Industrial Filter Presses for Reliable Dewatering & Filtration

Filter Press Systems Manufacturer |Custom Dewatering Solutions

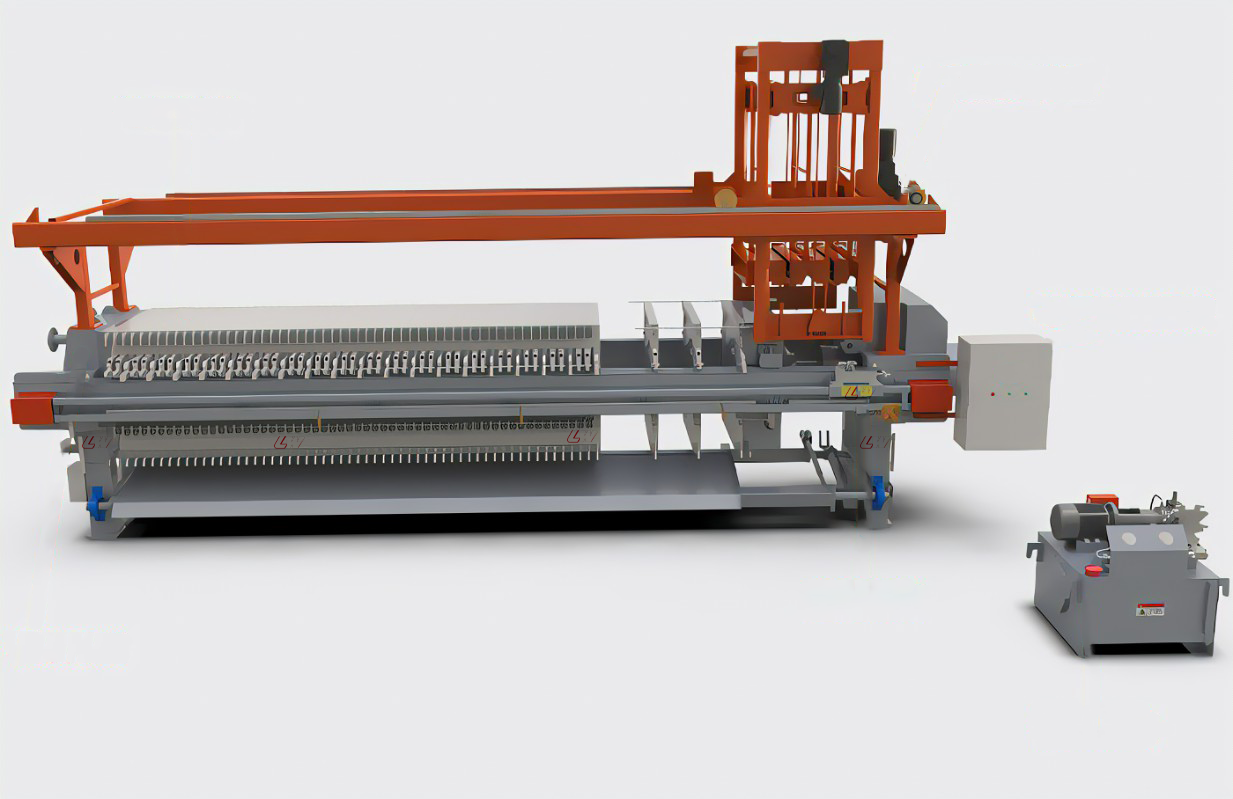

Loway Equipment engineers and manufactures advanced industrial filter press systems designed for critical dewatering, sludge processing, and purification applications.

We deliver end-to-end filtration solutions including plate, membrane and automatic filter presses that reduce cycle times, minimize waste disposal costs, and maximize operational uptime. — ideal for wastewater, mining, chemical, food & oil-recycling applications, trusted globally for superior solid-liquid separation and reliable performance in the most demanding applications.

Core Capabilities

- 25+ Years of Engineering Expertise

- Global Compliance (ASME, CE, ATEX)

- Smart Systems (Automated & IoT Ready)

- Industry-Leading Lead Times

Core Capabilities:

✅ High-Pressure Filtration: Up to 6.0MPa for ultra-dry cakes

✅ Global Compliance: CE, ATEX, ASME, FDA certifications

✅ Smart Technologies: IoT monitoring, AI-driven optimization

✅ Rapid Delivery: 30% faster lead times than industry average

Filter Press Product Range

The industry workhorse. A highly versatile and reliable system for a wide range of standard dewatering applications. Simple operation and robust design.

Drastically cuts downtime. Designed for rapid-cycle batch processes where fast cake discharge and cleaning are critical.

Achieves the highest level of cake dryness. The "squeeze" function significantly reduces residual moisture, ideal for high-value solids or minimizing disposal weight.

Designed for 24/7, lights-out operation. Features automatic plate shifting, cloth washing, and cake discharge to minimize labor costs and maximize throughput.

Offers maximum filtration flexibility. Ideal for processes requiring filter paper or managing variable cake thicknesses and ultra-fine particulates.

Our Customized Filter Press Equipment is designed to meet your specific needs, offering tailored solutions for solid-liquid separation. Whether you require specialized materials, unique configurations, or advanced automation.

We offer a comprehensive range of filter press types, each optimized for specific slurry characteristics and operational goals.

Product Type | Primary Keyword | Key Benefit | Ideal Application |

Membrane Filter Press | Membrane filter press | Superior cake dryness and shorter cycle times via plate inflation. | Fine chemicals, pigments, and high-value recovery. |

Automated Filter Press | Automatic filter press | Full automation of plate shifting, cloth washing, and cake discharge. | High-volume, continuous operations (e.g., mining). |

Plate & Frame Filter Press | Plate and frame filter press | Versatile, cost-effective solution for general solid-liquid separation. | Batch processing, small to medium capacity. |

Recessed Chamber Press | Chamber filter press | Simple, robust design for general sludge dewatering. | Municipal and industrial wastewater treatment. |

Quick Opening Press | Quick opening filter press | Minimal downtime with ≤30-second plate pack opening. | Pharmaceuticals and specialty chemicals requiring rapid turnaround. |

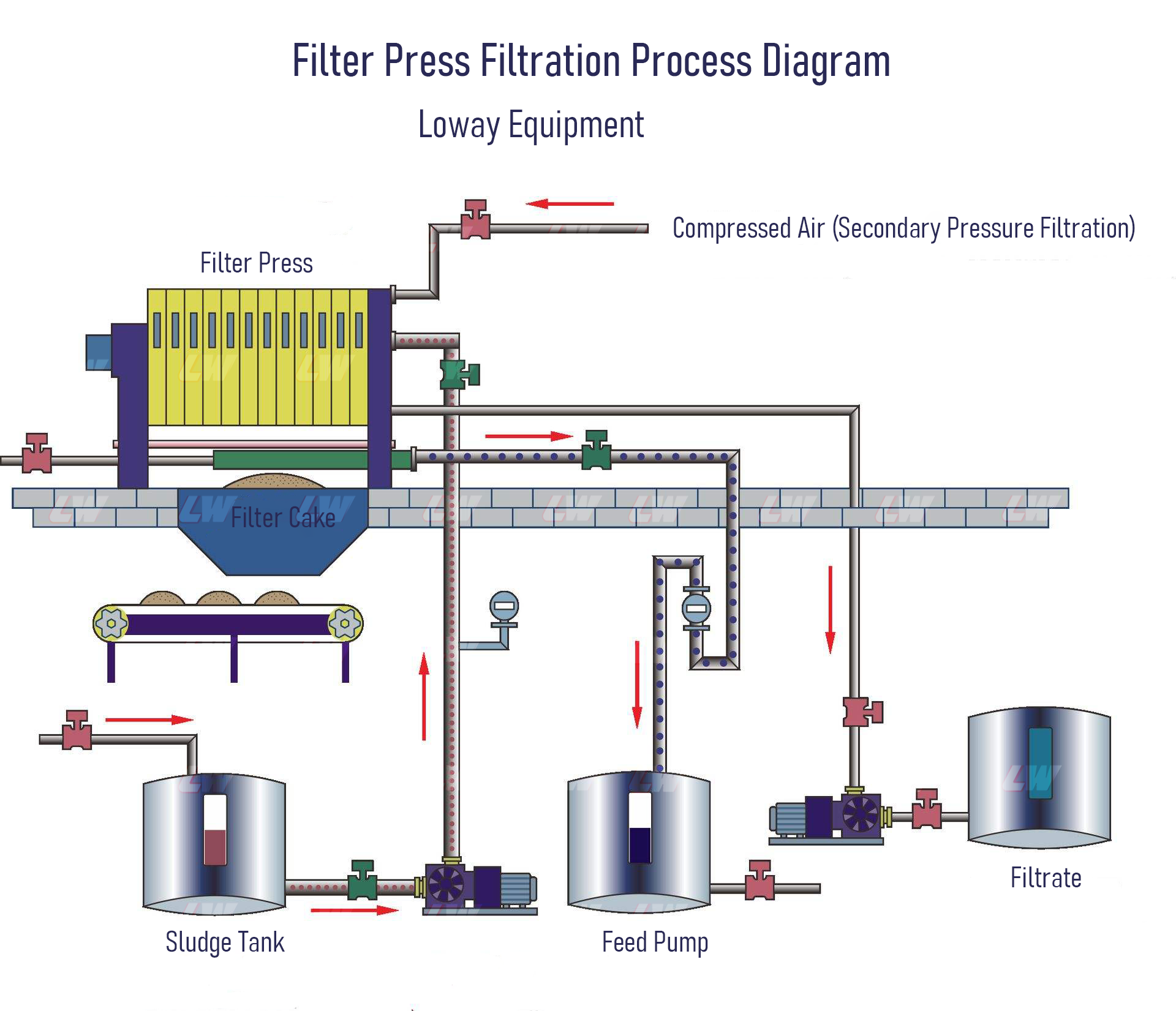

Filter Press Process Cycle (How It Works)

The efficiency of a filter press lies in its simple, robust batch process. While designs vary, the fundamental filter press working principle remains consistent. A complete filtration cycle typically includes these steps:

Step | Process Phase | Description | Optimization Focus |

1 | Plate Closing | The hydraulic system closes the filter plate pack, creating sealed filtration chambers. | Ensuring uniform pressure and leak-free operation. |

2 | Slurry Feeding | The filter press pump injects the slurry into the chambers under high pressure. The liquid (filtrate) passes through the filter press cloth, leaving solids behind. | Consistent feed pressure and flow rate for optimal cake formation. |

3 | Cake Formation & Pressing | Solids accumulate on the cloth, forming the filter cake. For membrane presses, the membrane inflates to mechanically squeeze out residual moisture. | Achieving the lowest possible moisture content (ultra-dry cake). |

4 | Filtrate Discharge | The clean filtrate is collected and discharged from the press. | Monitoring filtrate clarity and flow for process control. |

5 | Cake Discharge | The hydraulic system opens the plate pack, and the filter cake is discharged by gravity or automated plate shifting. | Rapid, clean discharge to minimize cycle time and labor. |

Filter Press Components & Spare Parts

Keep Your System Running at Peak Performance

Available Filter Press Parts:

Filter Press Cloths

– Multiple materials and weave patterns in stock

Filter Press Plates

– Replacement plates for all major brands

Hydraulic Components

– Pumps, cylinders, valves, and seals

Feed Pumps

– Diaphragm and piston pump options

Membrane

– Optional, higher pressing pressure

Automation Upgrades

– Retrofit kits for manual presses

Industry Applications

Proven Solutions Across Global Industries

Wastewater & Sludge Dewatering

Our sludge filter press systems are a benchmark in municipal and industrial filter press wastewater treatment, delivering high solids cake and clear effluent.

Mining & Metallurgy

Robust, heavy-duty presses designed for dewatering mineral concentrates, tailings management, and metal recovery.

Chemical Manufacturing

Specialized systems built with corrosion-resistant materials (e.g., PP, stainless steel) for fine chemicals, pigments, and process intermediates.

Food, Beverage & Pharma

Hygienic, FDA-compliant designs for processes like syrup filtration, brewing, edible oils, and pharmaceutical intermediate purification.

Oil & Gas

Reliable filtration for managing drilling muds, slop oil, and refinery waste streams.

Loway Filtration Excellence

For over 25 years, Loway Equipment has specialized in designing and manufacturing robust filter press systems that solve complex dewatering challenges. Our equipment is built to withstand aggressive industrial environments, ensuring a long operational lifespan and predictable performance.

- Proven performance: Optimized cycle times and >30% cake dryness (spec per model).

- Lower operating cost: Efficient cake washing, automated controls and durable filter cloths.

- Built for industry: Municipal wastewater, mining tailings, chemical plants, food & beverage, transformer oil recycling.

- Service & parts: Global spare parts, cloth replacements, and retrofit services.

- Quality & traceability: Factory QA, inspected hydraulic systems, and documented material certificates.

The Loway Manufacturing Standard

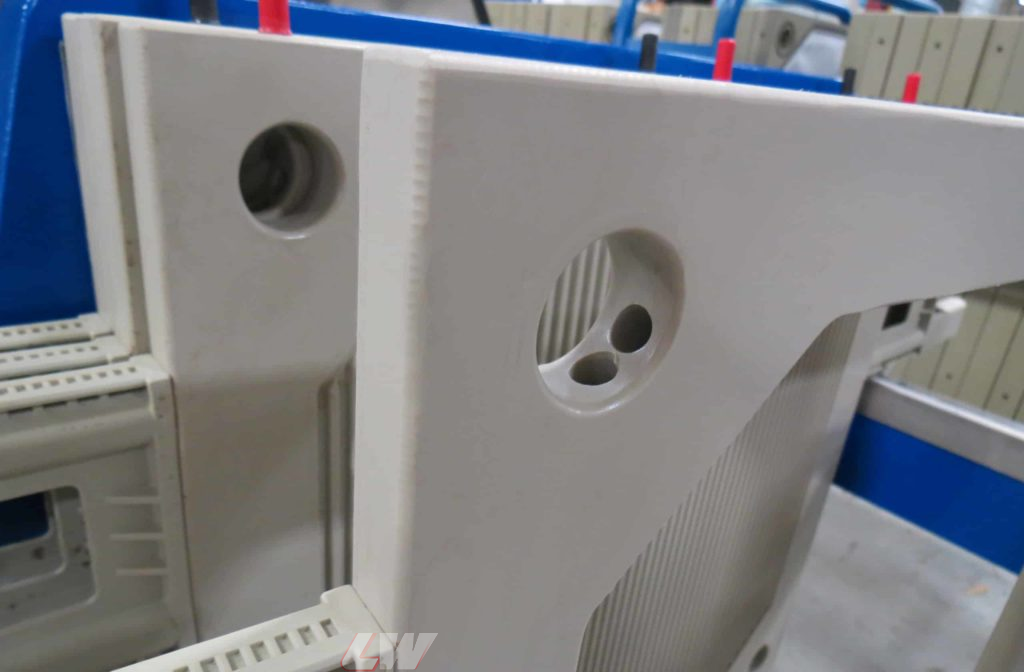

Structural Integrity & Hydraulic Precision

A filter press is only as good as its frame. We utilize Q355B high-tensile steel (or stainless steel options) for our frames, which are robotically welded and stress-relieved to prevent deformation under years of high-pressure cycling.

The Engineering Logic: This rigid structure supports our heavy-duty hydraulic cylinders, allowing for precise pressure control that maintains seal integrity without over-stressing the components.

Optimized Filtration Media & Plate Technology

We don’t believe in “one-size-fits-all” filtration. Our filter plates are molded from 100% virgin Polypropylene (PP) and CNC-machined for precise flatness to eliminate leakage.

The Engineering Logic: We pair these plates with custom-selected filter cloths (PP, Nylon, Polyester, or PVDF). By matching the weave pattern and tension to your specific slurry, we extend cloth life and maximize filtrate clarity.

Intelligent Process Control

Modern filtration requires more than manual operation. Our systems integrate PLC-based automation with real-time pressure monitoring and safety interlocks.

The Engineering Logic: This system actively protects the equipment by preventing over-pressure events and alerts operators to maintenance needs, transforming the press from a passive machine into a controllable process asset.

Validated Quality & System Integration

No equipment leaves our facility based on guesswork. Every unit undergoes a comprehensive static hydraulic pressure test and functional verification before shipment.

The Engineering Logic: We look beyond the press itself. We ensure compatibility with filter press feed pumps, air scouring systems, and cake conveyors, delivering a fully integrated solution that works immediately upon installation.

Engineered for Performance, Built for Trust

Data-Driven Performance

Our advantage is measurable. Compared to industry standards, Loway systems deliver: • Up to 40% Faster Cycle Times through optimized hydraulics and feed. • 30%+ Drier Filter Cakes with our advanced membrane technology. • Extended Plate & Cloth Lifespan (18-36 months) via reinforced composite

We Are Filtration Specialists

We are not just filter press manufacturers; we are your filtration partners. Our team provides expert sizing, process analysis, and pilot testing to ensure the system you buy is the system you need.

Total Lifecycle Support

From installation and training to a global supply of filter press parts, plates, and cloths, we provide 24/7 technical support to keep your operations running.

Not Sure Which System You Need?

Filter Press Selection Guide

Key Factors for Sizing Your System

- Slurry Characteristics

- Feed solids concentration (%)

- Particle size distribution

- Compressibility

- Chemical compatibility requirements

- Throughput Requirements

- Daily/hourly volume to process

- Target cake dryness

- Available batch time windows

- Filter Press Capacity Calculation Basics

Filter Area (m²) = (Slurry Volume × Feed Solids %) / (CakeThickness × Cake Solids % × Number of Cycles per Day)

Common Questions

Most Popular Questions.

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is a Filter Press Equipment?

A filter press is an industrial machine used for solid-liquid separation. It uses high pressure to force a liquid/solid slurry through a series of filter chambers, trapping the solids to form a “filter cake” and allowing the clear liquid (filtrate) to pass.

Q2: How does a filter press work?

The process involves four main steps:

- Filling: Slurry is pumped into the closed filter chambers.

- Filtration: Pressure builds, forcing liquid through the filter cloth.

- Squeezing (Membrane only): Membranes inflate to compress the cake and remove more liquid.

- Discharge: The press opens, and the dry filter cakes are discharged.

Q3: What industries use filter presses?

Filter presses are critical in wastewater treatment, mining, chemical manufacturing, food & beverage, pharmaceuticals, and many more.

Q4: What Types of Filter Presses Equipment Do You Offer?

We provide multiple filter press types:

Plate and Frame Filter Presses

Membrane Filter Presses

Automatic Filter Presses

Manual Filter Presses

Hydraulic Membrane Filter Presses

Q5: What Factors Determine Filter Press Equipment Selection?

Key selection criteria include:

Solid particle characteristics

Liquid viscosity

Required filtration capacity

Operating temperature

Chemical compatibility

Desired cake dryness

Budget constraints

Q6: What Materials Can Be Filtered?

Our filter presses handle diverse materials:

Mineral slurries

Chemical suspensions

Pharmaceutical compounds

Food processing residues

Wastewater sludge

Metal processing waste

Polymer solutions

Q7: What Maintenance Do Filter Presses Equipment Require?

Recommended maintenance includes:

Regular cloth inspection and replacement

Hydraulic system checks

Plate and frame cleaning

Lubrication of moving parts

Pressure system calibration

Annual comprehensive system review

Q8: How Long Do Filter Press Components Last?

Component lifespan varies:

Filter Cloths: 6-24 months

Hydraulic Components: 3-5 years

Stainless Steel Plates: 10-15 years

Seals and Gaskets: 1-2 years

Actual duration depends on:

Operating conditions

Material characteristics

Maintenance quality

Frequency of use

Q9: How Can I Improve Filter Press Equipment Efficiency?

Efficiency improvement strategies:

Regular preventative maintenance

Proper cloth selection

Optimal pressure management

Consistent feed quality

Advanced automation

Periodic performance audits

Q10: What Influences Filter Press Equipment Cost?

Price determinants include:

Equipment size

Material of construction

Automation level

Specialized features

Customization requirements

Production capacity

Q11: How Do I Calculate ROI for a Filter Press Equipment?

ROI calculation considerations:

Reduced waste disposal costs

Increased production efficiency

Lower labor requirements

Improved product quality

Extended equipment lifecycle

Energy consumption reduction

Q12: Do You Provide Installation Support?

Our comprehensive installation services include:

Site assessment

Equipment positioning

System integration

Operational training

Performance testing

Ongoing technical support

Q13: What Warranty do You Offer?

Standard warranty coverage:

12 months parts warranty

6 months workmanship guarantee

Optional extended warranty packages

Comprehensive technical support

Q14: Can Loway Filter Presses Equipment Be Customized?

Customization options:

Plate size modifications

Special material construction

Custom automation levels

Application-specific designs

Unique filtration requirements

Q15: How Long Does Equipment Delivery Take?

Typical delivery timelines:

Standard Models: 4-8 weeks

Customized Solutions: 8-10 weeks

Complex Custom Designs: 10-12 weeks