Membrane Filter Press

Achieve Lowest Cake Moisture With High-Pressure Secondary Squeezing Technology

Superior Solid-Liquid Separation With Membrane Squeeze Technology

The Membrane Filter Press (also known as a diaphragm filter press or membrane squeeze filter press) represents the pinnacle of solid-liquid separation technology. Engineered for demanding industrial applications, this membrane squeeze technology significantly reduces cake moisture content by 5-15% compared to chamber filter presses, resulting in lower disposal costs, reduced drying time, and improved downstream processing efficiency.

At Loway Equipment, we specialize in delivering robust, high-performance membrane plate filter press solutions that maximize operational efficiency and minimize environmental impact. Our systems are designed for reliability, ease of maintenance, and seamless integration into your existing process line.

Key Features & Benefits

Why Choose Loway Membrane Filter Press?

Your choice of dewatering equipment directly impacts profitability and compliance. Our diaphragm filter press technology provides a clear competitive edge through measurable performance improvements.

Key Benefit | Loway Membrane Filter Press Performance | Value Proposition for Your Business |

Lowest Cake Moisture | The membrane squeeze function applies mechanical pressure (up to 16 bar or higher) to the cake. Achieves 15% to 30% moisture content, often 5-15% lower than conventional presses. | Reduced Disposal Costs: Lower moisture means less weight to transport and dispose of, leading to significant cost savings. |

Faster Cycle Times | The membrane squeeze cycle reduces filtration time by up to 50%. | Increased Throughput: Higher production capacity without increasing the machine footprint. |

Optimized Cake Washing | Allows for more effective cake washing and recovery of valuable filtrate. Perfect for chemical and mining applications. | Improved Product Recovery: Maximizes the yield of valuable materials, enhancing profitability. |

Flexible Operation | Variable squeeze pressure allows for process optimization based on slurry characteristics. | Process Versatility: Handles a wider range of slurries and ensures consistent results. |

Automated Efficiency | Our automatic membrane filter press systems feature PLC controls, automatic plate shifting, and drip tray integration for 24/7 operation. | Lower Labor Costs: Minimal operator intervention required, improving workplace safety and efficiency. |

Robust Plate Design | We use high-quality reinforced Polypropylene (PP) for our diaphragm filter press plates, ensuring durability under high-pressure inflation. | Lower total cost of ownership (TCO) |

Applications Across Industries

Our membrane plate filter press systems deliver reliable performance in demanding industrial environments:

- Mining & Minerals

Dewatering concentrates and tailings (e.g., copper, gold, iron ore) where low moisture is critical for transportation and processing.

- Tailings dewatering and management

- Concentrate thickening

- Mine water treatment

- Reduced environmental impact through lower moisture waste

- Chemical Processing and Pharmaceutical

Separation of fine chemicals, pigments, and pharmaceutical intermediates often requires superior cake washing capabilities.

- Catalyst recovery

- Pigment and dye filtration

- Fine chemical purification

- Waste volume reduction

- Environmental & Wastewater

Achieving the lowest possible moisture content in municipal and industrial sludge significantly reduces disposal volume and cost.

- Municipal sludge dewatering

- Industrial effluent treatment

- Drinking water clarification

- Landfill leachate processing

- Food & Beverage

Processing edible oils (like membrane filter press for palm oil), fruit juices, and brewing waste, where hygiene and material compatibility are paramount.

- Edible oil refining

- Starch recovery

- Brewery and distillery waste

- Fruit juice clarification

- Other Applications

- Pulp and paper industry

- Ceramic and clay processing

- Metal finishing wastewater

- Fine sand moisture removal for construction materials

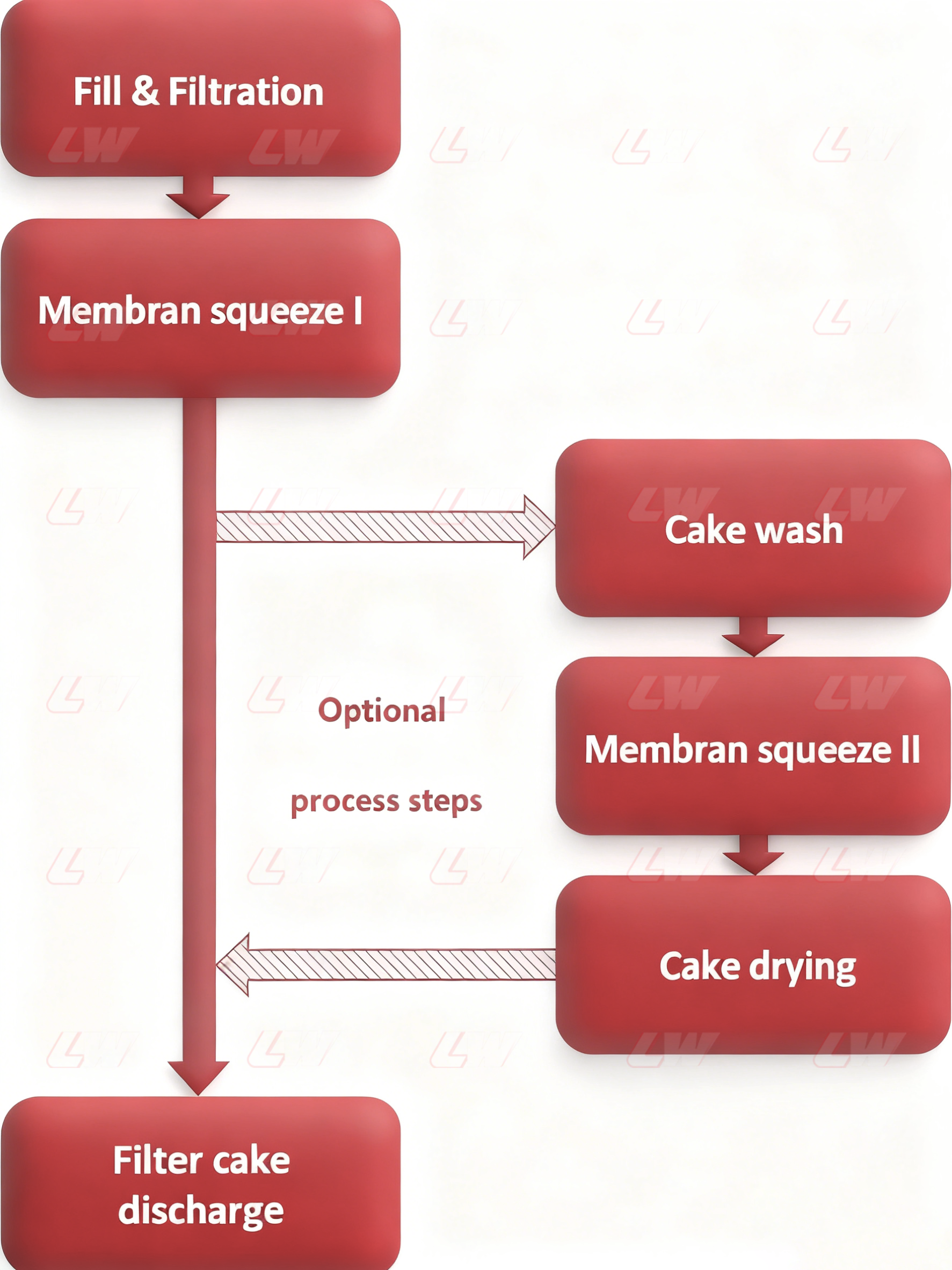

How the Membrane Squeeze Filter Press Works

Membrane Filter Press Working Principle

The core innovation of the membrane filter press working principle lies in the secondary dewatering stage. After the initial filtration phase, where slurry is pumped into the chambers and filtrate passes through the filter cloth, the membrane plates are inflated.

- Feeding: Slurry is pumped into the filter chambers at controlled pressure (0.6-1.0 MPa). Solids are retained by the filter press membrane cloth, forming a cake.

- Initial Filtration: Similar to a chamber press, filtrate passes through the cloth and exits the machine.

- Membrane Squeeze (The Key Difference): Once the feed pump stops, a squeezing medium (compressed air or water) is pumped behind the flexible membrane of the membrane plate (up to 2.0 MPa). This inflates the membrane, physically compressing the filter cake to squeeze out remaining moisture.

- Air Blow (Optional): High-pressure air is blown through the cake to remove final residual liquid.

- Discharge: Hydraulic system opens the plate pack, and the dry cake is discharged automatically. Automatic cloth washing system (optional) prepares for the next cycle

This two-stage process ensures maximum dewatering efficiency, making it the preferred solution for applications requiring the driest possible cake.

The squeezing pressure can be adjusted based on slurry characteristics, making this the ideal filter press to remove moisture from fine sand, sludge, or biological waste.

Get Your Custom Membrane Filter Press Solution

Technical Specifications

- Plate Sizes: 800mm, 1000mm, 1250mm, 1500mm, 2000mm.

- Squeeze Pressure: Standard 1.0 MPa (10 Bar), High Pressure up to 1.6 MPa (16 Bar).

- Squeezing Medium: Compressed Air or Water.

- Plate Material: Reinforced PP / TPE Membrane.

- Control System: Siemens/Schneider PLC.

X(AMYZ)G20-80/800-U(BK) diaphragm filter press technical parameter table | ||||||||||

Technical parameters: Cylinder working stroke 380, maximum stroke 410, filter plate size length × width × thickness: 800 * 800 * 60; | ||||||||||

Model | Filtration area | Diaphragm plate/ filter plate quantity (pieces) | Filter cake thickness | Filter chamber volume | Foundation size | Machine weight | Dimensions (mm) | |||

Length | Width | high | ||||||||

X(AMYZ)G20/800-U(BK) | 20 | 10 | 11 | 30 | 320 | 2380 | 2280 | 3080 | 1200 | 1150 |

X(AMYZ)G30/800-U(BK) | 30 | 15 | 16 | 480 | 3000 | 2830 | 3700 | |||

X(AMYZ)G40/800-U(BK) | 40 | 20 | 21 | 640 | 3620 | 3380 | 4330 | |||

X(AMYZ)G50/800-U(BK) | 50 | 25 | 26 | 800 | 4250 | 3930 | 4950 | |||

X(AMYZ)G60/800-U(BK) | 60 | 30 | 31 | 960 | 4880 | 4480 | 5580 | |||

X(AMYZ)G70/800-U(BK) | 70 | 35 | 36 | 1120 | 5500 | 5030 | 6200 | |||

X(AMYZ)G80/800-U(BK) | 80 | 40 | 41 | 1280 | 6130 | 5580 | 6830 | |||

X(AMYZ)G40-120/1000-U(BK) diaphragm filter press technical parameter table | ||||||||||

Technical parameters: working stroke 480, maximum stroke 510, filter plate size length × width × thickness: 1000mm * 1000mm * 70mm; | ||||||||||

Model | Filtration area | Diaphragm plate/ filter plate quantity (pieces) | Filter cake thickness | Filter chamber volume | Foundation size L | Machine weight | Dimensions (mm) | |||

Total length L | Width | high | ||||||||

X(AMYZ)G40/1000-U(BK) | 40 | 12 | 13 | 30 | 600 | 2829 | 4300 | 3630 | 1520 | 1400 |

X(AMYZ)G50/1000-U(BK) | 50 | 15 | 16 | 750 | 3255 | 4700 | 4050 | |||

X(AMYZ)G60/1000-U(BK) | 60 | 18 | 19 | 900 | 3681 | 5100 | 4480 | |||

X(AMYZ)G70/1000-U(BK) | 70 | 21 | 22 | 1050 | 4107 | 5500 | 4900 | |||

X(AMYZ)G80/1000-U(BK) | 80 | 24 | 25 | 1200 | 4513 | 5800 | 5330 | |||

X(AMYZ)G90/1000-U(BK) | 90 | 27 | 28 | 1350 | 4959 | 6250 | 5750 | |||

X(AMYZ)G100/1000-U(BK) | 100 | 30 | 31 | 1500 | 5385 | 6650 | 6180 | |||

X(AMYZ)G110/1000-U(BK) | 110 | 33 | 34 | 1650 | 5811 | 7050 | 6610 | |||

X(AMYZ)G120/1000-U(BK) | 120 | 36 | 37 | 1800 | 6237 | 7500 | 7030 | |||

X(AMYZ)G100-300/1250-U(BK) diaphragm filter press technical parameter table | ||||||||||

Technical parameters: working stroke 750, maximum stroke 830, filter plate size length × width × thickness: 1250mm*1250mm*72mm; | ||||||||||

Model | Filtration area | Diaphragm plate/ filter plate quantity (pieces) | Filter cake thickness | Filter chamber volume | Foundation size L | Machine weight | Dimensions (mm) | |||

Length | Width | high | ||||||||

X(AMYZ)G100/1250-U(BK) | 100 | 19 | 20 | 30 | 1500 | 4534 | 8800 | 5764 | 1600 | 1550 |

X(AMYZ)G110/1250-U(BK) | 110 | 21 | 22 | 1650 | 4846 | 9500 | 6074 | |||

X(AMYZ)G125/1250-U(BK) | 125 | 24 | 29 | 1875 | 5314 | 10200 | 6430 | |||

X(AMYZ)G140/1250-U(BK) | 140 | 27 | 28 | 2100 | 5782 | 11500 | 6835 | |||

X(AMYZ)G160/1250-U(BK) | 160 | 31 | 32 | 2400 | 6404 | 12500 | 7424 | |||

X(AMYZ)G180/1250-U(BK) | 180 | 34 | 35 | 2700 | 6874 | 13800 | 8104 | |||

X(AMYZ)G200/1250-U(BK) | 200 | 38 | 39 | 3000 | 7498 | 14500 | 8728 | |||

X(AMYZ)G225/1250-U(BK) | 225 | 43 | 44 | 3375 | 8220 | 15300 | 9228 | |||

X(AMYZ)G250/1250-U(BK) | 250 | 48 | 49 | 3750 | 9056 | 16700 | 10280 | |||

X(AMYZ)G300/1250-U(BK) | 300 | 57 | 58 | 4500 | 10614 | 18500 | 12010 | |||

X(AMYZ)G200-500/1500-U(BK) diaphragm filter press technical parameter table |

|

| |||||||||

Technical parameters: working stroke 800, maximum stroke 1000, filter plate size length × width × thickness: 1500mm * 1500mm * 80mm | |||||||||||

Model | Filtration area | Diaphragm plate/ filter plate quantity | Filter cake thickness | Filter chamber volume | Foundation size L | L2 size | Machine weight | Dimensions (mm) | |||

Length | Width | high | |||||||||

X(AMYZ)G200/1500-U(BK) | 200 | 25 | 26 | 30 | 3000 | 6225 | 18500 | 7450 | 2080 | 1960 | |

X(AMYZ)G224/1500-U(BK) | 224 | 27 | 28 | 3360 | 6720 | 19500 | 7945 | ||||

X(AMYZ)G250/1500-U(BK) | 250 | 30 | 31 | 3750 | 7256 | 21000 | 8481 | ||||

X(AMYZ)G280/1500-U(BK) | 280 | 34 | 35 | 4200 | 7875 | 225 | 9183 | ||||

X(AMYZ)G315/1500-U(BK) | 315 | 39 | 40 | 4725 | 8650 | 23500 | 9895 | ||||

X(AMYZ)G340/1500-U(BK) | 340 | 42 | 43 | 5100 | 9195 | 5000 | 25100 | 10420 | |||

X(AMYZ)G400/1500-U(BK) | 400 | 50 | 51 | 6000 | 10510 | 5500 | 28300 | 11740 | |||

X(AMYZ)G450/1500-U(BK) | 450 | 55 | 56 | 6750 | 11500 | 6000 | 30400 | 12730 | |||

X(AMYZ)G500/1500-U(BK) | 500 | 62 | 53 | 7500 | 12600 | 6500 | 32800 | 13885 | |||

Key Components and Quality Assurance

- Membrane Filter Press Plates: Our durable filter press membrane plate is manufactured from high-grade, chemically resistant materials, ensuring a long service life and minimal maintenance.

Material: Reinforced polypropylene (PP) or cast iron with PP coating

Membrane Type: High-elasticity rubber diaphragm (EPDM or natural rubber)

Design: Patented drainage channel system for faster filtrate removal

Durability: 3,000+ cycle lifespan under normal operating conditions

- Hydraulic System: Precision-engineered hydraulic closing system provides consistent, reliable pressure for safe operation.

Closing Force: 150-350 bar (customizable)

Control: PLC-automated with pressure sensors and safety interlocks

Speed: Fast close/open cycles reduce non-productive time

Protection: Automatic pressure relief and filter plate protection system

- Frame & Construction: heavy-duty carbon steel or stainless steel frame, built to withstand continuous, high-pressure industrial use.

Frame Type: Welded steel construction with corrosion-resistant coating

Footprint: Compact design optimized for space efficiency

Mobility: Optional skid-mounted type for flexible installation

Membrane Filter Press Design Considerations

When selecting a membrane squeeze filter press for your application, consider these critical factors:

Slurry Characteristics

• Solid particle size distribution • Solid concentration range • Chemical properties (pH, temperature, corrosivity) • Compressibility and settling rate

Performance Requirements

• Target cake moisture content • Required throughput (m³/hour or tons/day) • Cycle time constraints • Final cake handling method

Operating Environment

• Available floor space and headroom • Electrical power supply specifications • Compressed air or hydraulic fluid availability • Indoor vs. outdoor installation

Automation Level

• Labor availability and cost • Production shift patterns • Integration with existing process control systems • Maintenance capabilities

Precision Manufacturing and Quality Assurance

We understand that in industrial filtration, quality is non-negotiable. Our manufacturing process is centered on durability, efficiency, and compliance with international standards.

- Proprietary Plate Technology: We utilize advanced CNC machining to produce our membrane plate filter press components, ensuring perfect sealing, optimal filtration area, and extended lifespan for the filter press diaphragm plate.

- Robust Structural Integrity: All frames are constructed from high-grade steel, stress-relieved, and finished with industrial-grade anti-corrosion coatings, guaranteeing stability and longevity even in harsh operating environments.

- Global Component Sourcing: We integrate world-class components, including hydraulic systems and PLC controls, to ensure reliability and ease of local maintenance for our international clients.

Comprehensive Technical Service and Support

Our commitment to your operation begins long before installation and continues throughout the equipment’s lifecycle.

Service Advantage | Description | Value to the Customer (Engineer/Manager) |

Customized Slurry Testing | We conduct in-house laboratory testing of your specific slurry to determine optimal filtration parameters (pressure, cycle time, cake thickness). | Guarantees the delivered diaphragm filter press is perfectly sized and configured for your material, maximizing efficiency from day one. |

Expert Installation & Commissioning | Our certified engineers oversee installation, ensuring correct setup and seamless integration with your existing plant infrastructure. | Minimizes downtime and accelerates the path to full operational capacity. |

Operator Training & Documentation | Comprehensive on-site training for your technical team, covering operation, routine maintenance, and troubleshooting. | Empowers your staff to manage the equipment effectively, reducing reliance on external support. |

24/7 Aftermarket Support | Dedicated technical support for parts, maintenance, and emergency troubleshooting, ensuring continuous operation. | Protects your investment and minimizes the risk of costly production interruptions. |

Frequently Asked Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What is the main advantage of a membrane filter press over a standard chamber filter press?

The key benefit is significantly lower cake moisture content. The membrane squeeze action applies additional pressure after initial filtration, forcing out residual liquid that conventional filter presses cannot remove. This typically results in 5-15% lower moisture content, which translates to reduced disposal costs, faster downstream processing, and lower transportation expenses.

Q2: How does membrane filter press cloth selection affect performance?

Filter cloth selection is critical for optimal results. The cloth must match your slurry’s particle size, chemical properties, and operating temperature. We offer:

Monofilament cloths for easy cake release and cleaning

Multifilament cloths for fine particle retention

Needle-punched fabrics for high solids capture and rapid drainage

Our technical team can recommend the ideal cloth specification based on your application.

Q3: What is the typical lifespan of membrane filter press plates?

With proper operation and maintenance, our membrane plates typically last 3,000-5,000 filtration cycles. Factors affecting lifespan include:

Operating pressure levels

Slurry abrasiveness

Proper squeeze pressure settings

Regular inspection and maintenance

We provide detailed maintenance guidelines and offer replacement membranes with minimal downtime for installation.

Q4: Can I retrofit existing chamber filter presses with membrane plates?

In many cases, yes. Retrofitting depends on your current filter press frame design, hydraulic system capacity, and plate configuration. Our engineering team can assess your existing equipment and provide a feasibility analysis with cost estimates. Retrofitting can be cost-effective compared to purchasing entirely new equipment.

Q5: What maintenance does a membrane filter press require?

Regular maintenance includes:

Daily: Visual inspection of plates and cloths, check for leaks

Weekly: Filter cloth cleaning, hydraulic oil level check

Monthly: Membrane condition inspection, drainage port cleaning

Quarterly: Hydraulic system service, pressure calibration

Annually: Complete system inspection, gasket replacement as needed

We provide comprehensive maintenance manuals and training for your operators.

Q6: How do I determine the right size membrane filter press for my application?

Sizing depends on several factors:

Daily slurry volume to process

Desired cycle time

Target cake dryness

Available operating hours per day

Contact our sales engineering team with your process parameters. We’ll recommend the optimal configuration and can arrange pilot testing if needed to validate performance.

Q7: What is the typical price range for a membrane filter press?

Membrane filter press pricing varies based on:

Filter area and number of plates

Automation level (manual, semi-automatic, fully automatic)

Material of construction (PP, stainless steel, special coatings)

Additional features (cloth washing, cake discharge systems)

As a manufacturer, we offer competitive factory-direct pricing. Request a detailed quotation with your specific requirements for cost-effective solutions.

Q8: How much dryness can a membrane filter press achieve?

Membrane squeezing typically improves cake dryness by 5–15% compared with chamber presses, depending on the material. Achieves 15% to 30% moisture content.

Q9: Is it suitable for palm oil sludge?

Yes. Membrane presses are widely used in palm oil mills because membrane squeezing improves oil recovery and reduces waste volume.

Q10: What is the typical cycle time?

Depending on sludge type and configuration, cycle times usually range 10–60 minutes.

Q:11 Do you support OEM or turnkey projects?

Yes. Loway provides OEM manufacturing, engineering design, automation integration, and full system supply.

Q:12 Do you supply membrane filter presses for international markets?

Yes, Loway Equipment is an experienced membrane filter press exporter serving customers worldwide. We provide:

Export-standard packaging and documentation

Compliance with destination country regulations (CE, ASME, etc.)

English technical documentation and drawings

Installation supervision and commissioning support

International warranty and spare parts supply

Related Equipment & Complete Dewatering Systems

As a leading membrane filter press manufacturer and supplier, Loway Equipment is committed to providing tailored filtration solutions that drive down your operational costs and improve product quality.

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Filter Plates

From standard Recessed Chamber to high-pressure Membrane and CGR designs

Dewatering Screw Press

Continuous operation for efficient sludge treatment