3: How often should diaphragm plates be replaced?

Under normal operating conditions, diaphragm plates typically last 3-5 years. However, this can vary depending on the application, operating conditions, and maintenance practices. Regular inspection is recommended to determine replacement timing.

Q4: What cake dryness can be achieved?

85-95% solids content depending on material characteristics and pressure configuration.

Q5: What industries benefit most from upper feed diaphragm plates?

Industries requiring high filtration efficiency, thorough dewatering, and processing of difficult-to-filter materials benefit most, including chemical manufacturing, pharmaceuticals, food processing, and environmental applications.

Q6: What maintenance procedures are critical for extending plate life?

Regular cleaning, proper membrane care, scheduled backwashing, proper storage, and prompt replacement of worn components are essential for maximizing service life.

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.