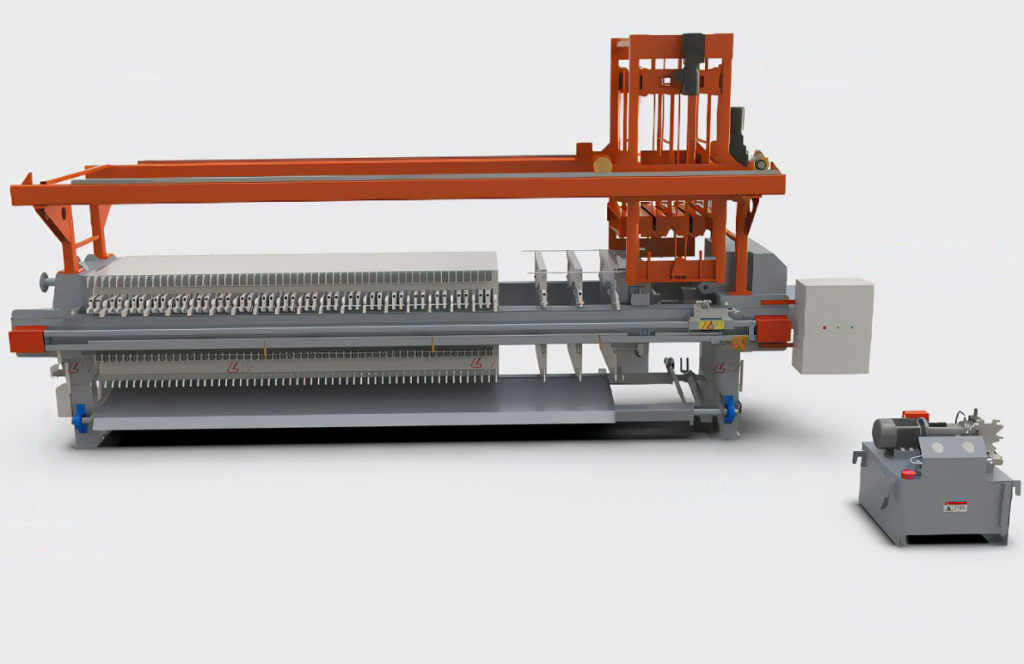

The filter press stands as one of industry’s most reliable and efficient solid-liquid separation technologies. Whether you’re in mining, chemical processing, wastewater treatment, or food and beverage production, understanding the precision engineering behind this workhorse equipment can help optimize your operations.

1. Plate Closure

Our hydraulic system delivers consistent, powerful clamping force across all filter plates, creating perfectly sealed filtration chambers. This crucial first step ensures zero leakage and optimal pressure distribution for maximum efficiency.

2. Feeding

Slurry material enters the system under carefully controlled pressure conditions. Our advanced feeding systems maintain optimal flow rates tailored to your specific material properties, balancing throughput with filtration quality.

3. Filtration

As pressure drives the slurry through the chambers, the engineered filter media allows liquid to pass while capturing solids. This core process builds a uniform filter cake within each chamber, with filtrate quality improving as the cake forms.

4. Washing (Optional)

For applications requiring higher purity, our systems offer customizable washing cycles. Clean water or specialized washing solutions circulate through the chambers, effectively removing impurities and soluble contaminants from the filter cake.

5. Air Blow (Optional)

Our compressed air systems deliver powerful yet controlled airflow to remove residual moisture from the filter cake. This optional step significantly reduces drying time and energy costs while improving cake consistency.

6. Plate Opening

The hydraulic system activates our proprietary quick-opening mechanism, precisely separating the plates in sequence. This engineered approach prevents jams and ensures smooth operation cycle after cycle.

7. Cake Discharge

Filter cake automatically discharges from the opened chambers with minimal operator intervention. Our discharge systems are designed for complete cake release, reducing manual cleaning requirements and increasing operational uptime.

8. Cloth Cleaning

Before beginning the next cycle, filter cloths undergo a thorough rinsing process. This critical maintenance step extends cloth lifespan and maintains consistent filtration performance across multiple cycles.

Stay ahead of the competition with these emerging trends in filtration technology:

IoT Integration – Real-time monitoring systems provide instant insights into filtration performance, pressure differentials, and maintenance needs. Connect your filter press to your digital infrastructure for unprecedented operational visibility.

Eco-Friendly Filtration Media – Sustainable operations begin with better materials. Our latest filter media options combine superior filtration performance with reduced environmental impact.

Advanced Materials – Revolutionary developments in plate and frame materials are enhancing durability while improving efficiency. These innovations translate directly to lower operating costs and extended equipment lifecycles.

Ready to Optimize Your Filtration Process?

Contact our team of filtration specialists today to discuss how our filter press solutions can address your specific solid-liquid separation challenges. From process assessment to custom configurations, we’re here to help you achieve maximum efficiency and product quality.

filter press price | sludge dewatering equipment supplier | filter press manufacturer| dewatering screw press | belt filter press | wastewater treatment equipments| wastewater treatment plants

schedule a consultation with our filtration experts