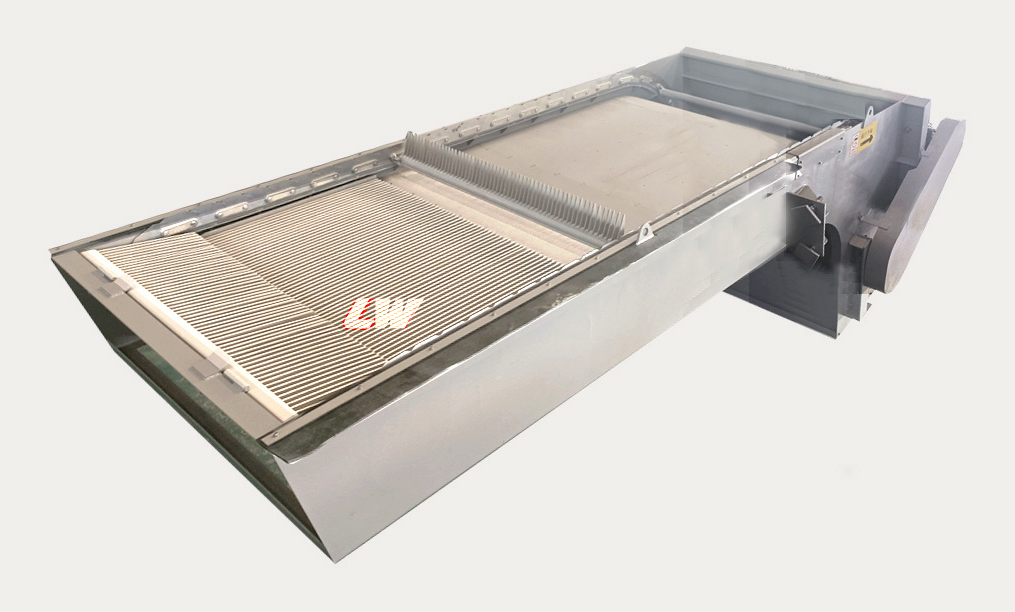

Bar Screen

Advanced Wastewater Treatment & Solid-Liquid Separation Solutions

The Bar Screen, also known as a rotary grid trash removal machine or solid-liquid separator, is an essential front-end wastewater screening solution designed to intercept and remove floating solids and debris from influent water. It is widely applied in municipal wastewater treatment plants, potable water facilities, as well as in various industrial processes for effective grit, rag, and sludge removal.

Bar screens serve as the primary treatment stage in wastewater processing, effectively removing large debris, solids, and floating materials before water enters subsequent treatment processes. Loway wastewater bar screens are engineered to handle varying flow rates and debris loads while maintaining consistent performance and minimal maintenance requirements.

The bar screen solid liquid separator technology incorporates automated cleaning mechanisms, reducing manual intervention and operational costs. These systems are essential components in sewage treatment plants, industrial wastewater facilities, and water reclamation systems, where reliable screening performance is critical for protecting downstream equipment.

Loway automatic bar screens feature robust construction with corrosion-resistant materials, ensuring long-term reliability in harsh wastewater environments.

The mechanical bar screen design incorporates precision-engineered components that deliver consistent screening efficiency while minimizing energy consumption and operational disruption.

Feature of Bar Screen

✅ High Screening Efficiency

Continuous screening of floating and suspended solids with minimal water bypass, ensuring downstream processes receive cleaner influent.

✅ Automatic Operation

Programmable control enables fully automatic cleaning cycles, with options for timed, level-differential, or manual actuation.

✅ Robust Overload Protection

Mechanical: Shear pin in the drive sprocket disengages under excessive load, safeguarding the transmission.

Electrical: Overcurrent relay in the control cabinet halts the motor to prevent burnout.

✅Self-Cleaning Rake Teeth

Unique tooth geometry and back-brushing action ensure solids are dislodged without manual scrubbing, reducing blockages and maintenance intervals.

✅ Corrosion Resistance

All submerged components (chain, raking teeth, guide wheels) are fabricated from stainless steel or corrosion-resistant polymers for extended service life.

✅ Quiet, Energy-Efficient Operation

Low noise under continuous operation and minimal power consumption relative to throughput capacity.

✅ Flexible Installation

Suitable for new installations or retrofits in existing channels, with tilting angles adjustable up to 75° and hydraulic lifts available for deeper reviers.

✅ Integrated Conveyor Option

When paired with a bar screen conveyor system, captured solids can be efficiently transported to dewatering or compaction modules, optimizing site layout and workflow.

Bar Screen Structure & Components

Structural Highlights

Compact Footprint

Optimized to occupy minimal channel width while maximizing flow-through area.Modular Design

Chain lengths and bar spacings (1–50 mm) can be customized per site requirements.Maintenance Access

Upper-side inspection hatches allow replacement of worn teeth and chain links on the platform, eliminating the need for underwater interventions

Raking Teeth Chain

A sealed chain assembly composed of high-strength nylon or stainless-steel raking teeth arranged at uniform intervals. The closed-loop chain travels through a guide track submerged in the influent channel, capturing solids bigger than the bar spacing.

Drive Unit

Electric motor coupled with a gearbox drives the chain via sprockets. The drive unit is protected by a weather-resistant cover, ensuring reliable operation in outdoor installations.

Support Frame

Heavy-duty structural steel frame forms the backbone of the unit. It supports both submerged and above-water components, with adjustable mounting flanges and rubber sealing strips to prevent leakage at the channel interface

Control Cabinet

Indoor-mounted control panel featuring start/stop, auto/manual, emergency stop, and overload protection functions. All electrical components are high-quality domestic or international brands, with PLC interface provisions available upon request.

Self-Cleaning Mechanism

At the chain’s discharge point, a cam track or back-guide induces relative motion between adjacent raking teeth to scrub off captured solids, which then fall into a collection hopper or onto a bar screen conveyor system for onward transport.

Sealing System

Rubber seals at sidewalls and bottom plates ensure tight sealing between the equipment and the channel, preventing bypass of solids and ensuring all influent passes through the screening bars.

Loway Bar Screen Technical Specifications

| Parameter | Typical Range / Value |

|---|---|

| Model Range | GSHZ 300–3600 (chain width 300 mm–3600 mm) |

| Bar Spacing Options | 1, 3, 5, 10, 20, 30, 40, 50 mm |

| Channel Depth | Standard 1.8 m (customizable) |

| Installation Angle | 75° (standard), adjustable 45°–90° |

| Drive Power | 0.75–15 kW (depending on model and load) |

| Chain Speed | 0.1–0.3 m/s (adjustable) |

| Material (Chain & Teeth) | 304/316 Stainless Steel or High-strength Nylon |

| Guide Wheels & Sprockets | Stainless Steel alloy or Polyurethane for quiet operation |

| Control Voltage | 380 VAC, 50 Hz (customizable for local standards) |

| Operating Temperature | –10 °C to +45 °C |

| Protection Grade | IP65 for motor & gearbox, IP54 for control cabinet |

| Power Consumption | 0.5–2 kWh per 1000 m³ throughput |

| Collection Hopper Volume | 20–100 L (depending on debris load and model) |

| Total Unit Weight | 200–2500 kg (depending on model size) |

Operation Process

Automated Control Modes

Timed Mode: Cleaning cycles every preset interval (e.g., every 5–15 minutes).

Level-Differential Mode: Activated when upstream water level rises by a set amount relative to downstream.

Manual Mode: Operator-initiated via control panel for maintenance or special cleaning.

1.Self-Cleaning Discharge

Upon reaching the top sprocket, the chain passes through a cleaning track or back-guide, inducing relative motion among teeth and dislodging the retained debris into a hopper or conveyor system.

2. Influent Screening

Raw wastewater enters the screening channel and flows through the bar gaps (e.g., 1 mm for micro bar screen applications, up to 50 mm for coarse solids). Suspended solids larger than the gap are retained by the raking teeth.

3. Raking Motion

The drive unit rotates the raking chain upward along the downstream side of the channel. Solids adhere to the teeth surfaces during this upward transit.

4. Conveyance of Screenings

A bar screen conveyor system (optional) carries the discharged solids to a designated collection point or transfer station, reducing manual handling.

5. Return Stroke

The cleaned chain returns submerged along the upstream side of the channel, ready for the next cycle. The entire process repeats continuously, adjustable based on flow conditions and solids load.

Industry Applications

Municipal Wastewater Treatment

Primary screening in sewage treatment plants, protecting downstream equipment and processes from debris damage.

Industrial Wastewater

Process water treatment in manufacturing facilities, removing production debris and protecting process equipment.

Pulp & Paper Industry

Removing fiber and wood debris from process water, protecting downstream clarification equipment.

Chemical Processing

Screening industrial process water to remove solid contaminants and protect treatment systems.

Power Generation

Cooling water intake screening, protecting heat exchangers and cooling systems from debris.

Food & Beverage Processing

Screening organic waste and food particles from processing wastewater before biological treatment.

Water Reclamation

Advanced screening for water reuse applications, ensuring high-quality reclaimed water production.

Storm Water Management

Combined sewer overflow screening, removing debris from storm water before discharge or treatment.

Why Choose Loway Bar Screen?

-

Customized Solutions:

From micro bar screens (1 mm spacing) for fine solids to heavy-duty coarse screens for large debris, tailored to your requirements.

-

Proven Reliability:

High uptime and minimal downtime thanks to self-cleaning design and dual overload protection.

-

Energy Savings:

Optimized chain speed and tooth geometry reduce power draw while maximizing screening capacity.

-

Low Lifecycle Costs:

Corrosion-resistant materials and minimal maintenance needs translate into lower total cost of ownership.

-

Comprehensive Support:

Professional pre-sales consultation, installation supervision, commissioning, and after-sales service ensure smooth project delivery.

How to Select the Right Bar Screen

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Channel Width (B) and Depth (H)

Desired Bar Spacing (b) based on solids size

Throughput Flow Rate (m³/h)

Lift Height (vertical distance between inlet and discharge)

Material Preferences (stainless steel grade, coating requirements)

How it works

We provide one-stop service of solid-liquid seporator planning, design, consultation, construction, equipment manufacturing, installation, commissioning and training. We are involved in complete sets of sludge dewatering projects for various industries.

Consultation what you need.

We do not aim to achieve maximum profit and do not reduce the quality of our products by catering to the market with low prices. We are happy to provide high quality tailor-made filtration equipment to you.

Production the filter press equipment for you

Our professional and advanced production technology, excellent manufacturing process, and perfect testing ensure that your equipment fully meets the quality acceptance standards.

Installation and commissioning equipment

Our skilled installation team installs this equipment for you in strict accordance with the construction drawings and construction process steps. Experienced technicians will debug and analyze the average results on site to achieve the best results and meet the needs of use.

After sales service

Our technicians patiently and meticulously answer all your questions and provide guidance and suggestions through messages, phone calls, videos, and arriving at the site.