Advanced Dewatering Screw Press for Efficient Sludge Treatment

Cost-effective, Continuous Operation Multi-Disc Screw Press for Municipal, Industrial& Food Processing Applications

Loway Equipment is a global screw press manufacturer delivers advanced dewatering screw press solutions engineered for superior solid-liquid separation across diverse industries.

Our multi-disc screw press technology combines robust construction with intelligent automation achieving exceptional dry solids content while minimizing polymer consumption and energy costs.

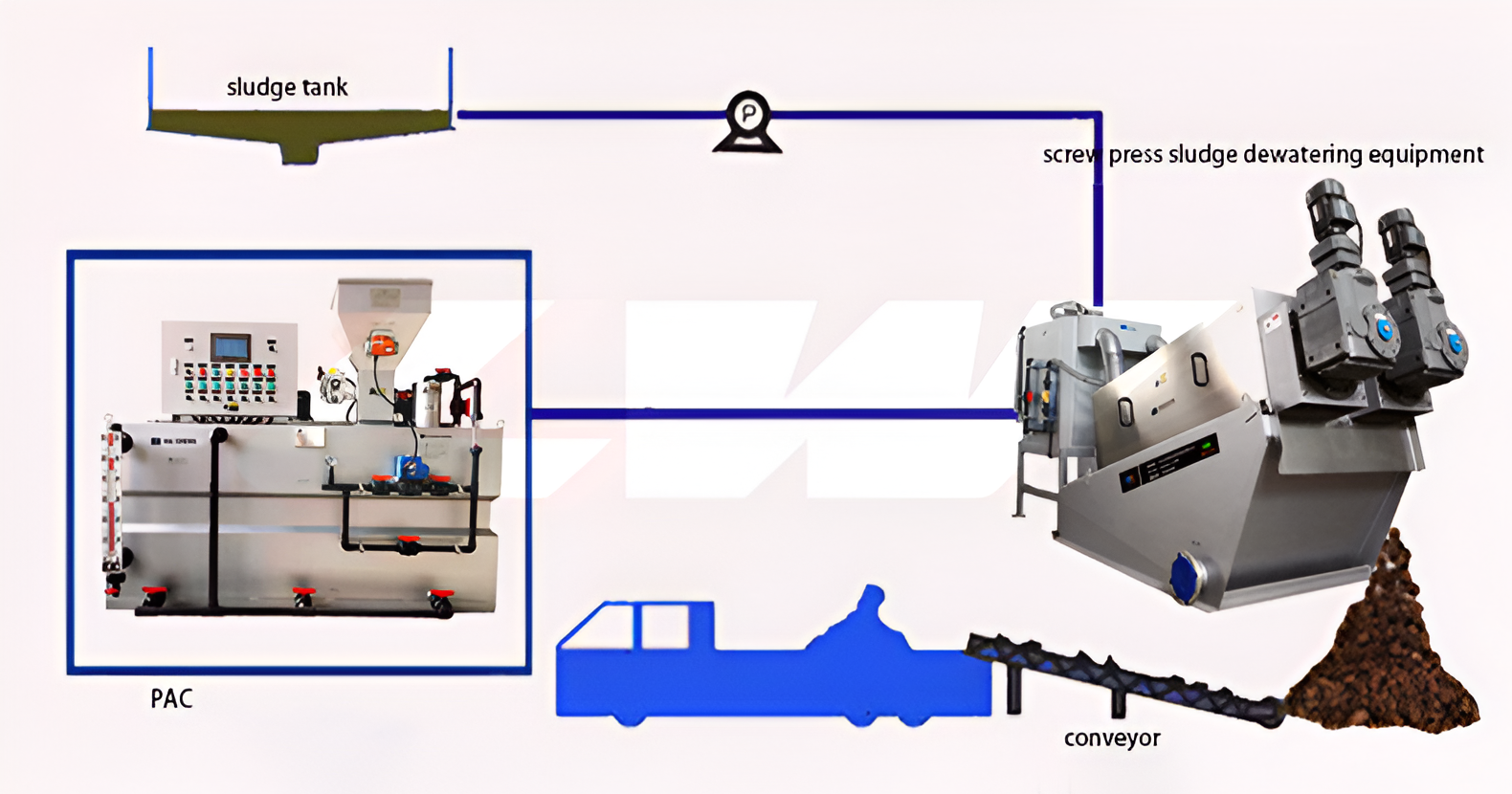

Whether processing municipal sludge, oily industrial waste, or organic materials, Loway’s sludge dewatering screw press delivers stackable cake output, minimal footprint, and 24/7 continuous and automated operation—reducing disposal costs and improving operational efficiency.

Muti-Plate Screw Press Key Feature

Superior Dewatering Performance

Loway industrial screw press systems are designed to solve the core problems of sludge treatment.

- Automatic & Clog-Free Operation

Fully enclosed system with PLC-based control enables unmanned operation with remote monitoring capabilities. The core drum, built with alternating fixed and moving rings, self-cleans with every rotation. This prevents clogging—even with oily sludge—and allows for 24/7, unattended operation.

- Low Energy Consumption

Cost-Effective Operation: Consumes 60-70% less energy compared to decanter centrifuges. Typical power consumption ranges from 0.75kW to 7.5kW depending on model, making it ideal for facilities seeking sustainable, economical sludge treatment solutions. This dramatically lowers your plant’s operational costs (OPEX).

- Low Maintenance & High Durability

Automated spray nozzle system prevents screen blinding and ring build-up. Wear-resistant stainless steel 304/316 construction extends service life and reduces replacement frequency.

- Compact Footprint

The small footprint dewatering system integrates thickening and dewatering into one unit, making it ideal for installations with limited space or for retrofitting existing facilities.

- Low Polymer Consumption

Advanced conditioning zone and precise polymer dosing system reduce flocculant requirements by 30-40% compared to other filter presses, lowering operational costs while maintaining excellent capture rates.

- Fully Enclosed Odor-Free Operation

Sealed dewatering chamber eliminates odor emissions and aerosol generation, meeting stringent environmental regulations and improving workplace safety

- Flexible Application Range

Multi-Industry Solution:

Municipal sewage sludge (activated & digested)

Food processing waste (fruit/vegetable pulp, dairy waste)

Pulp and paper sludge

Chemical and petrochemical sludge

Animal manure and agricultural waste

Oily sludge from refineries

Mining tailings and mineral processing waste

Working Principle & Dewatering Process

Technical Breakdown: Key Components

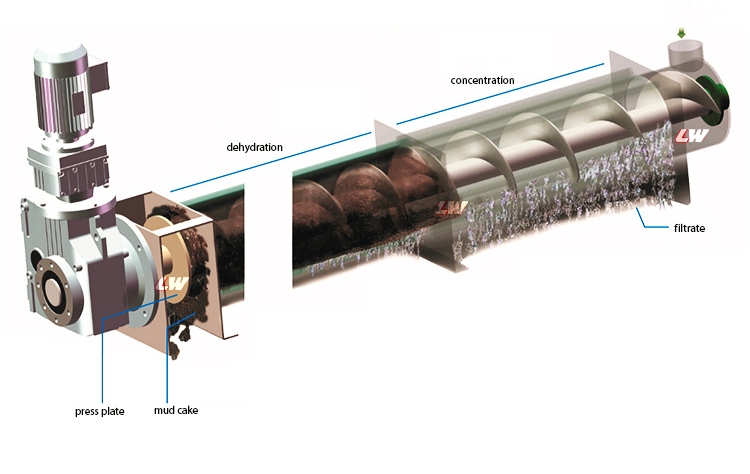

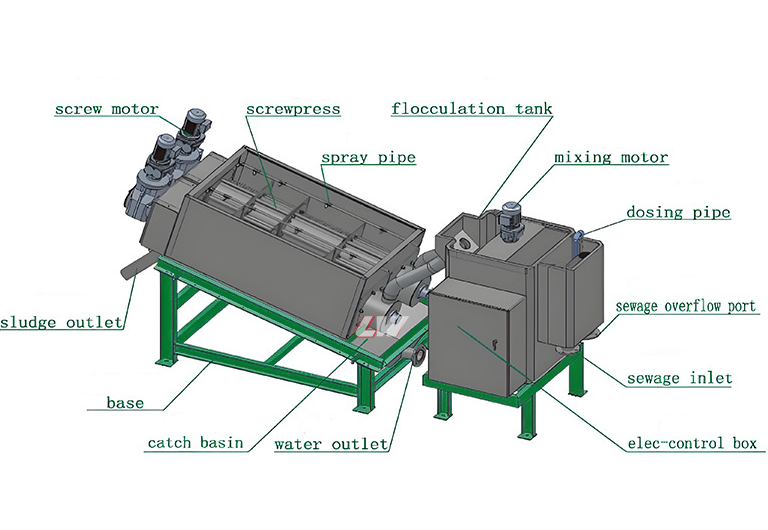

- 1. The Dewatering Drum (Core Assembly): The heart of the machine, composed of a central screw (auger) and a cylinder of stacked “rings.”

o Fixed & Moving Rings: These rings alternate. The moving rings oscillate, continuously cleaning the filter gaps, preventing clogging, and eliminating the need for high-pressure wash water.

o Filtrate Gaps: The precise gaps between rings allow water (filtrate) to escape while retaining solid particles.

- 2. The Main Screw (Auger Shaft): This screw transports sludge through the drum and applies increasing pressure. The pitch narrows toward the outlet, compressing the sludge to maximize dewatering.

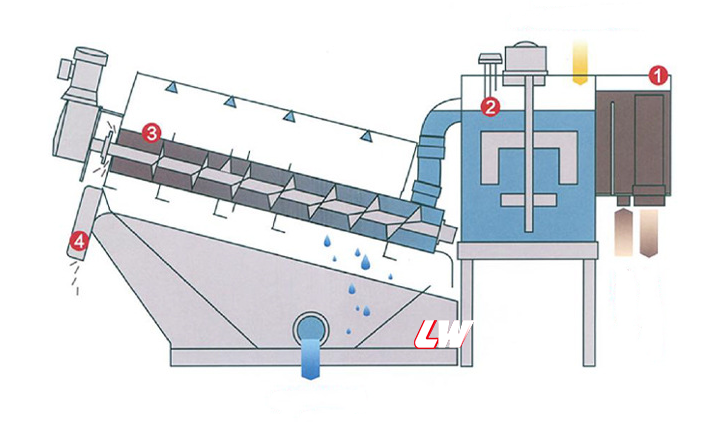

- 3. Integrated Flocculation Tank: Before dewatering, sludge is mixed with polymer in this tank (supported by a polymer dosing system) to form strong flocs essential for separation.

- 4. Control System (PLC): The entire process is automated. The PLC-controlled screw press panel manages the screw speed, polymer dosing, and the automatic washing system for seamless operation.

The 6-Stage Dewatering Process

The dewatering screw press operates on the principle of continuous mechanical compression, progressively removing water through a series of engineered zones:

- Feed & Conditioning Zone

Pre-conditioned sludge enters through the feed hopper at controlled flow rates. Inline polymer injection ensures optimal flocculation before entering the compression chamber. Variable speed feed pumps maintain consistent influent characteristics.

- Thickening Zone

Initial dewatering occurs as sludge encounters gradually decreasing pitch spacing. Free water drains through precision-slotted screen plates while solids begin consolidation. This gravity-assisted thickening reduces polymer demand downstream.

- Compression Zone

The heart of the screw press dewatering process—tapered screw shaft and narrowing screen cage create progressive pressure buildup. Moving rings rotate with the screw while fixed rings remain stationary, generating shear forces that break water-particle bonds.

- High-Pressure Extrusion Zone

Maximum compression occurs in the discharge section where pitch spacing reaches minimum clearance. Back-pressure adjustment cone fine-tunes final cake dryness, balancing torque limits with dewatering efficiency.

- Cake Discharge & Filtrate Collection

Dewatered cake exits as a stackable, non-sticky solid (18-28% DStypical), dropping into conveyors or hoppers. Filtrate drains continuously through screen perforations into collection troughs, returning to upstream clarification or being discharged to treatment.

- Automatic Cleaning Cycle

Programmable spray nozzles intermittently wash screen surfaces and ring gaps, preventing clogging and maintaining hydraulic capacity. Wash water consumption typically ranges 2-5% of filtrate volume.

Standard Performance Parameters

Model | DS Standard Treatment Capacity | Sludge Treatment Capacity | |||||

5000mg/L | 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

LWSP-101 | 4 – 8kg/h | 0.8t/h | 0.5t/h | 0.3t/h | 0.25t/h | 0.2t/h | 0.1t/h |

LWSP-131 | 6 – 15kg/h | 1.6t/h | 1.2t/h | 0.7t/h | 0.5t/h | 0.3t/h | 0.2t/h |

LWSP-132 | 15 – 25kg/h | 3.0t/h | 2.0t/h | 1.4t/h | 1.0t/h | 0.7t/h | 0.5t/h |

LWSP-201 | 15 – 20kg/h | 3.0t/h | 1.8t/h | 1.5t/h | 1.0t/h | 0.6t/h | 0.3t/h |

LWSP-202 | 30 – 45kg/h | 5.0t/h | 3.0t/h | 2.8t/h | 1.9t/h | 1.2t/h | 0.6t/h |

LWSP-203 | 30 – 60kg/h | 9.0t/h | 6.2t/h | 4.0t/h | 2.8t/h | 1.6t/h | 0.8t/h |

LWSP-301 | 50 – 70kg/h | 9.0t/h | 6.0t/h | 3.0t/h | 2.5t/h | 1.8t/h | 0.9t/h |

LWSP-302 | 100 – 140kg/h | 16.0t/h | 12.0t/h | 6.0t/h | 4.8t/h | 3.5t/h | 2.4t/h |

LWSP-303 | 150 – 210kg/h | 25.0t/h | 18.0t/h | 9.0t/h | 7.0t/h | 4.5t/h | 3.5t/h |

LWSP-304 | 200 – 280kg/h | 35.0t/h | 24.0t/h | 12.0t/h | 9.5t/h | 6.0t/h | 4.8t/h |

LWSP-401 | 140 – 200kg/h | 30.0t/h | 18.0t/h | 10.0t/h | 6.0t/h | 3.5t/h | 3.0t/h |

LWSP-402 | 250 – 350kg/h | 60.0t/h | 30.0t/h | 15.0t/h | 10.5t/h | 7.0t/h | 6.0t/h |

LWSP-403 | 320 – 500kg/h | 90.0t/h | 45.0t/h | 23.0t/h | 16.0t/h | 11.5t/h | 9.0t/h |

LWSP-404 | 500 – 700kg/h | 120.0t/h | 60.0t/h | 32.0t/h | 20.0t/h | 16.0t/h | 12.0t/h |

Dewatering Performance:

Cake solids content: 18-28% DS (depending on sludge type and polymer dosing)

Solid capture rate: ≥95% (with proper conditioning)

Cake characteristics: Stackable, non-sticky, transport-ready

Filtrate TSS: Typically <500 mg/L (recirculation acceptable)

Operating Conditions:

Feed sludge concentration: 0.3-5% DS (3,000-50,000 mg/L)

Polymer dosing rate: 3-8 kg active polymer per ton DS (40-60% lower than belt press)

Screw speed: 1-5 RPM (variable depending on model and application)

Operating pressure: Self-generating, 0.3-0.8 MPa at discharge

Ambient temperature range: -10°C to +45°C (optional heating for cold climates)

Customization Options:

Material upgrades: SS316L, duplex stainless, or exotic alloys

Cold climate package: Insulated housing, heating cables, antifreeze lines

Explosion-proof motors and wiring (ATEX/IECEx for hazardous areas)

Dual-train configuration for redundancy and maintenance flexibility

Mobile trailer-mounted units for temporary or emergency dewatering

Turnkey Solutions: Loway can provide complete sludge management systems integrating multiple technologies for optimal performance.

How Loway Builds World-Class Screw Press Equipment

Key Design Features Enabling Performance

Variable Pitch Screw Shaft Precision-machined helical flights with decreasing pitch create controlled pressure gradients. CNC manufacturing ensures uniform compression and prevents channeling.

Floating Ring Technology Spring-loaded compression rings adapt to material variations, maintaining optimal gap clearance (typically 0.3-0.8mm) between moving and fixed components. This self-adjusting mechanism prevents over-compression damage.

Perforated Press Cage Laser-cut stainless steel screens with optimized hole patterns (0.3-1.0mm diameter, 30-40% open area) maximize filtrate flow while retaining solids. Wedge-wire construction resists blinding and extends operational intervals.

Torque-Limiting Drive System Heavy-duty gearbox with overload protection prevents mechanical damage during feed surges or foreign object intrusion. Variable frequency drives enable speed optimization for different sludge types.

Precision Engineering Meets Reliable Performance

As a dedicated screw press manufacturer, we don’t just assemble components—we build your solution. Our ISO-certified manufacturing process ensures every machine meets the highest standards of quality, reliability, and performance.

- Raw Material Verification: We start with certified, high-grade raw materials, including SS304 and Stainless Steel 316, from trusted suppliers.

- Precision Component Fabrication: We use high-precision laser cutting for the rings and dynamic balancing for the screw auger to ensure uniform gaps, minimal vibration, and exceptional wear resistance.

- Expert Welding & Assembly: Our certified welders and technicians fabricate the frame and assemble the core dewatering drum with micrometer precision.

- Factory Acceptance Testing (FAT): No unit leaves our factory without testing. Every press undergoes a comprehensive FAT, including water tests and full functional checks of the motor and PLC.

- Professional Packaging: The finished unit is crated for international sea freight, ensuring your industrial dewatering equipment arrives safely and ready for installation.

Applications Across Industries

Loway dewatering equipment is trusted by clients globally for a wide range of applications. We provide specialized wastewater dewatering solutions for:

- Municipal Sludge Dewatering (Wastewater Treatment Plants)

- Industrial Wastewater Treatment

- Food Processing Wastewater (Including food waste screw press and fruit juice screw press applications)

- Petrochemical Sludge (Especially oily sludge)

- Textile Dyeing Sludge

- Pulp and Paper Sludge

- Agricultural Sludge Dewatering (e.g., animal manure dewatering)

- Mining Tailings Dewatering

- Pharmaceutical Wastewater Treatment

Municipal Wastewater Treatment

Municipal Sludge Screw Press Solutions

Loway dewatering screw presses are widely deployed in municipal WWTPs worldwide, processing activated sludge, digested biosolids, and combined sewage sludge streams.

Typical Applications:

Primary and secondary clarifier underflow thickening

Waste-activated sludge (WAS) dewatering post-digestion

Screenings and grit dewatering

Septage receiving station solids separation

Performance Benefits:

Reduces biosolids trucking costs by 60-75% through volume reduction

Achieves 20-25% cake solids (activated sludge) and 25-28% (digested sludge)

Low odor operation improves community relations

Minimal operator attention required—ideal for small to mid-size plants

Food & Beverage Processing

Food Waste Screw Press for Organic Material Recovery

From fruit and vegetable processing to dairy operations, our screw press dewatering systems efficiently separate solids for composting, animal feed, or energy recovery.

Suitable Materials:

Fruit and vegetable pulp (juice extraction residues)

Brewery spent grain and trub

Winery pomace and lees

Dairy processing sludge

Slaughterhouse waste and rendering plant sludge

Coffee grounds and tea waste

Industry Advantages:

Food-grade SS316 construction meets sanitary standards

Easy-clean design for CIP (clean-in-place) integration

Recovers valuable proteins and fibers for by-product sales

Reduces waste disposal costs and environmental footprint

Pulp & Paper Industry

Screw Press for Pulp Thickening and Sludge Dewatering

Paper mills generate massive volumes of fiber-laden sludge from de-inking, pulp washing, and wastewater treatment. Our screw press systems handle high-consistency fiber suspensions efficiently.

Applications:

Primary clarifier fiber recovery (white water treatment)

De-inking sludge dewatering

Biological treatment sludge (activated sludge from pulp mill WWTP)

Coating and filler recovery

Technical Specifications for Paper Industry:

Handles consistency from 2-8% up to 20-30% cake solids

Fiber recovery rate >98%

Reduced fiber loss to effluent saves raw material costs

Compact design fits into congested mill environments

Chemical & Petrochemical

Chemical Sludge Screw Press for Hazardous Material Handling

Refineries, chemical plants, and oil & gas operations generate oily sludge, catalyst fines, and hazardous waste streams requiring specialized dewatering.

Materials Processed:

Oily sludge from API separators and tank bottoms

Petrochemical wastewater treatment sludge

Catalyst and filter cake from chemical synthesis

Paint booth sludge and coatings waste

Corrosion-Resistant Features:

SS316L or duplex stainless construction

Chemical-resistant seals and coatings

Explosion-proof electrical components for Class I, Div 1 areas

Closed-loop wash water system for hazardous containment

Safety & Compliance:

Fully enclosed design prevents VOC emissions

Integrated safety interlocks (emergency stops, overload protection)

Meets OSHA, EPA, and international safety standards

FREQUENTLY ASKED QUESTIONS

Have More Questions? Our technical team is ready to provide detailed, personalized guidance.

Q1: What pre-treatment or conditioning is required?

Polymer Conditioning (Recommended for Most Applications):

- Anionic or cationic polymer selection based on sludge zeta potential

- Dosing rate: 3-8 kg active polymer per ton dry solids

- Inline static mixer or dynamic flocculator ensures uniform mixing

- Aging time: 30-60 seconds before entering the screw press

pH Adjustment (Case-Specific):

- Acidic or alkaline industrial sludges may require pH neutralization (6.5-7.5 optimal)

- Lime addition for phosphate precipitation in some applications

Screening (If Needed):

- Coarse screens (5-10mm) remove rags, plastics, or large debris

- Fine screens (1-3mm) optional for grit-heavy applications

No Pre-Treatment Needed:

- Digested biosolids often dewater without polymer (depending on digester performance)

- Some food wastes with high natural fiber content

Our engineering team provides jar testing and pilot trials to determine optimal conditioning requirements for your specific sludge.

Q2: Can the system operate automatically without constant supervision?

Yes—Loway screw presses feature advanced automation:

PLC Control System:

- Pre-programmed operating sequences for start-up, normal run, cleaning, shutdown

- Automatic parameter adjustment based on real-time sensor feedback

- Recipe storage for multiple sludge types (switch with one button)

Integrated Sensors:

- Torque monitoring: Prevents overload, adjusts speed or back-pressure automatically

- Filtrate turbidity: Signals inadequate polymer dosing or equipment malfunction

- Temperature: Alerts to bearing wear or motor issues

- Vibration: Early warning of imbalance or mechanical problems

Remote Monitoring:

- SCADA integration via Modbus RTU/TCP, Profinet, or OPC-UA

- Email/SMS alarms for fault conditions

- Historical data logging for performance trending

- VPN remote access for diagnostics (optional)

Automated Maintenance:

- Self-cleaning spray cycles (programmable interval/duration)

- Automatic polymer dosing adjustment

- Predictive maintenance alerts based on runtime hours

Typical Operation: Operator checks system 1-2 times per shift, performs weekly/monthly preventive maintenance. System runs unmanned overnight and weekends.

Q3: How do I maintain the screw press? What are the wear parts?

Routine Maintenance (Weekly/Monthly):

✅ Visual Inspection: Check for leaks, unusual noise, vibration

✅ Spray Nozzle Check: Ensure all nozzles spray properly, clean if clogged

✅ Lubrication: Grease bearings per schedule (auto-lube systems available)

✅ Polymer System: Verify dosing pump operation, check chemical inventory

✅ Filtrate Quality: Sample and test TSS, adjust polymer if needed

Quarterly/Semi-Annual Maintenance:

🔧 Drive System: Check belt tension, coupling alignment, gearbox oil level

🔧 Electrical: Tighten connections, inspect cable insulation

🔧 Seals & Gaskets: Replace if showing wear or leakage

🔧 Calibration: Verify sensor accuracy (torque, flow meters)

Annual Maintenance:

🔧 Ring Inspection: Measure gap clearances, replace worn rings

🔧 Screen Cage Check: Inspect for hole plugging or damage

🔧 Bearing Replacement: Per manufacturer schedule (typically 8,000-15,000 hours)

🔧 Complete Cleaning: Disassemble and deep-clean all components

Q4: What is the typical lifespan of a screw press system?

Equipment Lifespan:

- Mechanical life: 15-20 years with proper maintenance

- Major overhaul: Recommended at 8-10 years (bearing replacement, screen refurbishment)

- Economic life: 10-15 years before considering upgrade to newer technology

Q5: What warranty and after-sales support do you provide?

Standard Warranty Coverage:

Equipment Warranty: 18 months from commissioning OR 24 months from shipment (whichever comes first)

- Covers manufacturing defects in materials and workmanship

- Free replacement of defective parts (freight charges apply)

- Remote technical support during warranty period

Extended Warranty Options:

- 36-month coverage available for 5-10% premium

- Wear parts excluded (rings, bearings, seals)

After-Sales Support:

✅ Technical Hotline: 24/7 phone/email support in English, Spanish, Chinese

✅ Remote Diagnostics: VPN access for PLC troubleshooting

✅ Video Guidance: Live video calls for maintenance procedures

✅ Spare Parts: Stocked in regional warehouses (North America, Europe, Asia)

✅ On-Site Service: Field technicians available for commissioning, training, repairs

✅ Preventive Maintenance Contracts: Annual agreements with guaranteed response times

✅ Operator Training: Comprehensive O&M training during commissioning (3-5 days)

✅ Documentation: Detailed manuals in English + your local language (on request)

Spare Parts Availability:

- Critical wear parts: 2-week delivery globally

- Standard components: 4-6 week lead time

- Emergency service: 48-72 hour expedited shipping available

Service Network:

- Direct factory support from China

- Authorized service partners in 15+ countries

- Local distributors for routine maintenance supplies

Q6: What documentation and certifications come with the equipment?

Standard Documentation Package:

📄 Operation & Maintenance Manual: Comprehensive guide with troubleshooting, maintenance schedules, parts lists

📄 Electrical Drawings: Single-line diagrams, panel layouts, wiring schematics

📄 Mechanical Drawings: Assembly drawings, foundation plans, piping diagrams

📄 Quality Certificates: Material test reports (MTRs), welding procedure specifications (WPS), NDT reports

📄 FAT Protocol & Report: Factory test results, performance data

📄 Spare Parts List: Recommended inventory with part numbers and pricing

Get Your Custom Dewatering Solution

Our team can help you select the ideal screw press for wastewater treatment based on your specific sludge type, flow rate, and dryness requirements.

Contact us for a free technical consultation and to discuss your configuration options.

Get a Free Consultation & Quote

Related Equipment & Complete Dewatering Systems

Complementary Products:

- Dewatering Screw Press ← You are here

- Filter Press Equipment

- Belt Filter Press

- Bar Screen

Resources:

- Technical Library

- Case Studies

- Installation Videos

- Maintenance Guides