Lab & Pilot Filter Press: Precision Filtration for R&D and Small-Batch Production

Whether you are scaling up a process or producing high-value small batches, Loway delivers industrial-grade performance in a compact footprint. Reliable data for engineers; robust durability for operators.

Key Capabilities:

- Dual Purpose: Perfect for feasibility studies OR continuous small-batch manufacturing.

- Industrial Build: High-pressure (20 bar) capability and corrosion-resistant materials.

- Plug-and-Play: Integrated skid with pump and control panel.

The Versatile Workhorse for Lab & Pilot Plants

For Research & Scale-Up:

Eliminate the risk of scaling up. The Loway Lab Filter Press replicates the thermodynamics and mechanics of full-scale production, providing Process Engineers with reliable data on cake moisture, washing efficiency, and cycle times.

For Small-Batch Manufacturing:

Not every process requires a massive plant. For high-value, low-volume products—such as pharmaceuticals, essential oils, or precious metal catalysts—this machine is your production line. Built with the same heavy-duty components as our large presses, it ensures 24/7 reliability even in harsh chemical environments.

Key Features

Industrial Power, Bench-Top Footprint

Turnkey Skid Design (Ready to Run)

The Benefit: We integrate the press, Feed Pump (AODD/Screw), and Control Panel onto a mobile stainless steel trolley. Whether you are moving it between lab benches or setting up a small production corner, just connect air/power and start filtering.

Versatile Plate Configurations

The Benefit: Compatible with Recessed Chamber, Membrane Squeeze, and Plate & Frame (for filter paper).

- R&D Use: Test different technologies.

- Production Use: Use Filter Paper for ultra-high clarity polishing of final products.

Corrosion-Resistant Construction

The Benefit: Available with SS304/316L Stainless Steel cladding or full PP structure. This is critical for:

- Hygiene: Food/Pharma GMP compliance.

- Durability: Handling aggressive acids/alkalis without corrosion, ensuring a long service life.

Lab & Pilot Series Specifications

Model | Filter Area (m²) | Cake Vol (L) | Pump Type | Dimensions (LxWxH) |

Lab-200 | 0.1 – 0.5 | 1 – 3 | AODD / Screw | 0.8 x 0.4 x 0.5m |

Lab-320 | 0.5 – 2.0 | 5 – 15 | AODD / Screw | 1.2 x 0.6 x 0.8m |

Lab-450 | 2.0 – 5.0 | 20 – 60 | AODD / Screw | 1.8 x 0.7 x 0.9m |

Lab-630 | 5.0 – 15.0 | 50 – 200 | AODD / Screw | 2.5 x 0.9 x 1.1m |

- Frame Material: Epoxy Coated Carbon Steel (Standard) OR SS304 Clad (Optional).

- Plate Material: PP, Cast Iron, Stainless Steel.

- Operating Pressure: 0.6 MPa – 2.0 MPa.

Core Compents of a Loway Lab Press

Industrial engineering scaled down to bench-top size.

- Heavy-Duty Main Frame (Two Options)

- Carbon Steel (Standard): Fabricated from solid Q235/Q345 Steel. Sandblasted and coated with 3 layers of marine-grade epoxy paint. Ideal for general industrial applications and cost-effective pilot testing.

- Stainless Steel Cladding (Premium): For corrosive environments or hygiene-critical labs (Food/Pharma), we offer SS304 Stainless Steel cladding over the carbon steel structure, ensuring excellent rust resistance and easy cleaning.

- recision Filter Plate Pack

- The Core: Includes a set of Virgin PP, Cast Iron, or Stainless Steel plates.

- Sealing: CNC milled for perfect flatness. CGR (Gasketed) plates are available for zero-leakage filtration of toxic or high-value fluids.

- Integrated Feed Pump

- The Heart: A matched Pneumatic Diaphragm Pump (AODD) or Screw Pump is mounted directly on the skid.

- Control: Includes an air regulator (for AODD) to easily adjust filtration pressure (0-20 bar), giving precise control over the process.

- Hydraulic/Manual Closing System

- Manual Jack: Reliable and simple for smaller units (Lab-200/320).

- Electric Hydraulic: Provides automatic pressure maintenance for larger units (Lab-450/630), essential for long filtration cycles.

- Drip Tray

A built-in tray catches filtrate drips and cake discharge, keeping your lab bench clean and allowing for easy sample recovery.

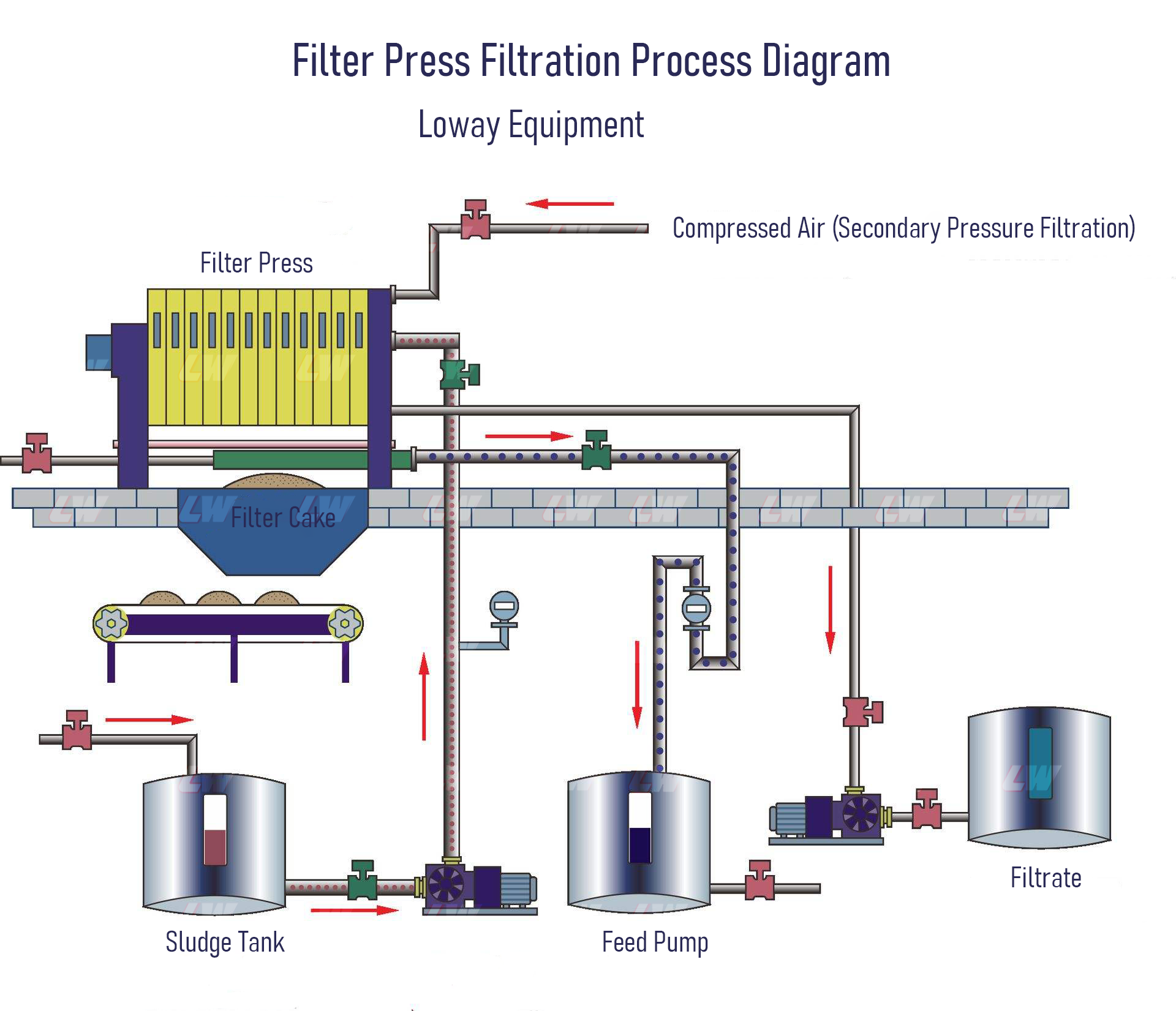

Working Principle

Filter presses operate on the principle of pressure filtration. The process involves:

- Feeding slurry into the chambers formed between filter plates

- Applying pressure to force liquid through filter cloths or membranes

- Retaining solids as filter cakes between the plates

- Releasing pressure and separating plates to remove the cake

Filtration Methods

- Chamber filtration: Utilizes recessed plates to form chambers

- Membrane filtration: Uses flexible membranes for additional compression

- Plate and frame: Alternates frames and plates for enhanced filtration

Industry Applications

Niche Manufacturing (Small Batch)

- Scenario: Production of expensive Active Pharmaceutical Ingredients (APIs), Essential Oil Extraction, or Precious Metal Recovery.

- Why Loway: High-value materials require zero leakage and high purity. Our CGR (Gasketed) plates ensure no product loss.

R&D & Scale-Up

- Scenario: Testing tailings for a new mine or developing a new chemical polymer.

- Why Loway: Generates scalable data (Specific Resistance, Compressibility) to design the main plant correctly.

Pilot Plants

- Scenario: Intermediate testing before full commercialization.

- Why Loway: Rugged construction allows for continuous operation during long-term pilot trials.

Universities & Education

- Scenario: Occasional use for teaching separation principles.

- Why Loway: Simple manual hydraulic operation makes it safe and easy for students to learn.

Manufacturing & Quality

Loway builds lab presses with the same rigor as our 500-ton mining presses.

- CNC Precision: All sealing surfaces are CNC milled to ≤0.1mm tolerance. This is crucial when filtering high-value liquids to prevent dripping.

- High-Pressure Safety: Unlike cheap plastic lab filters, our frames are laser-cut from Solid Carbon Steel (Q345B), tested to withstand 1.5x operating pressure for safety.

Frequently Asked Question

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: How does a lab filter press differ from industrial models?

Lab units are smaller, with lower throughput but higher precision for testing. They often include advanced controls for data collection.

Q2: What is the minimum batch size?

Our smallest unit (Lab-200) has a chamber volume of just 1 Liter. It is perfect for processing very small, high-value samples with minimal waste.

Q3: What’s the typical filtration cycle time of lab filter press?

Ranges from 20 minutes to 2 hours, depending on slurry viscosity and desired cake dryness.

Q4: Can a lab filter press handle high-viscosity liquids?

Yes, but high-viscosity slurries may require higher operating pressures and longer filtration cycles. Pre-treatment with flocculants or heating may improve filtration efficiency.

Q5: What is the difference between a lab filter press and industrial models?

Lab filter presses are smaller, often with manual operation, designed for processing small volumes (0.5-20L). Industrial models handle larger volumes (hundreds or thousands of liters) with higher automation and throughput.

Q6: What filter media is best for fine particle separation?

For particles below 10 microns, multi-layer filter cloths or membranes with 1-5 micron ratings are recommended. Consider depth filtration media for the finest particles.

Q7: Can I filter hot liquids?

Yes. We offer Cast Iron or Stainless Steel plates that can handle temperatures up to 100°C – 150°C, ideal for hot chemical synthesis or oil fractionation.

Related Products

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Filter Plates

From standard Recessed Chamber to high-pressure Membrane and CGR designs.

Dewatering Screw Press

Continuous operation for efficient sludge treatment