Rotary Drum Screen (Integrated Fine Screen)

High-Performance Solid-Liquid Separation for Municipal & Industrial Wastewater

Combine screening, washing, and dewatering in a single compact unit. Engineered for precision capture rates and protection of MBR membranes and downstream pumps.

The Loway Rotary Drum Screen is a robust, all-in-one pretreatment solution designed to remove suspended solids, floating debris, and fibers from wastewater. By integrating a rotary drum filter with a screw conveyor press, this system delivers continuous filtration and significant volume reduction of screenings. It is the ideal “first line of defense” for protecting sensitive biological processes and membrane systems.

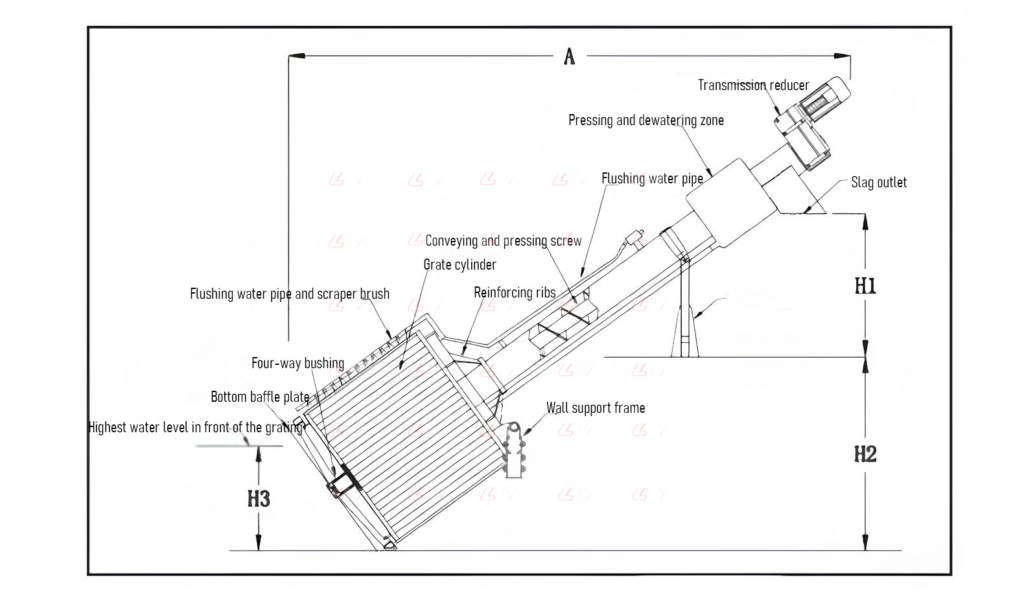

How It Works: The 3-Stage Integrated Process

Our Rotary Drum Screen operates on a continuous, fully automated cycle designed for maximum efficiency and minimal maintenance.

1. Filtration:

Wastewater flows into the drum basket. Solids larger than the selected gap (0.3mm–10mm) are trapped on the screen surface, while clean water passes through the mesh by gravity.

2. Transport & Cleaning:

As the drum rotates at a low speed, the captured solids are lifted to the top zone. A high-pressure spray system washes the organic matter back into the flow and dislodges the debris into the central trough.

3. Dewatering & Discharge:

The internal screw conveyor transports the screenings to the press zone. Here, the solids are compacted to remove excess water (achieving 25%-45% solid content) before being discharged, significantly reducing disposal volume and costs.

Engineered for Reliability and Efficiency

3-in-1 Compact Design:

Integrates filtration, conveying, and dewatering in one unit. This reduces the equipment footprint and simplifies civil work requirements.

Superior Corrosion Resistance:

All wetted parts and the drum mesh are manufactured from 304 or 316L Stainless Steel, ensuring long service life in aggressive sewage environments.

High Capture Efficiency:

With custom gap sizes ranging from 0.3mm to 10mm, the screen offers a fiber recovery rate of >80%, making it perfect for MBR pretreatment and industrial fiber recovery.

Intelligent Automation:

Equipped with a PLC control system that supports both Level Differential and Timer modes. It features overload protection and auto-reverse functions for unmanned, safe operation.

Self-Cleaning Operation:

The combination of drum rotation and high-pressure spraying prevents clogging, ensuring stable operation with low head loss and minimal energy consumption.

Standard Model Specifications

The table below represents standard LWZG models. We offer full customization for channel width, discharge height, and flow capacity based on your site conditions.

Model | LWZG-600 | LWZG-800 | LWZG-1000 | LWZG-1200 | LWZG-1400 | LWZG-1600 | LWZG-1800 | |

Drum diameter (mm) | Ø600 | Ø800 | Ø1000 | Ø1200 | Ø1400 | Ø1600 | Ø1800 | |

Standard screen length (mm) | 650 | 850 | 1000 | 1200 | 1400 | 1600 | 1800 | |

Conveying pipe diameter (mm) | 159 | 219 | 219 | 273 | 273 | 325 | 325 | |

High water level in front of the screen H3 (mm) | 400 | 500 | 650 | 800 | 900 | 1100 | 1250 | |

Standard installation angle (°) | 35° | 35° | 35° | 35° | 35° | 35° | 35° | |

Ordinary channel depth (mm) | 650~800 | 700~1000 | 900~1200 | 1100~1400 | 1200~1600 | 1400~1800 | 1800~2000 | |

Slag discharge height (mm) | 800~1200 | 800~1200 | 800~1200 | 800~1200 | 800~1200 | 800~1200 | 800~1200 | |

Motor power (kW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 3 | |

Water volume estimate (m³/h) | 1mm | 125 | 215 | 370 | 505 | 720 | 950 | 1205 |

2mm

| 190 | 330 | 555 | 765 | 1095 | 1440 | 1830 | |

3mm | 230 | 400 | 680 | 935 | 1340 | 1760 | 2235 | |

4mm | 235 | 430 | 720 | 1010 | 1440 | 2050 | 2700 | |

5mm | 250 | 465 | 795 | 1105 | 1575 | 2200 | 2935 | |

- Material: SS304 (Standard) / SS316L (Optional) / Frame available in Epoxy Coated Carbon Steel.

- Installation: Standard inclination is 35°, typically installed directly in the channel or a stainless steel tank.

Seamless Integration & Intelligent Control

At Loway Equipment, we engineer our Rotary Drum Screens to minimize civil work modifications and simplify the commissioning process for onsite contractors.

Flexible Installation Methods:

The equipment is designed to be installed directly into existing water channels at a standard 35-degree inclination angle, which can be adjusted according to specific site requirements. For facilities without existing concrete channels, the screen can be supplied pre-mounted within a custom steel tank enclosure, ensuring adaptability to diverse installation scenarios.

Plug-and-Play Setup:

Once the main frame is secured in place, installation is straightforward; operators simply need to connect the high-pressure flush water pipe and the electrical control panel to begin commissioning.

Precision Customization:

To perfectly match your specific water quality and flow rates, the screen gap size is fully customizable ranging from 0.3mm to 10mm. This precise engineering allows the equipment to achieve a solid-liquid separation efficiency with fiber recovery rates exceeding 80%.

Advanced PLC Automation:

Every unit is equipped with a PLC intelligent control system designed for completely unmanned operation. The system supports dual start/stop modes based on either time intervals or liquid level differentials. Built-in safety protocols include overload alarms and automatic shutdown protection to safeguard the motor and drive mechanism during abnormal conditions.

Rigorous Factory Testing:

Production strictly follows the ISO 9001 quality management system. The core drum filter is fabricated from 304 or 316L stainless steel utilizing advanced laser welding technology. To guarantee out-of-the-box reliability and eliminate operational risks, every single unit must pass a rigorous 72-hour continuous running test before leaving our facility.

Proven Performance Across Industries

Municipal Wastewater:

Headworks screening for Sewage Treatment Plants (STP) and protection of downstream pumps.

Membrane Protection (MBR/RO):

Fine screening (1mm-2mm) to prevent hair and debris from clogging sensitive membrane modules.

Food & Beverage / Slaughterhouses:

Removal of fruit peels, meat scraps, and fat.

Pulp & Paper:

Fiber recovery and reject separation.

Textile & Dyeing:

Interception of lint and fabrics.

Frequently Asked Questions

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: Can this Drum Screen be installed in my existing channel, or do I need a tank?

The Loway Rotary Drum Screen is highly flexible. It is designed to be installed directly into an existing concrete channel at a standard 35° to 45° inclination angle. If you do not have a channel, or for above-ground applications, we can supply the unit pre-mounted in a stainless steel tank (box), ready for pipe connection.

Q2: How do I choose the right gap size (slot size) for my application?

We offer customizable gap sizes ranging from 0.3mm to 10mm.

For MBR protection or fine fiber recovery (e.g., paper/textile), we recommend 0.3mm – 1.0mm.

For general municipal wastewater or slaughterhouse pretreatment, 1.0mm – 3.0mm is standard.

Q3: Does the screen require a backwash water source?

Yes. To prevent the mesh from clogging, the system uses a high-pressure spray bar. You need to connect a wash water source with a pressure of 0.3 – 0.6 MPa. This ensures that fibers and solids are effectively dislodged from the mesh and flushed into the screw conveyor.

Q4: How does the equipment handle high-grease or sticky wastewater?

The rotary drum design naturally minimizes clogging. However, for high-grease or high-viscosity applications (like food processing), we recommend increasing the flushing frequency of the spray system. The integrated screw press will then squeeze out the water and grease, discharging a dryer solid cake.

Q5: Can the screen handle hard solids like stones or metal parts?

No. The Rotary Drum Screen is designed for suspended solids, fibers, and organic debris. Strictly avoid introducing large hard objects like stones or metal blocks, as they can damage the fine screen mesh or the drum structure. For inlets with such risks, we recommend installing a Coarse Bar Screen upstream.

Q6: What is the maintenance routine for this equipment?

Maintenance is low. Routine tasks include:

Checking the spray water pressure to ensure effective cleaning.

Inspect the discharge outlet to ensure no blockage.

Verifying the electric control system and overload protection functions periodically.

Related Products

Belt Filter Press

Enhanced dewatering for difficult materials

Membrane Filter Press

High-Pressure Up to 25 bar for maximum dryness

Rotary Bar Screen

Designed for deep channels and high solid loads

Dewatering Screw Press

Continuous operation for efficient sludge treatment